[wpseo_breadcrumb]

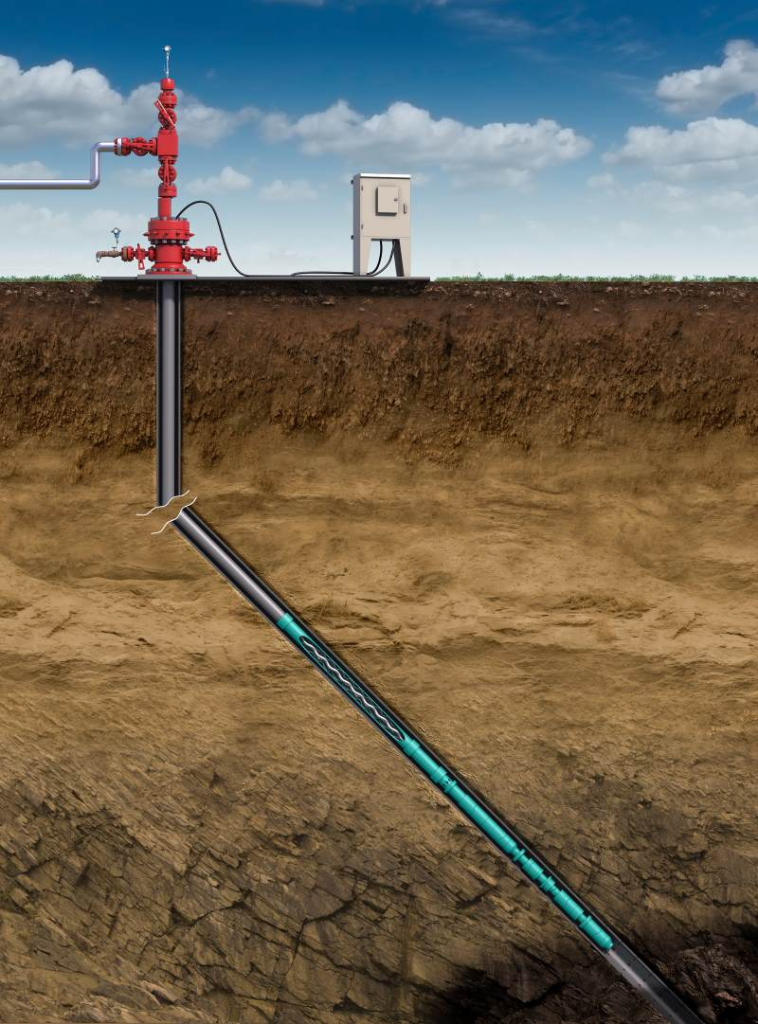

Downhole cavity pumps are essential components in the oil and gas industry, designed to efficiently extract fluids from subterranean reservoirs. These pumps are particularly valuable in challenging environments, where traditional pumping methods may fail to perform optimally. This article explores the working principles, advantages, and applications of downhole cavity pumps.

Working Principles

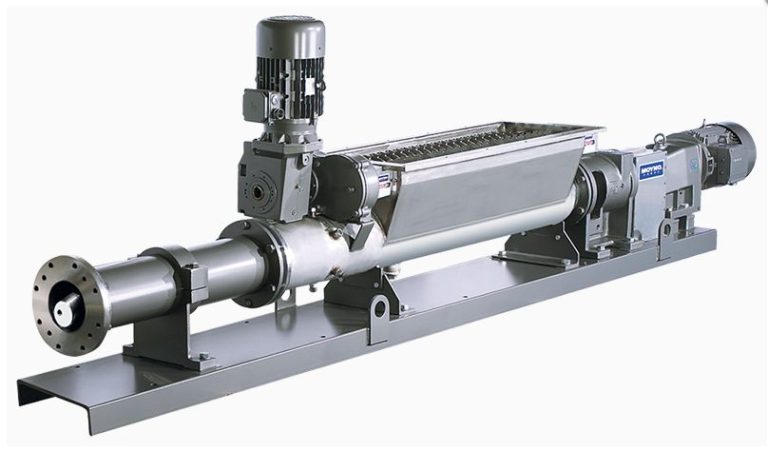

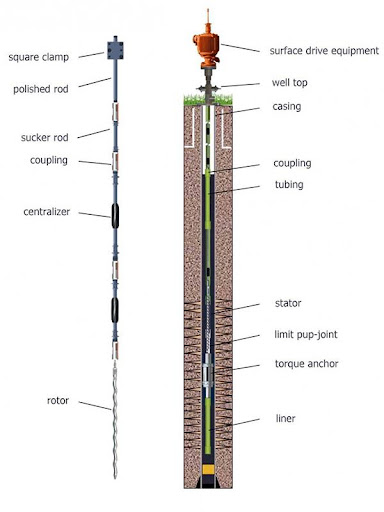

Downhole cavity pumps function based on a simple yet effective mechanism. They consist of a rotor and a stator, which create cavities that trap and transport fluids upward. Here’s a breakdown of the key components:

- Rotor: The rotating element that creates a series of cavities as it spins within the stator.

- Stator: The stationary part that surrounds the rotor, designed to match its shape and allow for fluid movement.

- Cavities: Spaces formed between the rotor and stator that hold and move the fluid.

As the rotor turns, it continuously generates new cavities that draw in fluid from the well. This action creates a pressure differential, allowing the fluid to flow upward through the wellbore.

Advantages of Downhole Cavity Pumps

Downhole cavity pumps offer several advantages over other pumping solutions. These include:

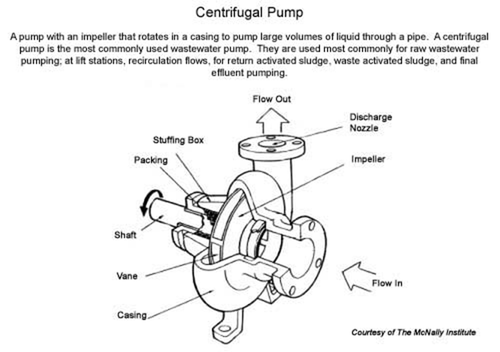

- High Efficiency: The design minimizes fluid turbulence, allowing for smoother and more efficient fluid flow.

- Versatility: Suitable for various fluid types, including oil, gas, and water, making them adaptable for different applications.

- Reliability: Fewer moving parts reduce the likelihood of mechanical failure, resulting in lower maintenance costs.

- Reduced Energy Consumption: The efficient fluid handling reduces the overall energy required for operation, leading to cost savings.

Applications

The versatility of downhole cavity pumps makes them suitable for a range of applications, including:

- Oil Extraction: Essential for extracting crude oil from deep reservoirs, especially in areas with high viscosity.

- Water Injection: Used in enhanced oil recovery techniques by injecting water into reservoirs to maintain pressure.

- Geothermal Energy: They can also be utilized in geothermal wells to extract hot water or steam for energy production.

- Wastewater Management: Effective in pumping wastewater from industrial processes or municipal systems.

Conclusion

Downhole cavity pumps play a critical role in modern extraction techniques, enhancing efficiency and reliability in fluid transportation from deep reservoirs. Their unique design and operational principles allow them to excel in challenging environments, making them a preferred choice in the oil and gas industry, as well as in other fluid management applications. As technology advances, the role of downhole cavity pumps is likely to expand, further contributing to resource extraction and environmental management.

Send Your Enquiry :