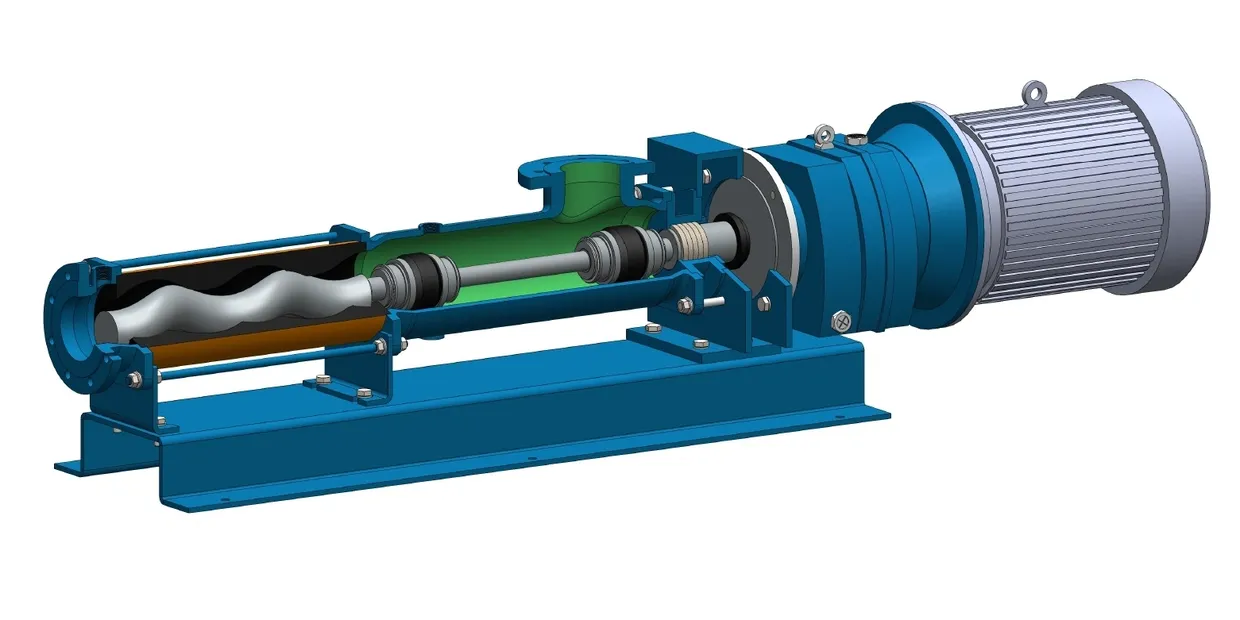

Disadvantages of Progressive Cavity Pumps

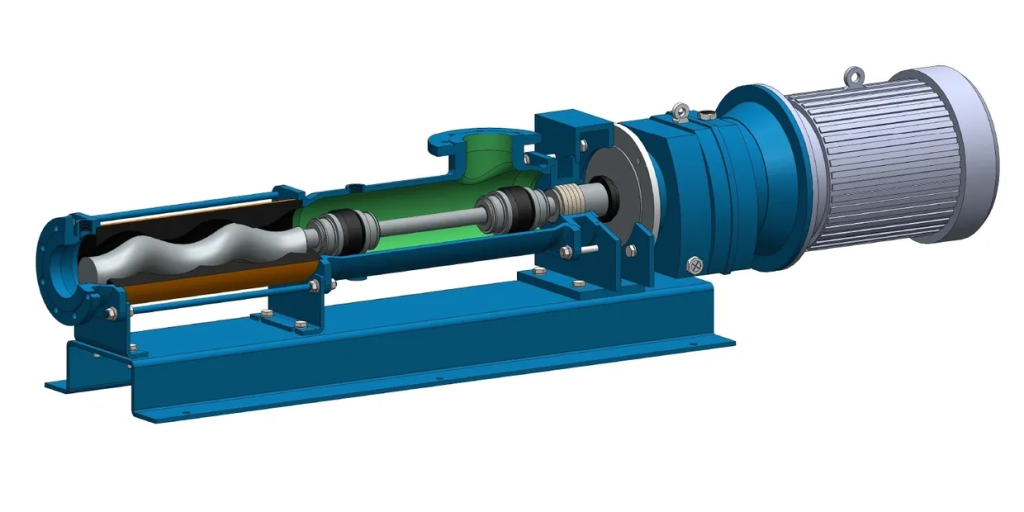

Progressive cavity pumps (PCPs) are widely used for various applications due to their ability to handle viscous fluids and provide a steady flow. However, despite their advantages, there are several disadvantages associated with these pumps that should be considered before their implementation. This article explores some of the primary drawbacks of progressive cavity pumps.

1. High Initial Cost

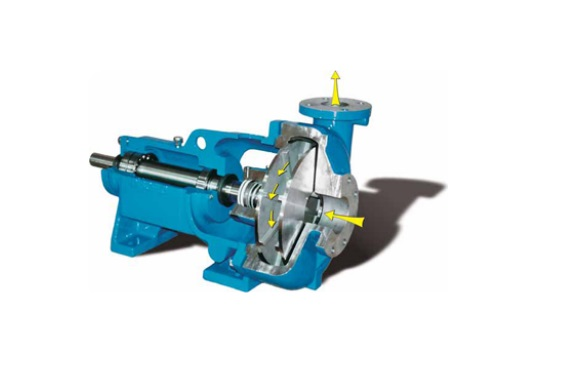

One of the most significant disadvantages of progressive cavity pumps is their high initial cost. The complexity of their design and the materials used in manufacturing contribute to this expense. Compared to other types of pumps, such as centrifugal pumps, the initial investment for a PCP can be considerably higher, making them less appealing for budget-conscious projects.

