Introduction

Progressive cavity pumps are widely recognized for their ability to handle various fluids, including those with high viscosities and solids. However, one of the critical factors affecting their performance is the Net Positive Suction Head (NPSH). A low NPSH progressive cavity pump addresses specific challenges in applications where traditional pumps may struggle.

Understanding NPSH

NPSH is a crucial parameter in pump engineering, representing the pressure available at the pump inlet to prevent cavitation. Cavitation can lead to significant damage and decreased efficiency. Low NPSH pumps are specially designed to operate effectively in conditions where the NPSH available is limited.

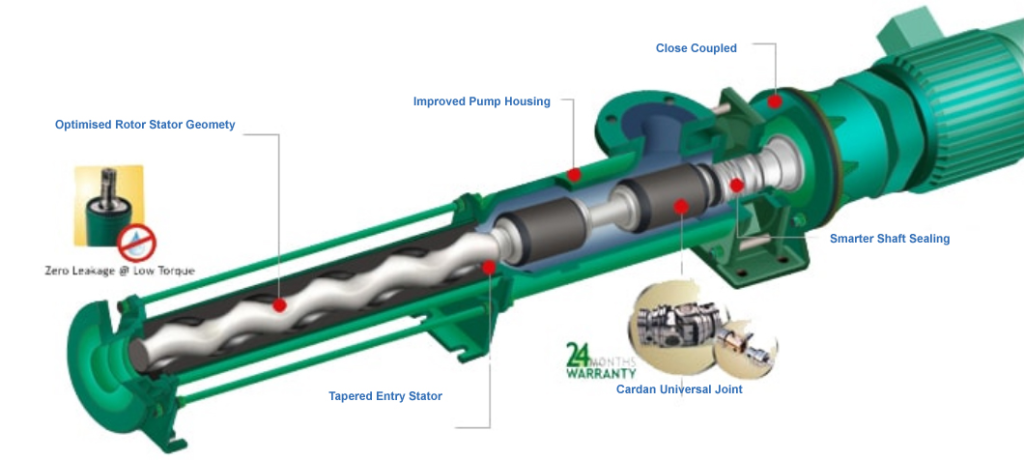

Characteristics of Low NPSH Progressive Cavity Pumps

Low NPSH progressive cavity pumps possess several unique characteristics that make them suitable for specific applications:

- Cavitation Resistance: Designed to minimize the risk of cavitation, these pumps maintain smooth and continuous flow, even with limited suction pressure.

- Versatile Applications: They can be used in various industries, including wastewater treatment, food processing, and chemical handling, where low suction conditions are common.

- Self-Priming Capability: Many low NPSH models are self-priming, allowing them to start pumping without the need for external priming equipment.

- Durability: Constructed with robust materials, these pumps can handle abrasive and viscous fluids, extending their lifespan and reducing maintenance costs.

Advantages of Low NPSH Progressive Cavity Pumps

Utilizing low NPSH progressive cavity pumps offers several advantages:

- Efficiency: They operate efficiently under low suction conditions, ensuring consistent flow rates and reduced energy consumption.

- Reduced Cavitation Risk: With their design, these pumps significantly lower the chances of cavitation-related damage, leading to fewer operational issues.

- Versatility: Their ability to handle a wide range of fluids makes them adaptable to various industrial processes, enhancing operational flexibility.

- Lower Maintenance Needs: The robust design and cavitation resistance lead to fewer breakdowns, resulting in lower maintenance requirements and costs.

Applications

Low NPSH progressive cavity pumps find their place in numerous applications, such as:

- Wastewater Treatment: Effectively handling sludge and other challenging materials in treatment plants.

- Food Industry: Ensuring safe and efficient transfer of food products, including those with particulates.

- Chemical Processing: Managing corrosive or viscous fluids with precision and reliability.

Conclusion

Low NPSH progressive cavity pumps are essential tools in various industries, offering unique solutions for handling fluids under challenging conditions. Their ability to operate efficiently with low suction pressure, combined with their durability and versatility, makes them a preferred choice for many applications. Understanding their characteristics and advantages can help industries optimize their fluid handling processes while minimizing operational risks.

People also ask

Send Your Enquiry :