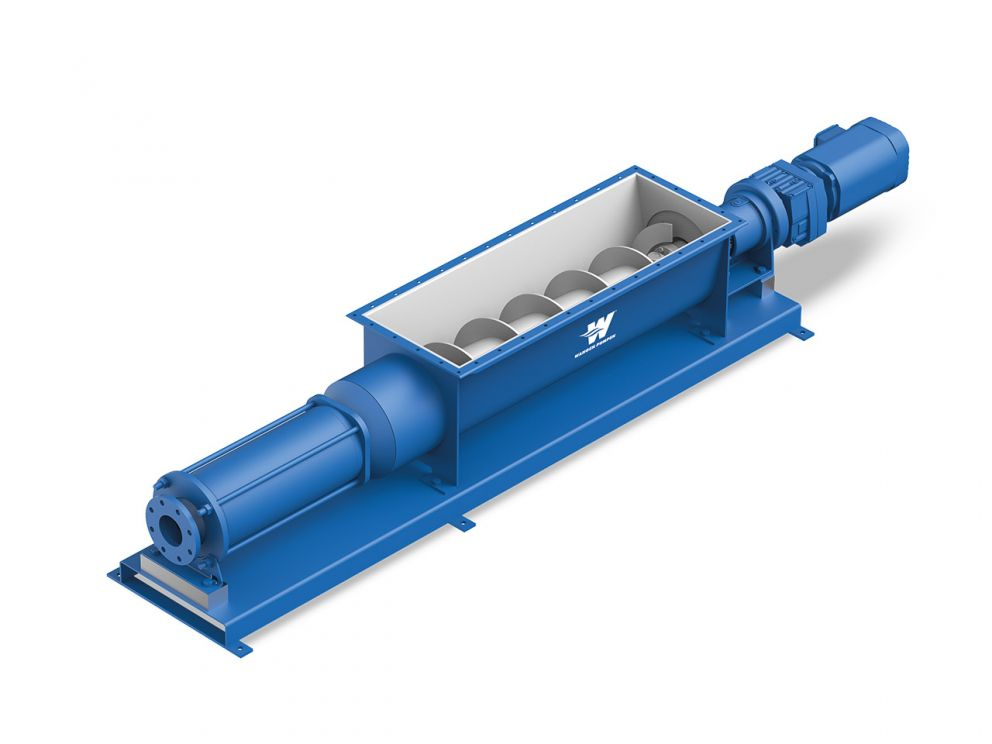

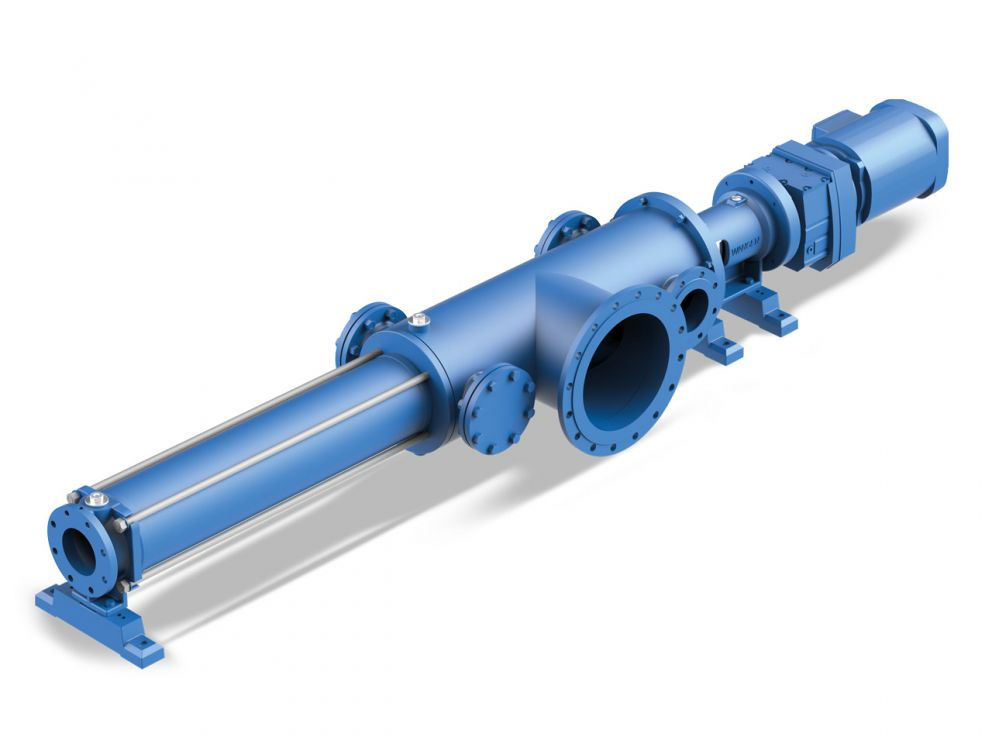

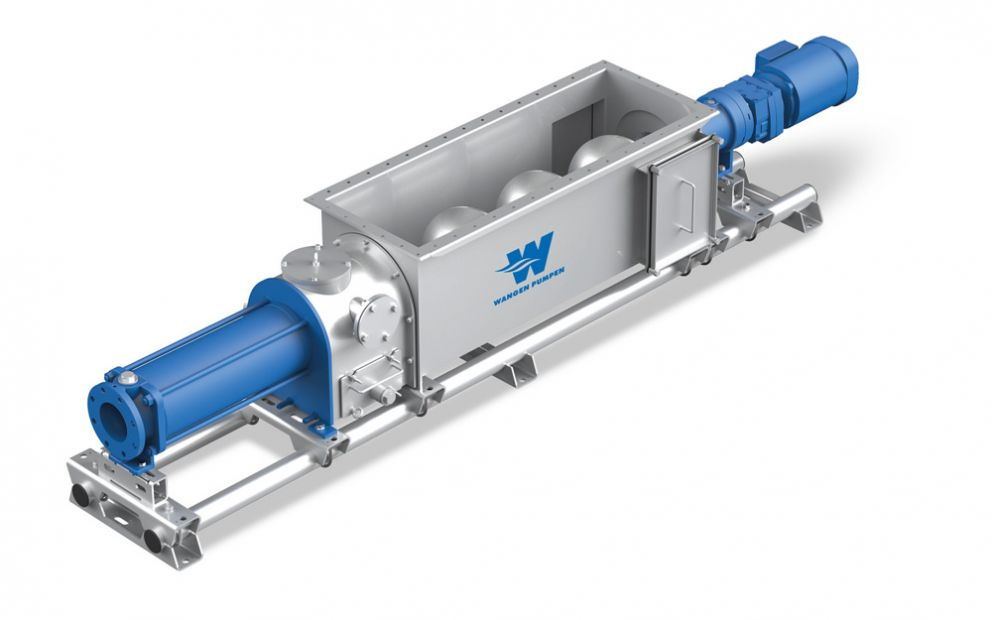

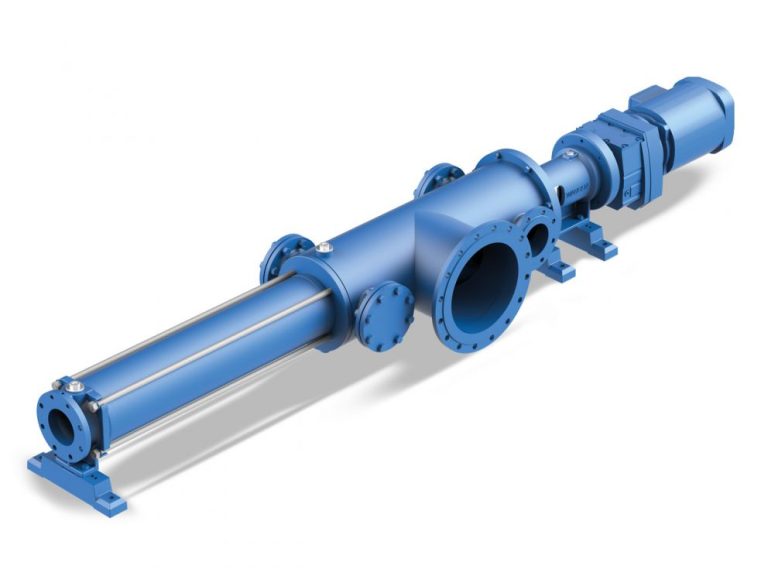

