Seepex Range Pump-PMV Pump

The Benefis of Seepex Range Pump

The Description of Seepex Pump

Seepex Pump is a renowned manufacturer and supplier of progressive cavity pumps, offering innovative solutions for efficient fluid handling. With a strong focus on reliability, performance, and versatility, Seepex Pump has established itself as a trusted name in the industry.

Seepex Pump progressive cavity pumps are designed to handle a wide range of fluids, including viscous, abrasive, shear-sensitive, and chemically aggressive substances. These pumps feature a unique design that ensures gentle and pulsation-free fluid transfer, making them ideal for various applications in industries such as wastewater treatment, food and beverage, chemical processing, and oil and gas.

One of the key advantages of Seepex Pump is its commitment to customization. They understand that each customer’s requirements are unique, and therefore offer a wide range of options to tailor their pumps to specific needs. From different materials of construction to various sealing options, customers can choose the configuration that best suits their application.

In addition to its exceptional product quality, Seepex Pump also provides comprehensive after-sales support. Their team of experts is readily available to assist customers with installation, maintenance, and troubleshooting, ensuring smooth operation and minimal downtime.

Seepex pumps find extensive application across various industries due to their exceptional performance and versatility. These pumps excel in handling a wide range of fluids, including viscous, abrasive, and shear-sensitive substances. With their robust design and advanced technology, Seepex pumps are commonly used in applications such as chemical processing, wastewater treatment, food and beverage production, oil and gas, pharmaceuticals, and many more. Whether it’s transferring, dosing, or metering liquids, Seepex pumps ensure efficient and reliable fluid handling, making them a preferred choice for diverse industrial processes.

When it comes to customizing Seepex pumps, several key factors need to be considered to ensure optimal performance. These factors include the medium being pumped, the desired flow rate, the required pressure, and the voltage specifications for the country of use. Seepex offers a comprehensive range of pump options to accommodate different media viscosities, from low to high, ensuring efficient fluid handling. By specifying the desired flow rate and pressure requirements, Seepex can tailor the pump design to meet specific application needs. Additionally, considering the voltage specifications of the country where the pump will be used is crucial to ensure compatibility and safe operation. With these considerations in mind, Seepex delivers customized pump solutions that deliver reliable and efficient performance in various industrial settings.

Seepex pumps offer exceptional performance and reliability, making them a preferred choice for various industrial applications. With their innovative design and advanced features, Seepex pumps deliver efficient and precise pumping solutions.

Versatile Pumping Capability: Seepex pumps are designed to handle a wide range of liquids, including viscous, abrasive, and shear-sensitive fluids. They can effectively pump substances with varying consistencies, ensuring smooth and consistent flow rates.

Customizable Design: Seepex pumps can be tailored to suit specific application requirements. From material selection to pump configuration, customers have the flexibility to customize their pumps for optimal performance in their unique operating conditions.

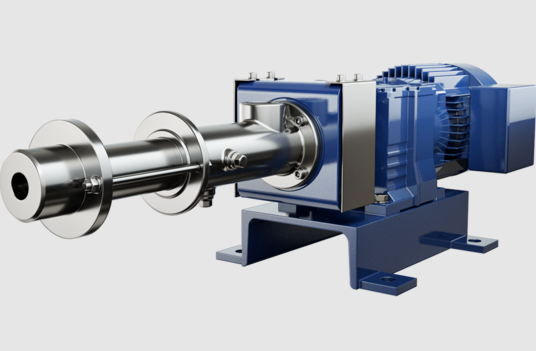

Progressive Cavity Technology: Seepex pumps utilize progressive cavity technology, which ensures gentle product handling and minimal pulsation. This feature is particularly beneficial for delicate and sensitive fluids, preventing damage and maintaining product integrity.

High Efficiency and Energy Savings: Seepex pumps are engineered for high efficiency, minimizing energy consumption and reducing operating costs. Their precise volumetric control and low-shear operation contribute to improved overall system efficiency.

Easy Maintenance and Serviceability: Seepex pumps are designed with user-friendly features that simplify maintenance and minimize downtime. Quick disassembly and reassembly, along with readily accessible components, enable efficient servicing and reduced maintenance costs.

