[wpseo_breadcrumb]

Cavity pumps, also known as progressive cavity pumps, are essential tools in various industrial applications. Their unique design allows them to handle a wide range of fluids, making them a favorite in sectors such as oil and gas, wastewater treatment, and food processing. This article explores the benefits, applications, and considerations when purchasing cavity pumps.

What Are Cavity Pumps?

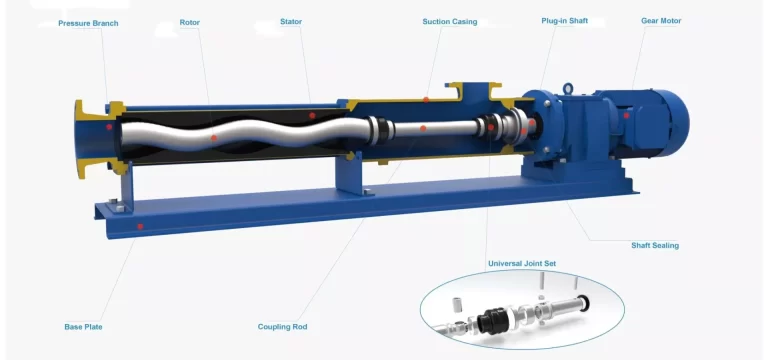

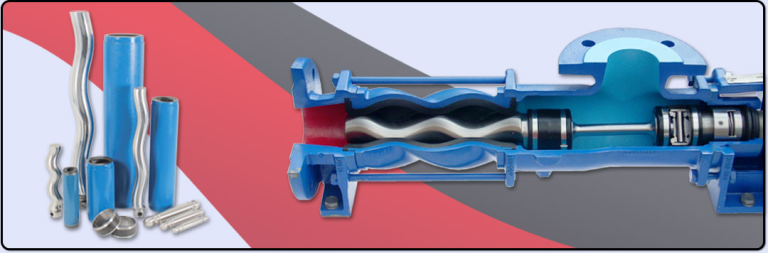

Cavity pumps use a helical rotor and a stator to create cavities that move fluids through the pump. This design enables them to handle viscous liquids, slurries, and even shear-sensitive fluids with ease. The progressive cavity mechanism ensures a steady flow, which is crucial for many industrial processes.

Key Features of Cavity Pumps

- Versatile Fluid Handling: They can manage various types of fluids, including viscous and abrasive substances.

- Steady Flow Rate: The design provides a consistent flow, reducing pulsations in the system.

- Self-Priming: Many models are capable of self-priming, making them easier to operate.

- Durability: Constructed from robust materials, cavity pumps are built to withstand harsh conditions.

Applications of Cavity Pumps

Cavity pumps find their place in numerous industries due to their adaptability. Here are some common applications:

- Oil and Gas: Used for transferring crude oil, chemicals, and other fluids in extraction and refining processes.

- Wastewater Treatment: Effective in moving sludge and other wastewater materials, ensuring efficient processing.

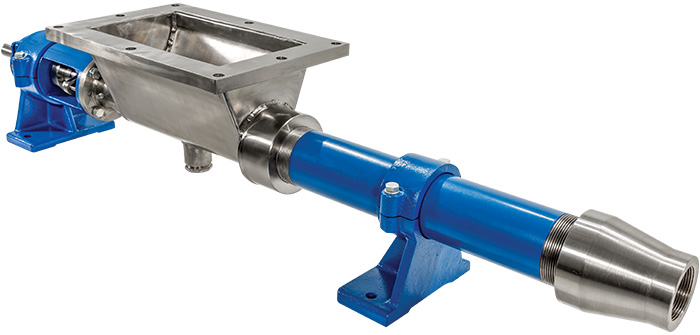

- Food and Beverage: Ideal for transferring viscous products like sauces, syrups, and other food items without damaging them.

- Pharmaceuticals: Employed in the transfer of sensitive compounds, ensuring integrity and safety.

- Mining: Used for pumping slurries and other materials in mineral extraction processes.

Benefits of Using Cavity Pumps

Investing in cavity pumps comes with several advantages:

1. Efficiency

Cavity pumps are designed for efficiency, providing reliable performance even under challenging conditions. Their ability to maintain a consistent flow reduces downtime and enhances productivity.

2. Cost-Effectiveness

While the initial investment may be higher than other pump types, their durability and low maintenance requirements often lead to lower overall costs. Additionally, their efficiency can result in energy savings over time.

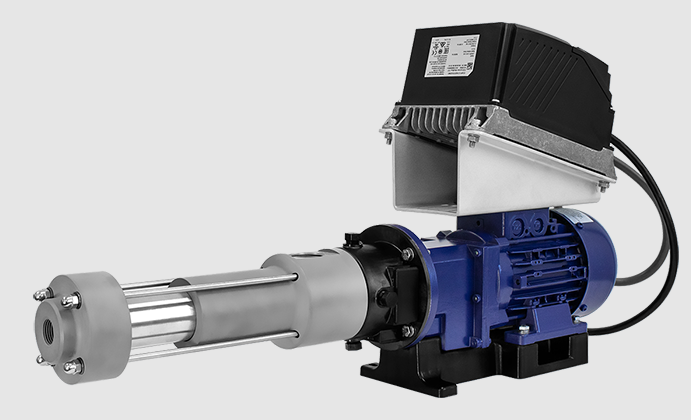

3. Customizability

Many manufacturers offer customizable options to suit specific industrial needs. This means you can find a cavity pump that perfectly fits your application, whether you need a certain size, material, or performance specifications.

4. Reduced Maintenance

Cavity pumps typically require less maintenance compared to other pump types, as their design minimizes wear and tear. This reliability is essential for industries where downtime is costly.

Considerations When Buying Cavity Pumps

When looking for cavity pumps for sale, several factors should be considered to ensure you make an informed decision:

1. Application Requirements

Identify the specific requirements of your application, including the type of fluid being pumped, viscosity, and any potential abrasiveness. This information will guide your selection process.

2. Material Selection

Choose a pump constructed from materials compatible with the fluids it will handle. For example, food-grade materials are necessary for food applications, while corrosion-resistant materials are essential for chemical processing.

3. Flow Rate and Pressure

Consider the required flow rate and pressure for your application. Different cavity pumps offer varying capacities, so it’s crucial to select one that meets your operational needs.

4. Manufacturer Reputation

Research manufacturers and their reputations in the industry. Look for companies with a track record of producing reliable and durable pumps. Customer reviews and testimonials can provide valuable insights.

5. Warranty and Support

Check the warranty and support options offered by the manufacturer. A good warranty can provide peace of mind, while reliable customer support is essential for addressing any issues that may arise.

Conclusion

Cavity pumps are a versatile and efficient solution for various industrial applications. Their unique design allows them to handle a wide range of fluids, making them indispensable in sectors such as oil and gas, wastewater treatment, and food processing. When considering purchasing a cavity pump, keep in mind the specific requirements of your application, material compatibility, and manufacturer reputation. Investing in the right cavity pump can lead to enhanced efficiency, reduced maintenance, and significant cost savings in the long run. Explore the options available and choose a pump that best meets your needs.

People also ask

Send Your Enquiry :