[wpseo_breadcrumb]

Design and Features

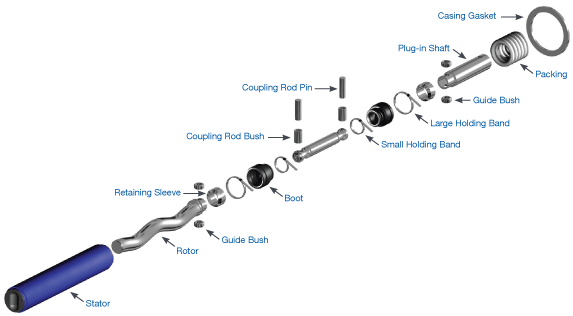

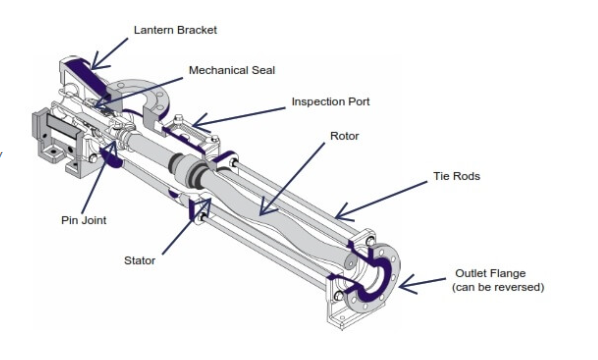

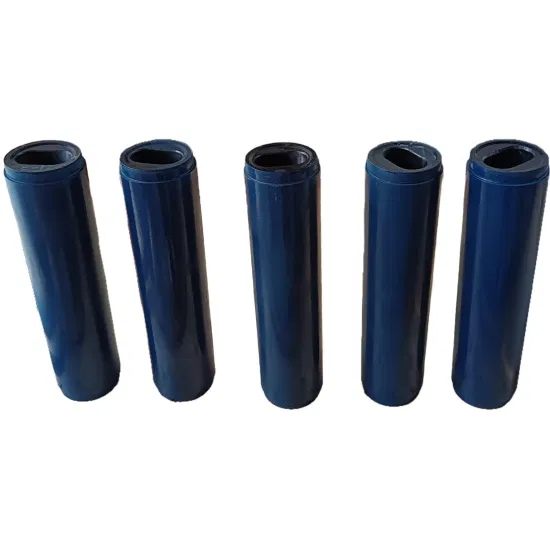

The Seepex BN75-6LT Rotor is designed with advanced engineering technology and has the following features:

- High wear resistance: The rotor is made of high-quality materials to resist wear and extend its service life.

- Optimized fluid dynamics: The shape of the rotor is carefully optimized to ensure that the turbulence of the fluid is effectively reduced and the flow efficiency is improved during operation.

- Adaptability: The design of the BN75-6LT Rotor can be adjusted as needed to adapt to the characteristics of different fluids for different working conditions.

Performance Advantages

Efficiency: The Seepex BN75-6LT rotor has good flow characteristics and can adapt to different working conditions. When running at low speed, it can still maintain high efficiency and reduce energy waste.

Durability: The BN75-6LT rotor is made of high-quality materials and has good wear and corrosion resistance. This allows it to maintain stable performance even in harsh working environments and extend the service life of the pump.

Flexibility: The BN75-6LT rotor is suitable for a variety of industries, including chemical, food, pharmaceutical, etc. This flexibility allows it to meet the needs of different customers while reducing the cost of equipment replacement.

Easy maintenance: Seepex also pays attention to the ease of maintenance of its products. The design of the BN75-6LT rotor allows users to perform routine maintenance and replacement without disassembling the pump body. This greatly saves maintenance time and improves the efficiency of equipment use.

Application areas

The Seepex BN75-6LT Rotor is widely used in multiple industries, including:

Food and beverage: In food processing, it is often necessary to handle viscous liquids such as slurries or thick juices. The BN75-6LT rotor can efficiently and harmlessly transport these sensitive materials.

Chemical industry: In chemical processing, corrosive or viscous fluids are often involved. The BN75-6LT Rotor can work safely under extreme conditions and maintain reliable performance.

Wastewater treatment: In sewage treatment plants, the BN75-6LT Rotor can efficiently transport various wastewaters and sludge to ensure the smooth progress of the treatment process.

people also ask

Send Your Enquiry :