[wpseo_breadcrumb]

Cavity pump technology has emerged as a revolutionary solution in various industrial applications, particularly in handling viscous fluids and slurries. This article explores the fundamental principles, advantages, applications, and future prospects of cavity pumps.

Understanding Cavity Pumps

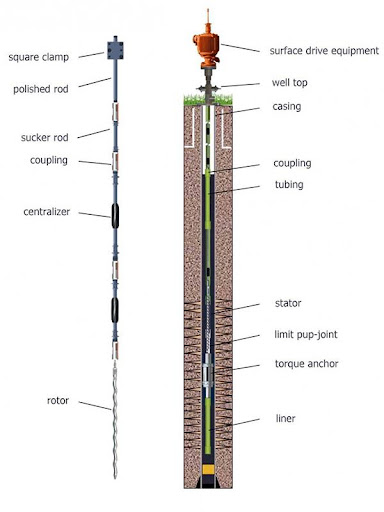

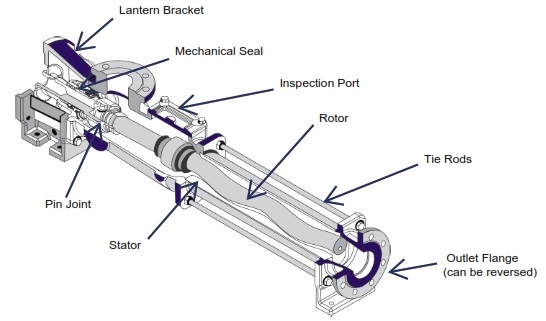

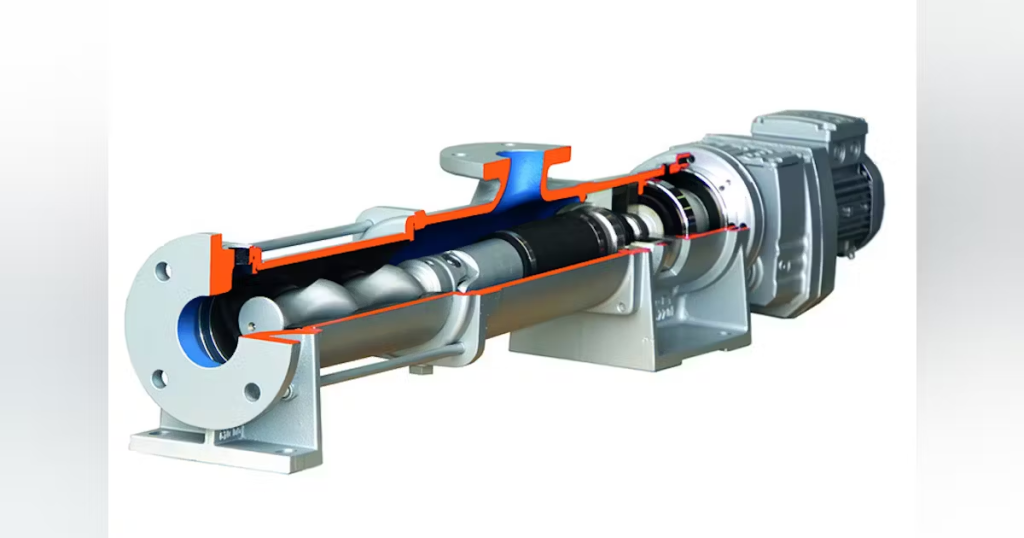

Cavity pumps, often referred to as progressing cavity pumps, operate on a unique mechanism that enables them to move fluids effectively. The core of the technology consists of a helical rotor and a stator. The rotor, which is typically made of metal, is designed to fit snugly within the elastomeric stator. As the rotor turns, it creates cavities that trap and transport the fluid along the pump’s length.

Key Components

- Rotor: The central component that rotates and creates the pumping action.

- Stator: The stationary part that houses the rotor and forms the cavities.

- Drive Mechanism: This can be electric, hydraulic, or mechanical, providing the necessary torque to rotate the rotor.

Advantages of Cavity Pumps

Cavity pumps offer several benefits that make them ideal for specific applications:

- Versatility: They can handle a wide range of fluid types, including viscous, shear-sensitive, and abrasive materials.

- Consistent Flow Rate: The design allows for a steady flow regardless of changes in pressure or viscosity.

- Self-Priming: Cavity pumps can operate without the need for external priming, simplifying installation and maintenance.

- Low Pulsation: The flow generated by cavity pumps is smooth, which is crucial for processes that require precise fluid delivery.

Applications of Cavity Pumps

The unique features of cavity pumps make them suitable for various industries:

1. Oil and Gas Industry

Cavity pumps are extensively used in the oil and gas sector for transporting crude oil, drilling mud, and other viscous fluids. Their ability to handle abrasive materials makes them indispensable in this field.

2. Food and Beverage Sector

In food processing, these pumps are utilized for transferring viscous products like sauces, pastes, and dairy products. Their sanitary design ensures that the products remain uncontaminated.

3. Chemical Manufacturing

Cavity pumps are ideal for moving chemicals and polymers, especially those that are sensitive to shear. Their ability to handle corrosive materials is another advantage.

4. Wastewater Management

In wastewater treatment facilities, cavity pumps are employed to transport sludge and other thick materials. Their efficiency in handling solids makes them a preferred choice.

5. Pharmaceutical Industry

The pharmaceutical sector benefits from cavity pumps’ precision and reliability, especially in the transfer of high-value products and active ingredients.

Challenges and Considerations

While cavity pumps offer numerous advantages, there are challenges that users should consider:

- Wear and Tear: The rotor and stator can experience wear over time, especially when handling abrasive materials. Regular maintenance is essential.

- Cost: The initial investment for cavity pumps can be higher than for other pump types, although the long-term benefits often justify the expense.

- Temperature Sensitivity: The materials used for the stator can be sensitive to heat, requiring careful monitoring of operating conditions.

Future Prospects of Cavity Pump Technology

The future of cavity pump technology appears promising, driven by innovations in materials and design. Researchers are exploring advanced elastomers that can withstand higher temperatures and corrosive environments, further broadening the applications of cavity pumps.

Trends to Watch

- Smart Pumping Systems: Integration of IoT technology allows for real-time monitoring and predictive maintenance, enhancing efficiency and reducing downtime.

- Energy Efficiency: Ongoing research aims to develop more energy-efficient models that minimize power consumption while maximizing performance.

- Sustainability: As industries move towards greener solutions, cavity pumps are being designed to minimize waste and energy use, aligning with global sustainability goals.

Conclusion

Cavity pump technology represents a significant advancement in fluid transportation. With their versatility, efficiency, and reliability, these pumps are poised to play a critical role across various industries. As technology continues to evolve, cavity pumps will likely become even more integral to modern industrial processes, ensuring that they meet the demands of a rapidly changing world.

Send Your Enquiry :