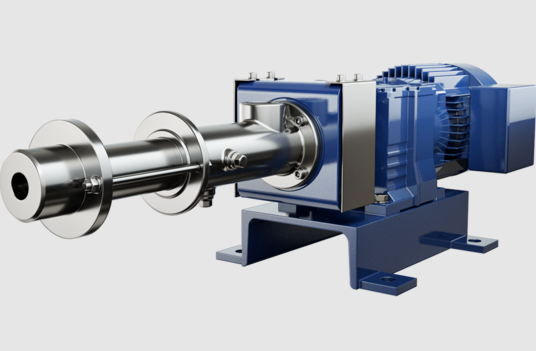

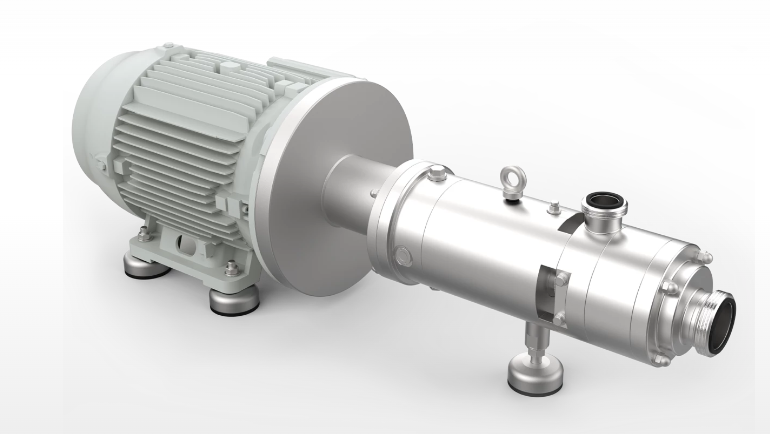

Hygienic Twin Screw Pump, More Commonly Known as Sanitary Twin Screw Pump.

The hygienic twin screw pump is an advanced pumping solution designed for applications requiring high hygiene standards. It is generally know as a sanitary twin screw pump,and specifically developed to handle sensitive and viscous fluids in industries such as food and beverage, pharmaceuticals, and personal care. With its innovative design and features, this pump offers exceptional performance and reliability in demanding hygienic environments.

The Description of Hygienic Twin Screw Pump.

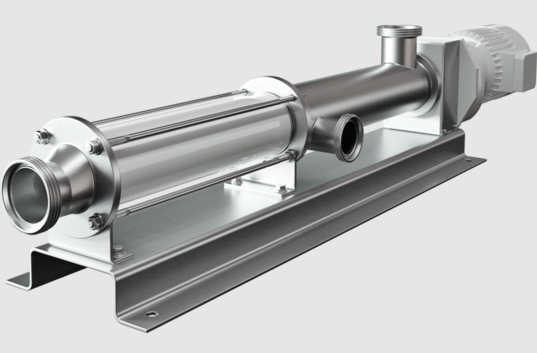

The Hygienic Twin Screw Pump utilizes a twin screw rotor configuration to create a smooth and continuous flow of fluids. The screws interlock and rotate within a tightly sealed chamber, minimizing pulsations and ensuring gentle product handling. The pump is constructed using high-quality stainless steel or other food-grade materials, ensuring compliance with stringent hygiene regulations.

The Applications of Hygienic Twin Screw Pump.

The Hygienic Twin Screw Pump finds extensive use in various applications across different industries. It is ideal for transferring sensitive and viscous fluids such as creams, gels, pastes, syrups, and emulsions. The pump is commonly employed in food and beverage production, where it handles ingredients like chocolate, sauces, dairy products, and beverages. In the pharmaceutical industry, it is used for transferring medicinal syrups, ointments, and creams. Additionally, it is utilized in the personal care industry for handling cosmetic creams, lotions, and shampoos.

The Features of Hygienic Twin Screw Pump

- Hygienic Design: The pump features a sanitary design, ensuring easy cleaning and preventing bacterial growth. It meets strict hygienic standards, including FDA and EHEDG guidelines.

- Gentle Product Handling: The twin screw configuration ensures gentle and shear-sensitive product handling, preserving the integrity and quality of the fluids being pumped.

- CIP/SIP Capabilities: The pump is designed for easy cleaning-in-place (CIP) and sterilization-in-place (SIP) processes, reducing downtime and ensuring maximum hygiene.

- High Efficiency: The twin screw design allows for a higher flow rate and improved efficiency, resulting in cost savings and reduced energy consumption.

- Versatility: The pump can handle a wide range of viscosities, from thin liquids to highly viscous fluids, providing versatility for different applications.

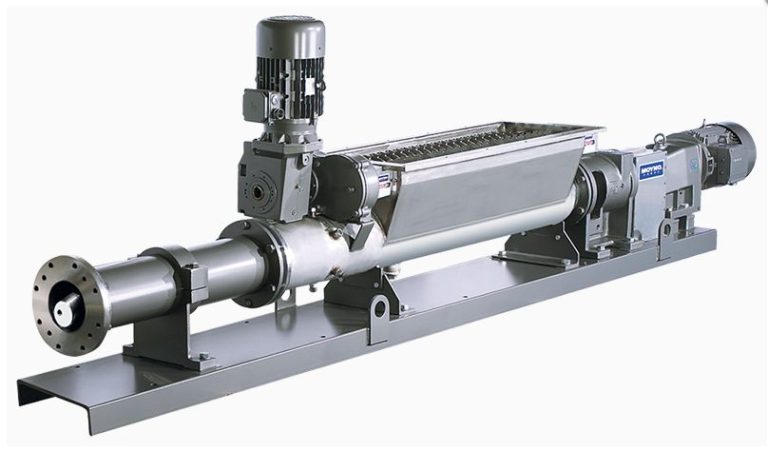

Comparison to SEEPEX BCSO and Netzsch Pump

While the sanitary twin screw pumps share similarities with SEEPEX BCSO and Netzsch Pump in terms of being used in hygienic applications, each pump has its own distinct features and advantages.

SEEPEx BCSO: SEEPEX BCSO is a progressive cavity pump that is also suitable for hygienic applications. It operates using a rotating rotor within a stator to create a pumping action. However, the Hygienic Twin Screw Pump offers advantages such as higher efficiency, easier cleaning, and greater versatility in handling various viscosities.

Netzsch Pump: Netzsch Pump is known for its progressive cavity pump technology, which also finds applications in hygienic environments. However, the Hygienic Twin Screw Pump stands out with its twin screw design, providing improved efficiency, higher flow rates, and better handling of shear-sensitive fluids.

In summary, the Hygienic Twin Screw Pump is a state-of-the-art pumping solution designed for hygienic applications. Its unique twin screw design, hygienic features, and versatility make it an ideal choice for industries that require efficient and reliable fluid transfer while maintaining high hygiene standards.

People Also Ask

Send Your Enquiry :