-

-

Pump Screw-PMV Pump

People Also Ask

-

-

Type of Screw Pump-Pumpvv

What is a screw pump? Screw pump is a part of the dry compressed gas transfer pump series. They are positive displacement pumps that use one or more screws to move fluid or water along the screw shaft. These screws interlock to pressurize the fluid and move it into the system. These screws engage each…

-

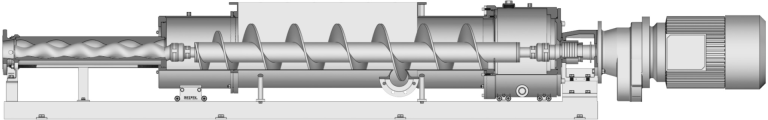

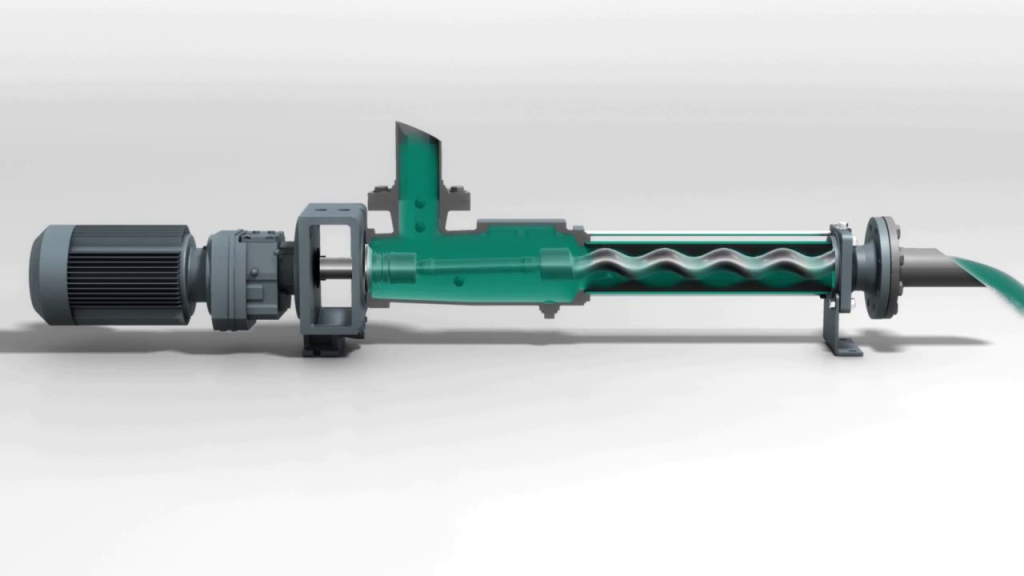

Screw Pump Diagram

Introduction to Screw Pump Diagram. A screw pump diagram is a schematic representation of the working principle and components of a screw pump. Screw pumps are positive displacement pumps that use rotating screws to move fluids or slurries through a system. They are widely used in various industries due to their ability to handle high…

-

Hygienic Twin Screw Pump

Hygienic Twin Screw Pump, More Commonly Known as Sanitary Twin Screw Pump. The hygienic twin screw pump is an advanced pumping solution designed for applications requiring high hygiene standards. It is generally know as a sanitary twin screw pump,and specifically developed to handle sensitive and viscous fluids in industries such as food and beverage, pharmaceuticals,…

-

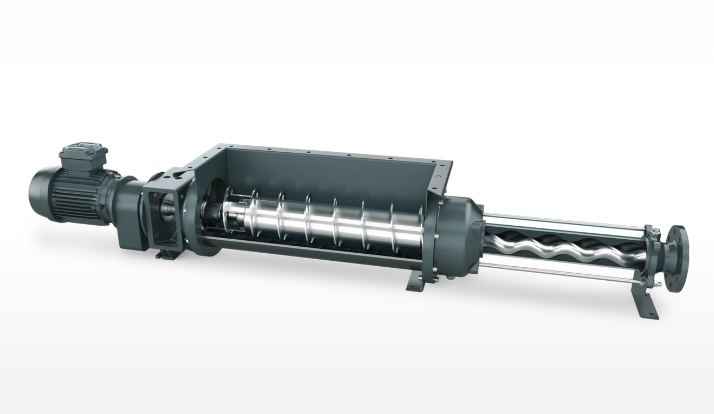

NETZSCH NEMO® BF Hopper Shaped Pump With Feed Screw

Efficient Handling of Viscous and Crumbly Substances The NEMO® BF Hopper Pump With Feed Screw is an effective solution for handling highly viscous and crumbly substances that do not tend to form bridges. Its design allows for efficient feeding and prevents clogging, ensuring a smooth and controlled material flow. With its robust construction and advanced…