2. Maintenance Requirements

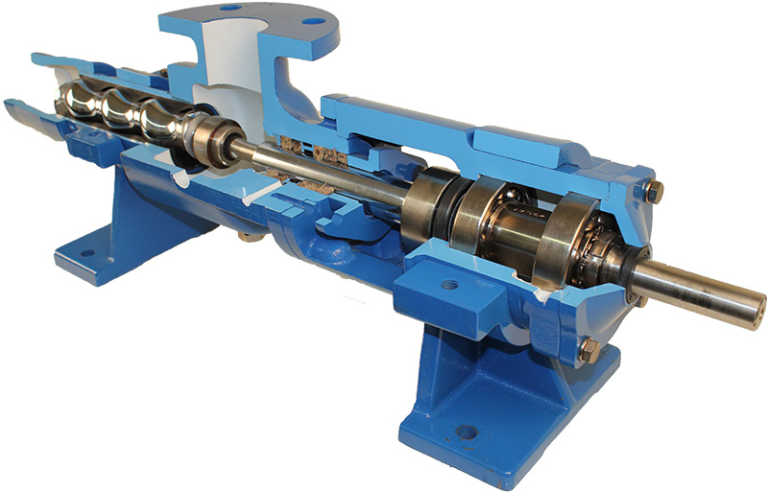

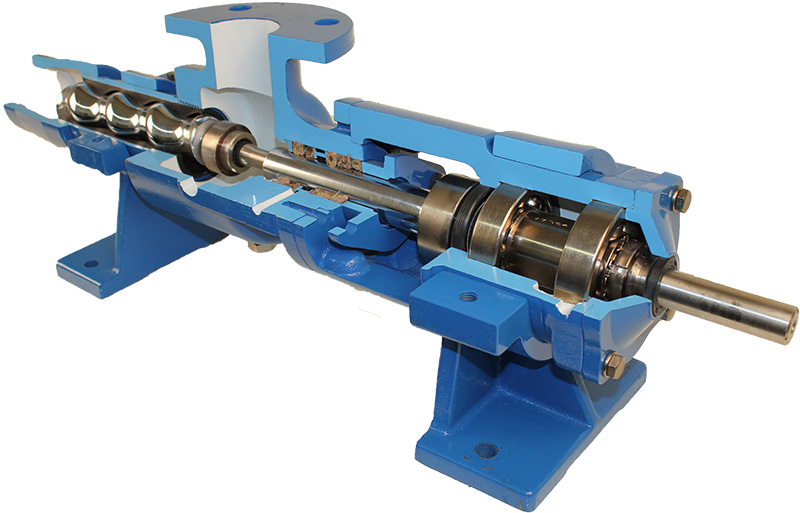

Progressive cavity pumps require regular maintenance to ensure optimal performance. The rotor and stator components are subject to wear and tear over time, which necessitates frequent inspections and replacements. This maintenance can be costly and time-consuming, potentially leading to extended downtime. In industries where continuous operation is critical, this can pose a significant challenge.

3. Limited Operating Range

While PCPs are known for their ability to handle viscous fluids, they have a limited operating range in terms of flow rates and pressures. They may not be suitable for applications that require variable flow conditions or high pressure. This limitation can restrict their use in certain industrial settings where flexibility is essential.

4. Sensitivity to Fluid Characteristics

Progressive cavity pumps can be sensitive to the characteristics of the fluids they are handling. Changes in viscosity, temperature, or the presence of solids can affect the pump’s efficiency and performance. If the fluid properties vary significantly, it may lead to operational issues, such as reduced flow rates or increased wear on the pump components.

5. Noise and Vibration

Another disadvantage of progressive cavity pumps is the noise and vibration they can generate during operation. This can be particularly problematic in environments where quiet operation is necessary. The mechanical action of the pump can lead to vibrations that may affect nearby equipment or structures, requiring additional measures to mitigate these effects.

6. Installation Complexity

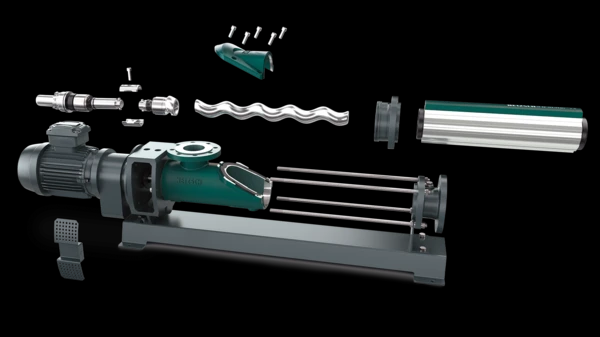

The installation of progressive cavity pumps can be more complex compared to other pumping systems. They often require precise alignment and specific mounting arrangements to operate effectively. This complexity can lead to increased installation costs and may necessitate specialized skills or training for personnel involved in the setup.

Conclusion

While progressive cavity pumps offer unique advantages for certain applications, their disadvantages cannot be overlooked. The high initial cost, maintenance requirements, limited operating range, sensitivity to fluid characteristics, noise and vibration issues, and installation complexity are all factors that should be carefully considered. Before selecting a pump for a specific application, it is essential to weigh these drawbacks against the potential benefits to ensure an informed decision.

Send Your Enquiry :