The Description of Seepex Range Pump

BTE = Features a feed hopper and a compression zone with an enlarged cross-section as well as an auger feed screw with a longer pitch and enlarged diameter. The length of the hopper opening is variable to suit the application conditions. Pumps of this range are used for pumping highly viscous to airtight products that do not tend to bridging.

BTI = Pumps of the BTI range feature a rectangular feed hopper with integrated bridge breaker. The compression housing is dismountable for service work. The length of the hopper opening is variable to suit the application conditions. Pumps of this range are used for pumping highly viscous to airtight products that tend to form bridges above the auger feed screw.

BTH = The BTH range combines the various advantages of product group T. It is characterized by a separately driven, concentrically rotating ribbon screw with a maximized diameter and a long pitch. Through separate control of the conveying screw speed, the BTH pump can be used for almost any conveying media. The variable speed auger screw permits optimum filling of the conveying elements rotor and stator without causing excess capacity in the stuffing box. Even media that tend to form bridges can be handled with ease due to the large screw diameter of the BTH pump. The BTH range is the technical optimum solution for shear sensitive conveying media.

BTHE = Pumps of the BTHE range feature a feed hopper with vertical hopper walls and a ribbon screw rotating centrically and on the edges. This guarantees optimum emptying of the feed hopper and optimised feed of the medium into the conveying elements of the pump. The length of the hopper opening is variable to suit the respective application conditions.

BTES = The BTES range is equipped with a shut-off system and Range BTES ensures replacement of the conveying elements with the silo filled

BTEI = The BTEI range is a further development of the proven BTI and BTE ranges. In addition to a bridge breaker/mixing device, it features a supply tank that can be adapted to the application conditions on site. This supply tank replaces a separate storage tank and thus saves space within the system.

The Parameter of Seepex Range Pump

| Manufacturer: | PMV Pump |

| Max Flow: | 500 M3/HOUR |

| Max Head: | 48 BAR |

| Model: | Seepex Range Pump |

| MPN: | Seepex Range Pump |

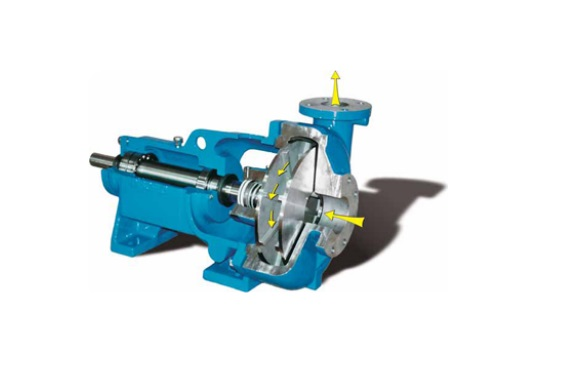

The Benefis of Seepex Range Pump

- Low-cost due to the removed bearing frame, flexible coupling and common base plate

- Easy maintenance due to the plug-in connection between the rotating unit and drive

- Separate pump bearing omitted

The Application of Seepex Range Pump

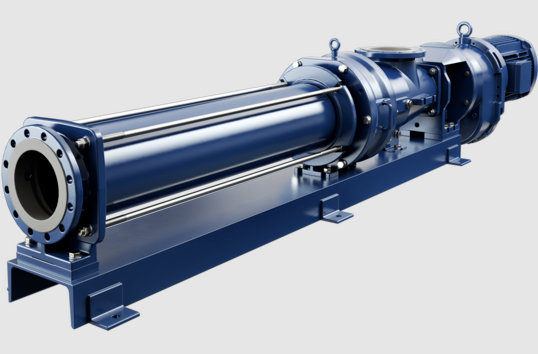

The Seepex Range Pump finds application in various industries due to its versatile capabilities. It is commonly used for efficient and reliable handling of viscous and abrasive fluids, including sludges, slurries, and pastes. With its progressive cavity design, the pump ensures consistent flow rates and gentle product handling, making it suitable for food processing, wastewater treatment, chemical manufacturing, and many other industrial applications.

The Spare Parts of Seepex Range Pump

Accessories

- Universal joint protection

- Dry-running protection device TSE

- Stator tensioning device

- Over-/underpressure protection device

- Metering device

Seal barrier system

- Shaft Seals

- SEEPEX gland packing (standard design)

- SEEPEX gland packing with grease chamber or seal cage

- SEEPEX double-acting mechanical seals

- SEEPEX cartridge mechanical seals

- SEEPEX single-acting mechanical seals

Send Your Enquiry :