-

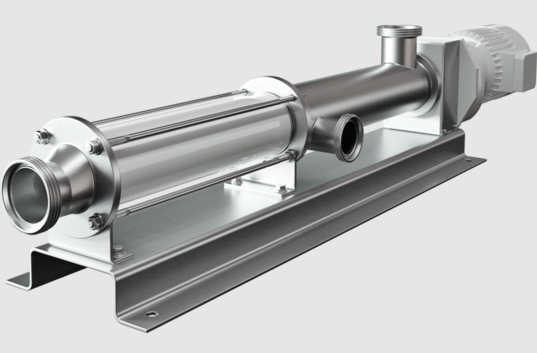

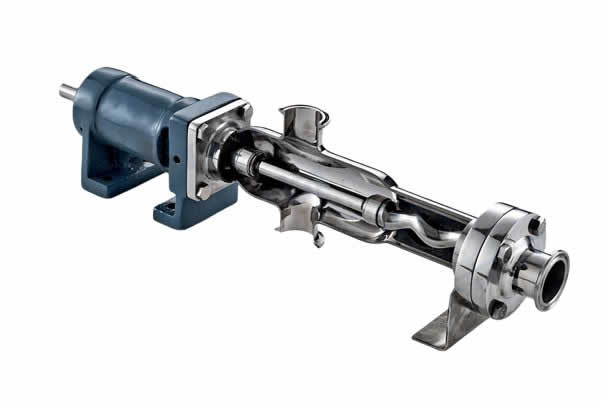

NETZSCH NOTOS® 2NSH Hygienic Twin Screw Pump

NETZSCH NOTOS® 2NSH Screw Pump NETZSCH NOTOS is made of AISI 316L stainless steel and polished according to international standards, making iteasy to clean (CIP) and to sterilize (SIP). As there is no contact between the rotating parts, the pump speedcan be increased. Therefore cleaning can be carried out without the need for an auxiliary…

-

Sludge Screw Pump

Sludge Screw Pump What is Sludge Screw Pump? Sludge screw pump that use one or several screws to move fluids or solids along the screw(s) axis. In its simplest form (the Archimedes’ screw pump), a single screw rotates in a cylindrical cavity, thereby moving the material along the screw’s spindle. The specific application of the…

-

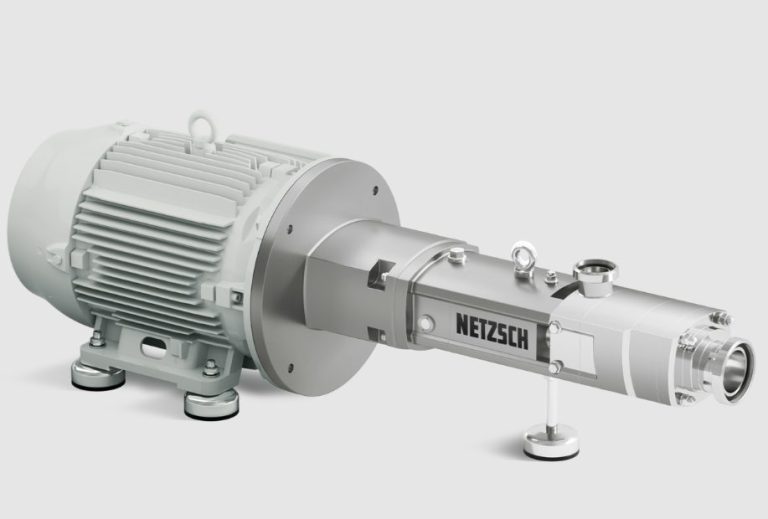

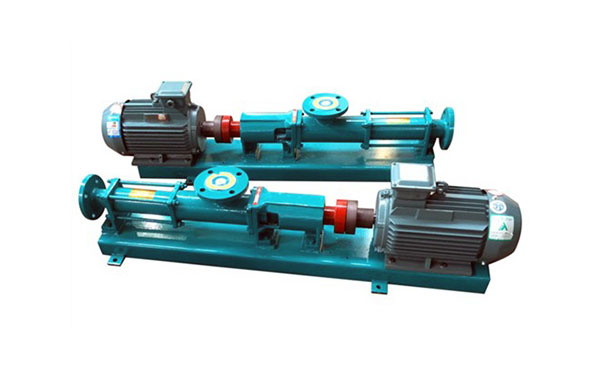

G Type Single Screw Pump

G Type Single Screw Pump Single Screw Pump Operating Principle and Benefits Single screw pump is a type of rotary positive displacement pump that operates based on the positive displacement principle. The pump works by creating sealed cavities through the interference fit of a single-helix metal rotor and a double-helix elastic stator. Due to the…

single screw type pump

Single screw pumps, also known as progressive cavity pumps or screw pumps, are positive displacement pumps that use a single screw mechanism to transport fluids. They are known for their ability to handle viscous fluids and are widely used in various industrial applications.

1. Key Features of Single Screw Pumps

-

- Single Screw Mechanism:

-

- Utilizes a helical screw that rotates within a cylindrical chamber, creating a series of cavities that move the fluid.

-

- Low Shear:

-

- Designed to minimize shear forces, making them suitable for sensitive or shear-sensitive fluids.

-

- Self-Priming:

-

- Capable of self-priming, allowing for easy startup without needing to fill the pump with liquid first.

-

- Versatile Design:

-

- Can be customized for various applications, including handling abrasive, corrosive, or viscous materials.

2. Applications of Single Screw Pumps

-

- Food and Beverage Industry:

-

- Ideal for transferring thick products like sauces, creams, and pastes without damaging the product.

-

- Chemical Processing:

-

- Used for pumping aggressive chemicals, polymers, and viscous fluids in chemical manufacturing.

-

- Pharmaceuticals:

-

- Suitable for precise dosing and handling of sensitive pharmaceutical products.

-

- Wastewater Treatment:

-

- Effective for pumping sludge and other viscous materials in wastewater management systems.

3. Advantages of Single Screw Pumps

-

- High Efficiency:

-

- Provides a steady flow rate with minimal pulsation, enhancing process efficiency.

-

- Gentle Handling:

-

- The design ensures gentle handling of fluids, preserving the integrity of the product.

-

- Durable Construction:

-

- Built with robust materials to withstand harsh operating conditions.

-

- Easy Maintenance:

-

- Designed for straightforward maintenance, reducing downtime and operational costs.

4. Considerations When Choosing Single Screw Pumps

-

- Fluid Characteristics:

-

- Understand the viscosity, temperature, and chemical properties of the fluid to ensure compatibility.

-

- Flow Rate Requirements:

-

- Determine the necessary flow rate to select the appropriate pump size and configuration.

-

- Operating Environment:

-

- Consider the installation location and environmental factors that may impact pump performance.