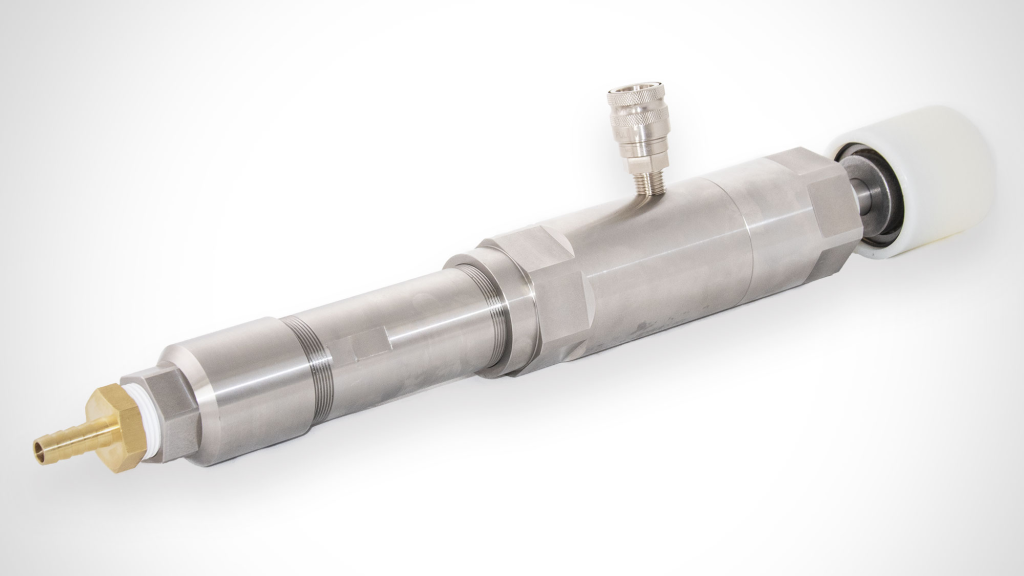

Small Progressive Cavity Pump-PMV PUMP

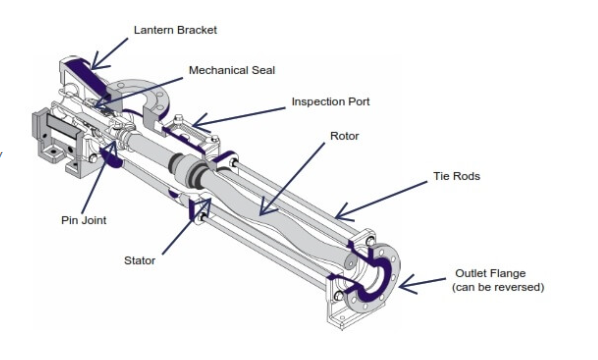

Progressive cavity pumps are part of the positive displacement pump family. Each of the positive displacement pumps we have covered in the previous Quick and Dirty Guides (external gear, internal gear, rotary lobe, peristaltic, and diaphragm) have unique designs and capabilities. The progressive cavity pump is no different. What is a progressive cavity pump? Progressive…