Introduction

In the field of fluid transportation, selecting the right pump is crucial. The Bellin progressive cavity pump, known for its unique design and exceptional performance, has become a preferred choice in various industries. This article will explore the working principle, advantages, and wide range of applications of the Bellin progressive cavity pump.

Working Principle

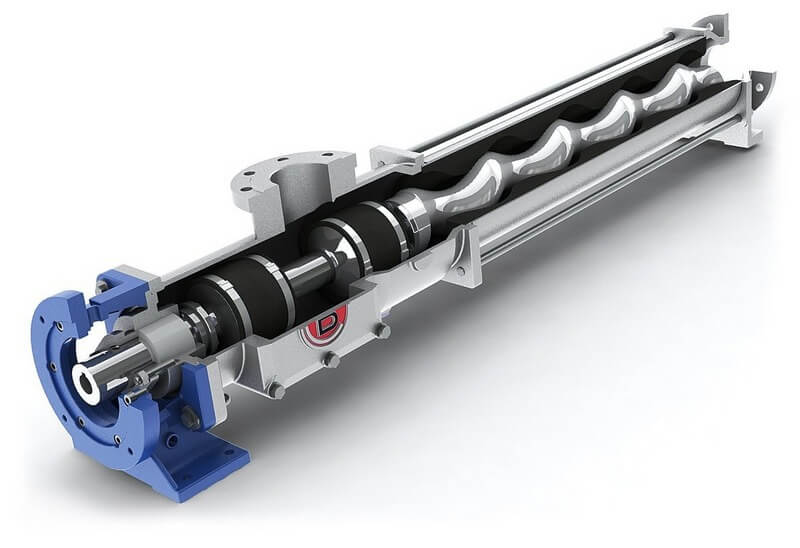

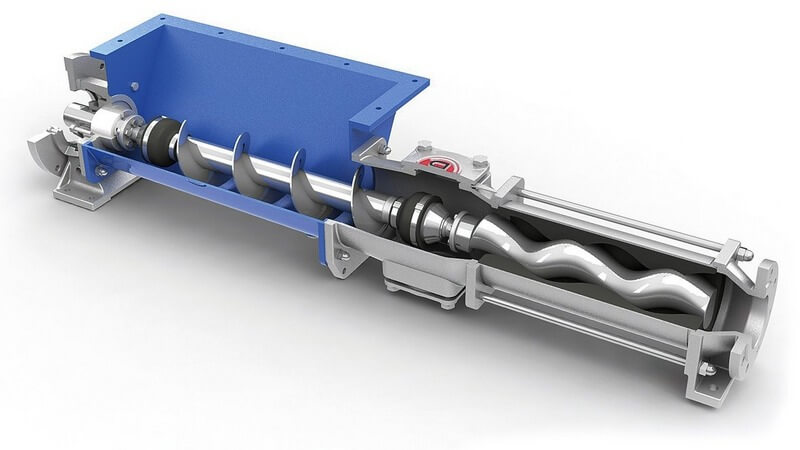

The Bellin progressive cavity pump is a type of positive displacement pump, featuring a pair of intermeshing screws as its core components. The working principle of this pump is both simple and efficient:

- Inlet: Fluid enters the pump chamber through the inlet.

- Transport: The rotation of the screws moves the fluid forward along the pump chamber.

- Discharge: The fluid is discharged through the outlet to the target location.

This design enables the pump to smoothly transport fluids of varying viscosities without generating bubbles or shear forces.

Advantages of Bellin Progressive Cavity Pump

The design of the Bellin progressive cavity pump offers several significant advantages:

- Efficiency: The structure ensures continuous fluid transport, minimizing energy loss.

- Versatility: Capable of handling a variety of fluids, including those with high viscosity and particulate matter.

- Low Shear Force: Ideal for transporting shear-sensitive liquids, such as emulsions and suspensions.

- Ease of Maintenance: The design allows for simple component replacement and maintenance, reducing downtime.

- Durability: Constructed from high-quality materials, it offers excellent corrosion and wear resistance, extending its lifespan.

Applications

The Bellin progressive cavity pump is widely used across multiple industries. Here are some key application areas:

- Chemical Industry: Used for transporting chemical raw materials and intermediates, handling corrosive and high-viscosity substances.

- Food and Beverage: Suitable for transferring syrups, dairy products, and other liquid food items, meeting hygiene standards.

- Oil and Gas: Employed in oil fields and refineries for transporting crude oil and its derivatives.

- Water Treatment: Utilized in the treatment and transportation of wastewater, contributing to environmental protection.

- Pharmaceutical Industry: Pumps drugs and chemical reagents, ensuring product safety and efficacy.

Conclusion

The Bellin progressive cavity pump, with its unique design and outstanding performance, provides invaluable solutions in various fluid transport applications. Whether handling high-viscosity fluids or transporting shear-sensitive materials, the Bellin progressive cavity pump ensures efficient and reliable operation. With ongoing technological advancements, its application scope is expected to expand further, contributing significantly to the development of various industries.

People also ask

Send Your Enquiry :