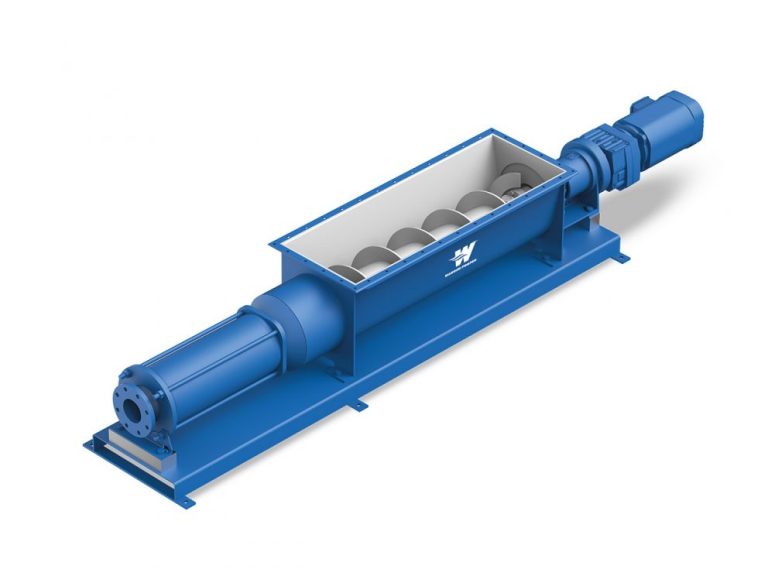

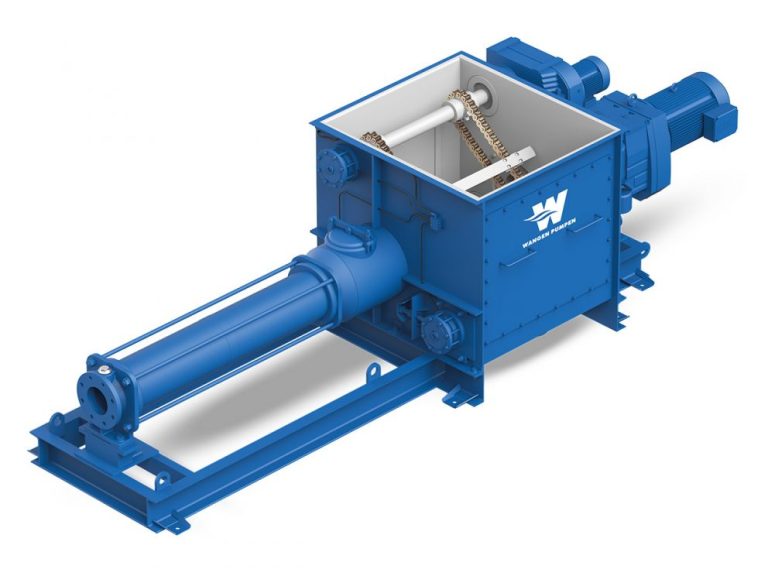

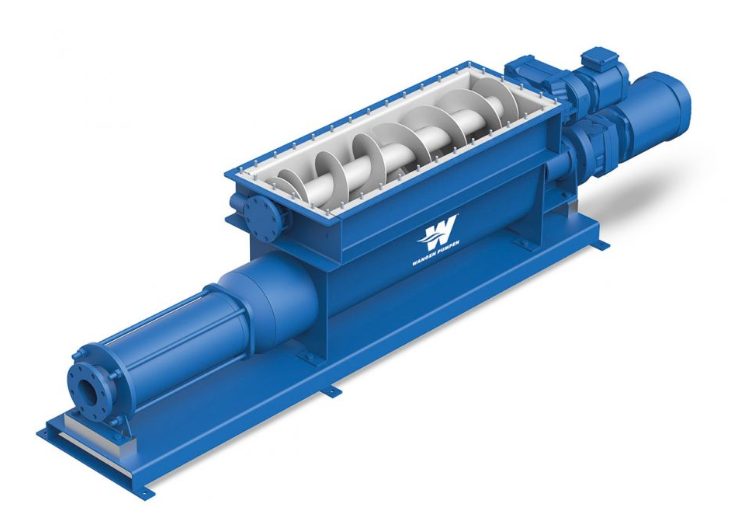

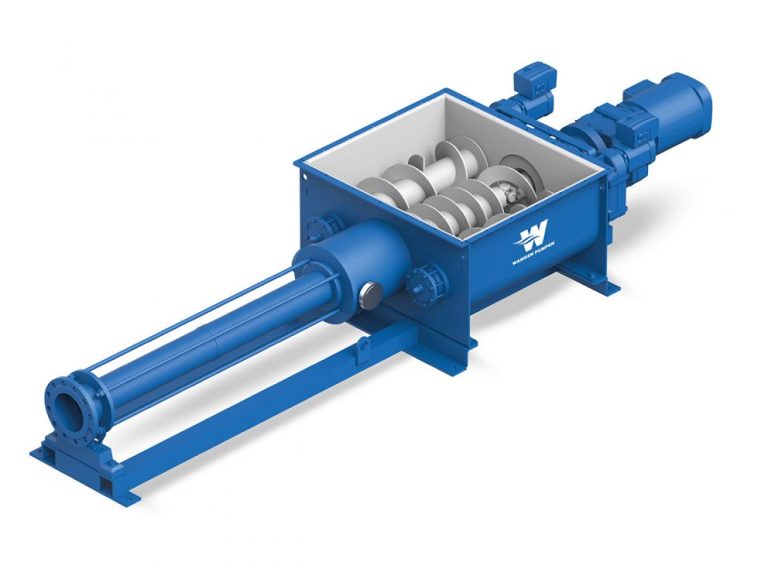

