[wpseo_breadcrumb]

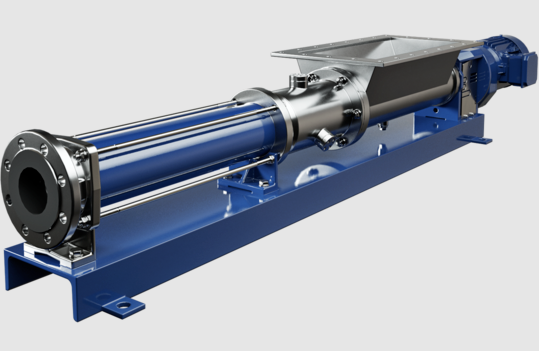

How to choose the right Seepex BN100-6L Stator?

When choosing the right BN100-6L stator, the following factors should be considered:

- Fluid properties: Understand the viscosity, solid content and other properties of the fluid to be processed in order to choose the right stator.

- Operating conditions: Including temperature, pressure, etc., which will affect the choice of stator.

- Maintenance management: Consider the company’s maintenance capabilities and the maintenance process of the equipment, and choose a model that is easy to maintain.

- Economical efficiency: Long-term energy consumption and maintenance costs should also be taken into consideration to improve the overall economic benefits.

Features of Seepex BN100-6L Stator

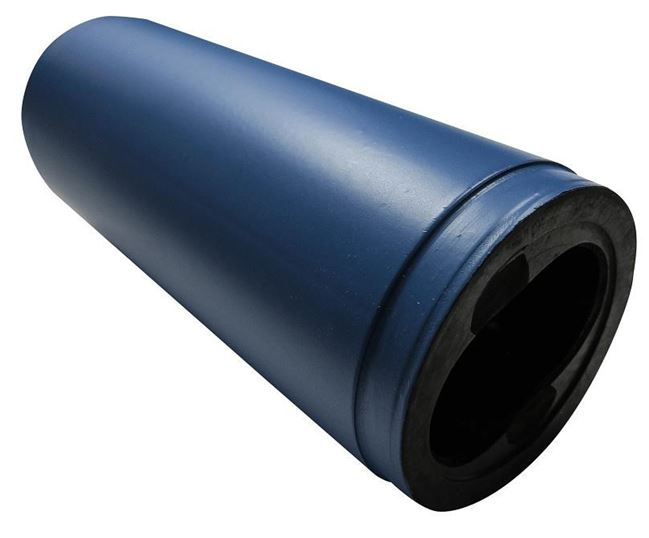

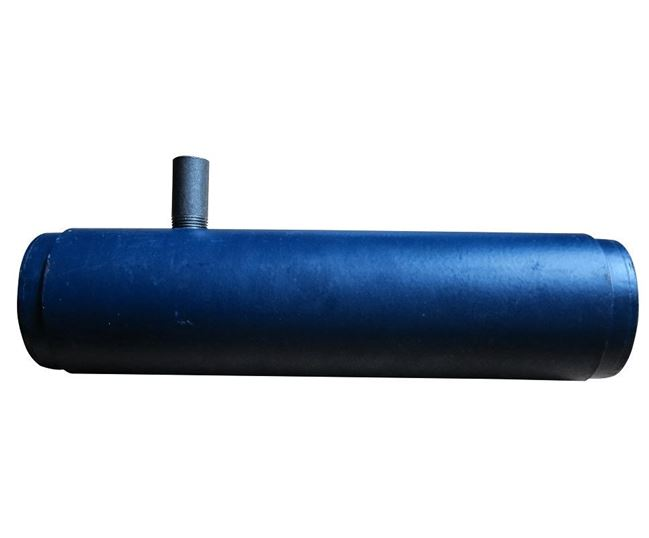

Material: Seepex BN100-6L Stator usually uses high-quality synthetic rubber material, which is not only wear-resistant, but also resistant to corrosion by a variety of chemicals and is suitable for various industrial environments.

Size and adaptability: The design of the stator of this model is precisely calculated to ensure a perfect match with the pump body and screw. This precise fit helps to improve the efficiency of the pump and reduce energy consumption.

High temperature resistance: In many applications, the fluids being processed may reach high temperatures. The Seepex BN100-6L Stator is specially designed to maintain stable performance in high temperature environments.

Application areas of the Seepex BN100-6L Stator

Industries that have witnessed the superior performance of the Seepex BN100-6L stator cover a wide range of fields:

Food and beverage:

In the food processing industry, when handling colloidal or viscous fluids, the BN100-6L can maintain efficient flow and ensure product quality.

Chemical oil products:

For oil products with higher viscosity, the use of the BN100-6L stator can reduce pump power consumption and improve production efficiency.

Environmental sewage treatment:

In the sewage treatment industry, when treating sewage containing solid matter, the stator shows excellent adaptability and durability.

Pharmaceutical industry:

In the pharmaceutical industry, the cleanliness and fluidity of the fluid are very high, and the Seepex BN100-6L stator can meet strict industrial standards.

people also ask

Send Your Enquiry :