Cavity wall insulation is an essential aspect of modern building practices, ensuring that homes and commercial properties are energy-efficient and comfortable. One of the most effective ways to install cavity wall insulation is through the use of specialized equipment, specifically insulation pumps. In this article, we will explore the importance of cavity wall insulation, the benefits of hiring insulation pumps, and tips for a successful installation process.

Understanding Cavity Wall Insulation

Cavity wall insulation involves filling the gap between two layers of brickwork in a wall. This space, known as the cavity, can often allow heat to escape, leading to increased energy bills and a less comfortable indoor environment. By insulating this cavity, property owners can significantly improve their building’s thermal performance.

Benefits of Cavity Wall Insulation

- Energy Efficiency: Insulation helps retain heat, reducing the need for heating systems and thus lowering energy costs.

- Comfort: A well-insulated home maintains a more consistent temperature, making it more comfortable year-round.

- Soundproofing: Insulation can also reduce noise pollution, creating a quieter living environment.

- Environmental Impact: By reducing energy consumption, cavity wall insulation contributes to lower carbon emissions.

Why Hire an Insulation Pump?

Hiring an insulation pump can make the installation process more efficient and effective. Here are some reasons to consider hiring this equipment:

1. Professional Results

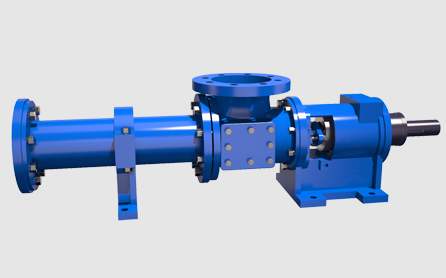

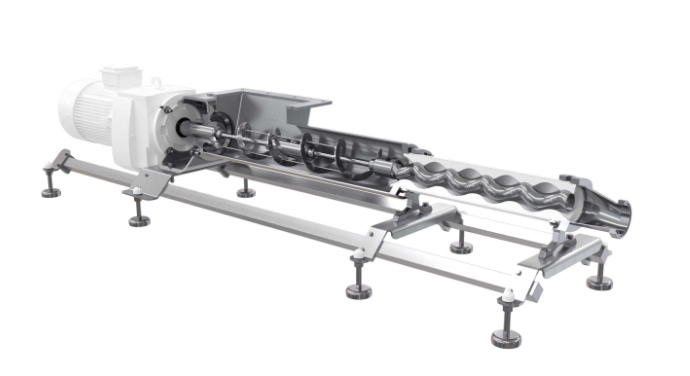

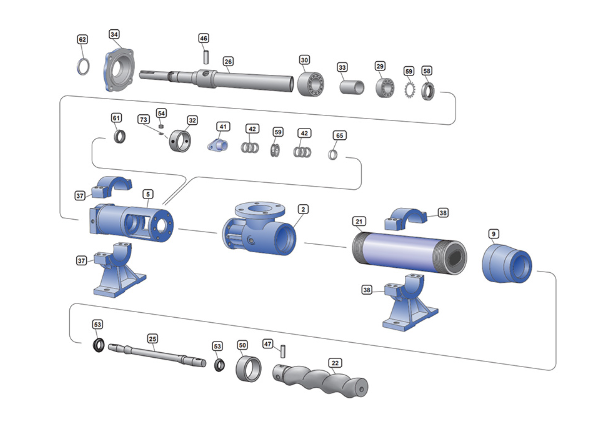

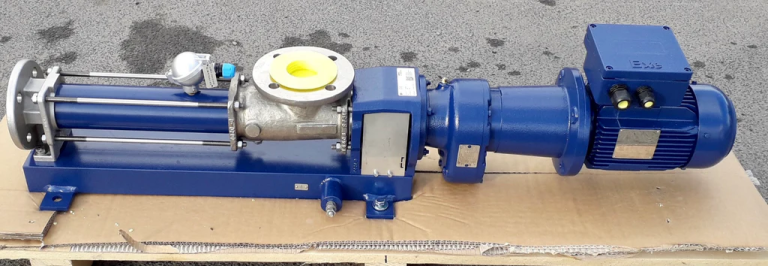

Using a high-quality insulation pump ensures a thorough and even application of insulation material. This professional-grade equipment can deliver the insulation at the right density, maximizing thermal performance.

2. Time Efficiency

Insulation pumps are designed for speed and efficiency. They can fill large cavities quickly, significantly reducing the time it takes to complete an installation compared to manual methods.

3. Cost-Effective

Hiring an insulation pump may be more cost-effective than purchasing one, especially for those who only need it for a single project. It allows access to high-quality equipment without the long-term investment.

4. Versatile Options

Most rental companies offer a variety of insulation pumps suited for different types of insulation materials, ensuring you find the right tool for your specific needs.

Preparing for Insulation Installation

Before diving into the insulation process, proper preparation is crucial. Here are some key steps to follow:

Assess Your Property

- Inspection: Examine the walls to identify areas needing insulation. Look for signs of dampness or cold spots.

- Access Points: Ensure there are sufficient access points for the insulation pump, ideally spaced evenly along the wall.

Choose the Right Insulation Material

Selecting the right insulation material is vital for achieving optimal results. Common options include:

- Polyurethane Foam: Excellent thermal performance and air sealing properties.

- Mineral Wool: Great for soundproofing, fire-resistant, and environmentally friendly.

- Polystyrene Beads: Lightweight and easy to install, suitable for various applications.

Safety Precautions

Safety should always be a priority during installation. Here are some precautions to consider:

- Protective Gear: Wear gloves, goggles, and masks to avoid exposure to insulation materials.

- Ventilation: Ensure the area is well-ventilated, especially if using materials that may release fumes.

The Insulation Process

Once preparations are complete, you can begin the insulation process. Here’s a simplified overview:

- Set Up the Pump: Follow manufacturer instructions to set up the insulation pump correctly.

- Fill the Cavities: Begin injecting insulation into the cavities, ensuring an even distribution throughout.

- Check for Gaps: After installation, check for any gaps or areas that may require additional insulation.

- Clean Up: Remove any excess material and clean the work area to leave it tidy.

Conclusion

Cavity wall insulation is an effective way to enhance energy efficiency and comfort in a property. Hiring an insulation pump streamlines the installation process, ensuring professional results without the commitment of purchasing equipment. By understanding the benefits, preparing adequately, and following best practices, you can achieve a successful cavity wall insulation project that will serve your property for years to come. Investing time and effort into this essential task not only improves your living space but also contributes to a more sustainable future.

People also ask

Send Your Enquiry :