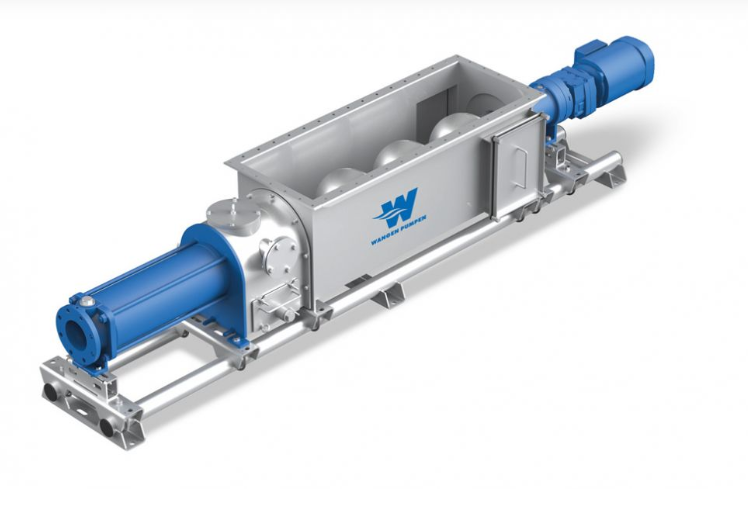

WANGEN Type BIO-FEED Self-priming Pump

WANGEN BIO-FEED with X-LIFT quick-change system Flexible and cost-efficient WANGEN PUMPEN’s newly-developed WANGEN BIO-FEED is designed especially for machines that would like to combine existing screw technology at the substrate storage container with the feeding of liquids. People Also Ask