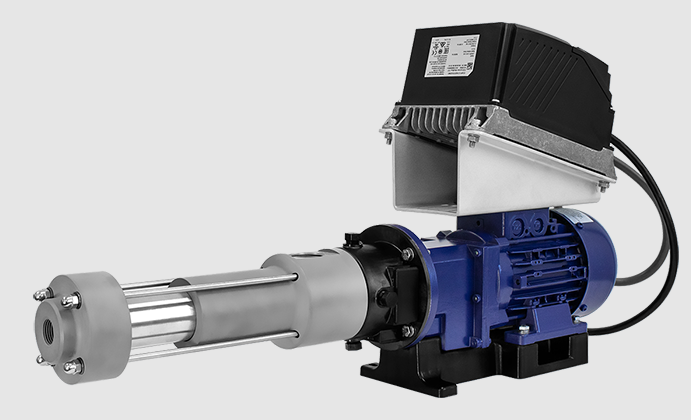

BN5-12L rotor seepex

seepex is a world-renowned pump equipment manufacturer, and its products are widely used in industrial production, sewage treatment, food manufacturing and other fields. Among them, the seepex BN5-12L rotor, as a product of the company, enjoys a good reputation in the industry for its excellent performance and reliability.

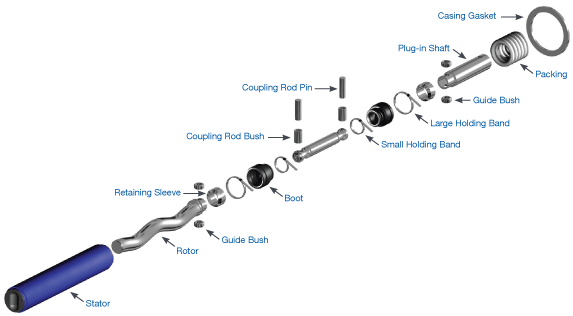

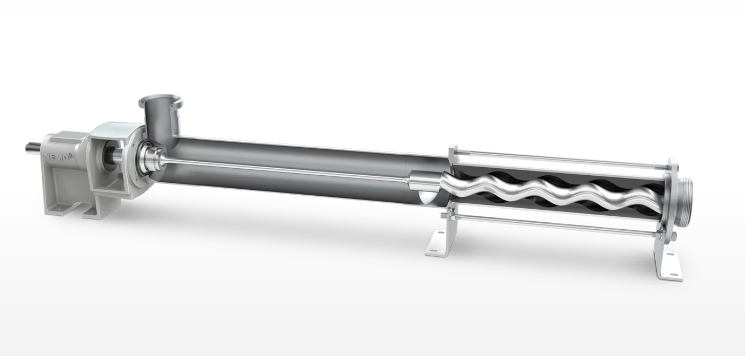

The BN5-12L rotor is a high-performance single-screw rotor designed and developed by seepex. It is made of special materials and has excellent wear resistance and corrosion resistance. The rotor is suitable for conveying viscous, fibrous and granular materials and is widely used in many industries.

Technical characteristics

The main technical characteristics of the seepex BN5-12L rotor include:

- Strong wear resistance: Made of high-quality alloy materials, it has excellent wear resistance and long service life after special heat treatment process.

- Good corrosion resistance: The rotor surface is specially coated with excellent corrosion resistance and is suitable for various corrosive media.

- Smooth operation: The rotor design is optimized, with low noise and vibration during operation, ensuring stable and reliable transportation.

- High efficiency and energy saving: The optimized rotor structure and flow channel design reduce energy consumption during transportation and improve the overall system efficiency.

- Convenient maintenance: The structure is simple and compact, and disassembly and maintenance work can be completed quickly, which greatly reduces maintenance costs.

Application field

The seepex BN5-12L rotor can be widely used in the following industries:

- Wastewater treatment: It can be used for the transportation and shearing of materials such as sludge, concentrated sludge, and sludge.

- Food processing: It is suitable for conveying high-viscosity, particle-containing food raw materials such as chocolate, meat paste, and jam.

- Chemical and pharmaceutical: It can be used to convey viscous materials such as chemical raw materials and pharmaceutical intermediates.

- Building materials production: It is suitable for the transportation and distribution of materials such as cement and concrete.

- Environmental protection field: It can be used for the transportation and treatment of various sludge, waste residue and other materials.

Advantages and characteristics

Compared with traditional sludge conveying equipment, the seepex BN5-12L rotor has the following outstanding advantages:

- Excellent sludge conveying capacity: The unique rotor design enables it to efficiently and stably convey various viscous, solid-containing sludge media.

- Excellent wear resistance: Made of wear-resistant materials, it has a long service life and low maintenance costs.

- Low energy consumption operation: The optimized flow channel design and high-efficiency motor significantly reduce energy consumption.

- Strong self-priming performance: Sludge can be directly sucked from the sludge tank or other containers without auxiliary equipment.

- Wide adaptability: The pump can be widely used in multiple industries to meet the needs of various occasions.

- Smooth and pulsation-free delivery: Smooth rotor operation is conducive to the stability of downstream processes.

poeple also ask

Send Your Enquiry :