Robust Construction and Durability: Seepex pumps are built to withstand demanding industrial environments. With rugged construction and high-quality materials, they offer long-lasting performance and reliability, ensuring minimal downtime and extended service life.

The Benefis of Seepex Range Pump

People Also Ask

Material Optional: SS304/SS316L/DSS/Tool Steel Plating Optional: Cr Plating/Tungsten Carbide Include Sealing Covers, Retaining Sleeves, Coupling Rod Pins, Snap Rings, O-rings, etc. Mechanical: Long life, good anti-viberation Packing seal: low cost, easy to install&replace Universal Parts Available for SEEPEX Pump Models PMV Pump can supply the whole set of replaceable parts for SEEPEX progressing cavity pumps….

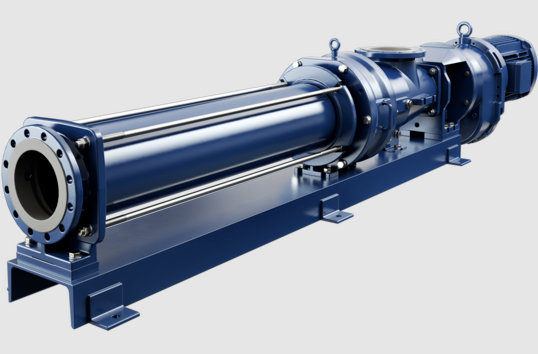

SEEPEX Progressive Cavity Pumps SEEPEX progressive cavity pumps are highly efficient and reliable pumping solutions. They are designed to handle a wide range of fluids, including viscous and abrasive substances. With their unique design and advanced technology, SEEPEX pumps deliver consistent performance, low pulsation, and gentle product handling, making them ideal for various industries such…

Introduce Seepex Pumps Parts With a focus on precision engineering and superior performance, Seepex Pumps Parts offers a wide range of products, including stators, rotors, coupling rods, and drive shafts. Their products are designed to meet or exceed OEM specifications, ensuring optimal pump performance and reliability. Seepex Pumps Parts is committed to providing exceptional customer…

Description of Seepex Pump Drawings SEEPEX pump drawings are comprehensive technical representations that provide detailed insights into the design and construction of SEEPEX pumps. These drawings offer a visual representation of the pump’s components, dimensions, and installation requirements, serving as an invaluable resource for engineers, technicians, and maintenance personnel. Application of Seepex Pump Drawings SEEPEX…

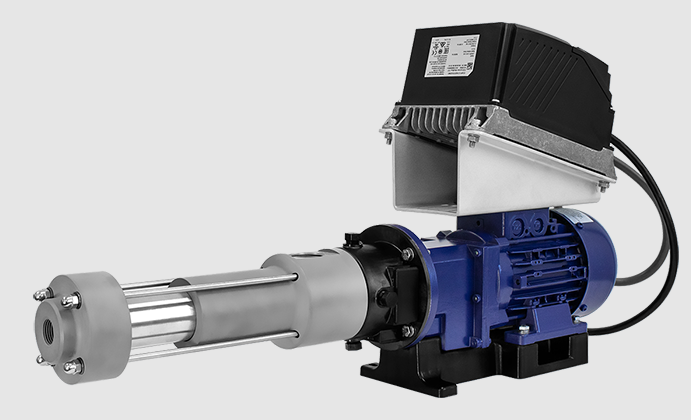

MDR – Superior Process Control The MDR range design incorporates an external GA seal arrangement and engineered composite seal housing, lantern, and rotating unit. The only metallic part of the pump that is exposed to the conveyed product is the rotor. This design allows for broad chemical compatibility, increased performance, and decreased maintenance. The patented…

DESIGNED WITH THREADED CONNECTIONS FOR GENERAL METERING APPLICATIONS MD Range progressive cavity pumps are used in virtually all industries for metering and dosing precise quantities. They are particularly good for minimal pulsation conveyance of thin to viscous fluids, as well as corrosive media containing solids. People Also Ask