Progressive cavity pumps are widely used in various industries due to their ability to handle viscous and shear-sensitive fluids. Understanding the Net Positive Suction Head (NPSH) required for these pumps is crucial for ensuring optimal performance and preventing operational issues. This article explores the importance of NPSH, its implications for pump operation, and best practices for ensuring adequate NPSH.

Understanding NPSH

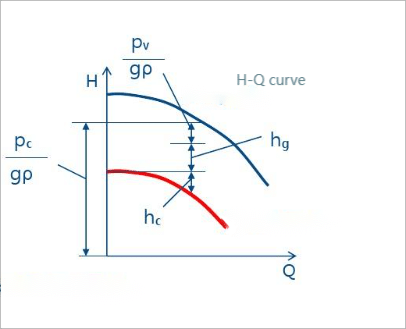

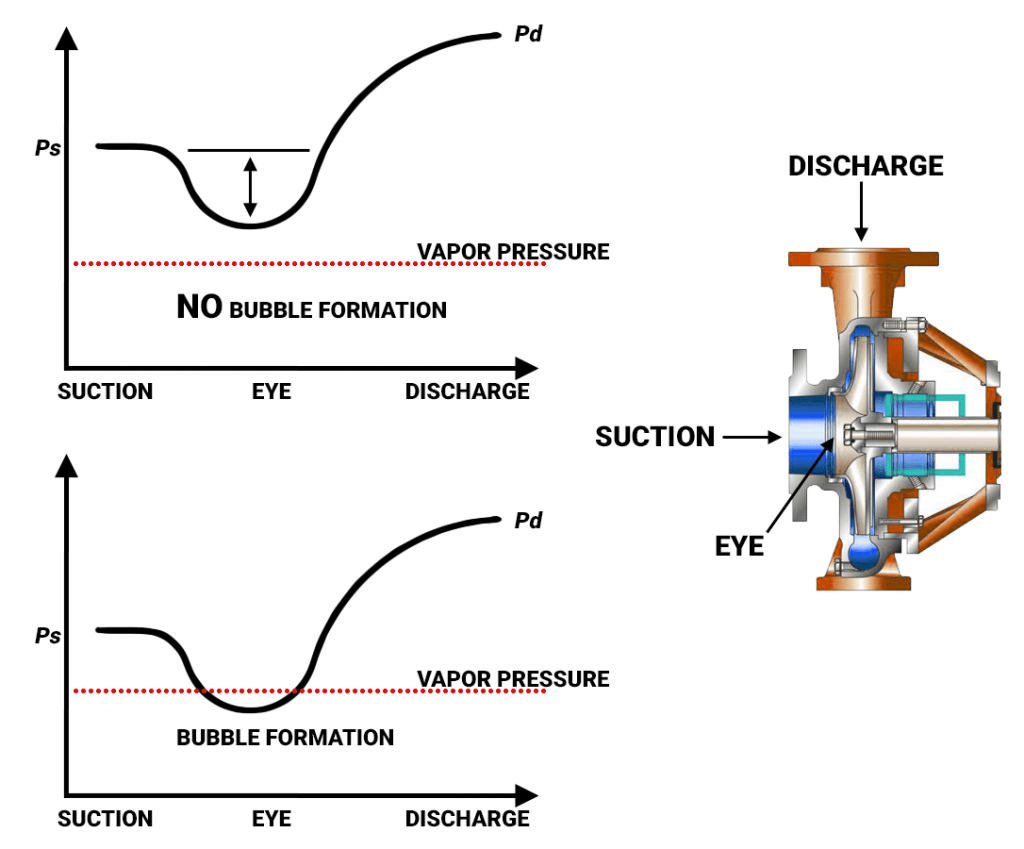

NPSH stands for Net Positive Suction Head, which is a measure of the pressure available at the pump inlet to prevent cavitation. In the context of progressive cavity pumps, NPSH is vital as it directly influences the pump’s efficiency and longevity. Cavitation can lead to severe damage, resulting in costly repairs and downtime.

Components of NPSH

- Static Head: The vertical distance from the fluid surface to the pump inlet.

- Velocity Head: The kinetic energy of the fluid as it enters the pump.

- Friction Losses: Losses due to the resistance of fluid flow through pipes and fittings.

For progressive cavity pumps, maintaining an adequate NPSH is essential to ensure that the pump operates smoothly without the risk of cavitation.

Importance of NPSH in Progressive Cavity Pumps

The NPSH required for a progressive cavity pump is determined by its design and the characteristics of the fluid being pumped. Here are some key reasons why NPSH is important:

- Prevention of Cavitation: Adequate NPSH prevents the formation of vapor bubbles, which can collapse violently and cause damage to the pump components.

- Operational Efficiency: Sufficient NPSH ensures that the pump operates at its designed capacity, minimizing energy consumption and maximizing output.

- Longevity of Equipment: Maintaining proper NPSH reduces wear and tear on the pump, extending its operational life.

Best Practices for Ensuring Adequate NPSH

To ensure that the progressive cavity pump operates effectively, consider the following best practices:

- Correct Installation: Ensure that the pump is installed at the correct height relative to the fluid source to maximize static head.

- Minimize Friction Losses: Use smooth and appropriately sized pipes to reduce friction losses, enhancing the NPSH available at the pump inlet.

- Monitor Fluid Temperature: Be aware that temperature affects fluid density and viscosity. Adjust the system accordingly to maintain optimal NPSH.

- Regular Maintenance: Conduct routine inspections and maintenance to identify and rectify issues that could impact NPSH.

Conclusion

The NPSH required for progressive cavity pumps is a critical factor in ensuring efficient and reliable pump operation. By understanding and managing the components of NPSH, operators can prevent cavitation, enhance operational efficiency, and prolong the life of their equipment. Implementing best practices in installation, maintenance, and monitoring can significantly contribute to the successful operation of progressive cavity pumps in various applications.

People also ask

Send Your Enquiry :