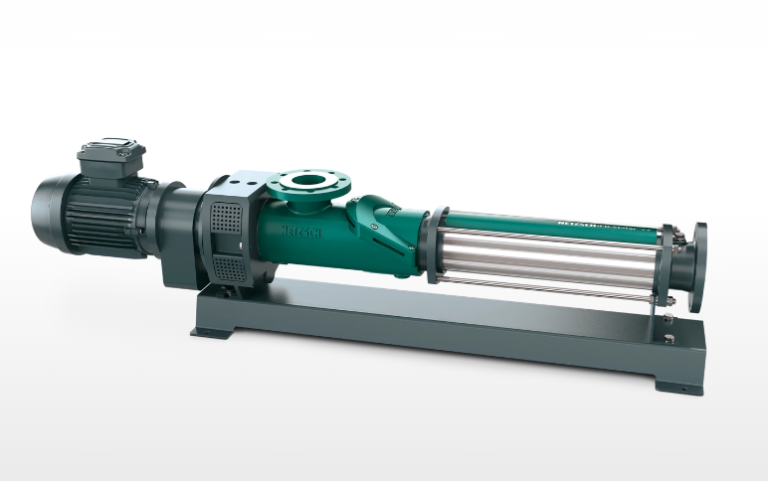

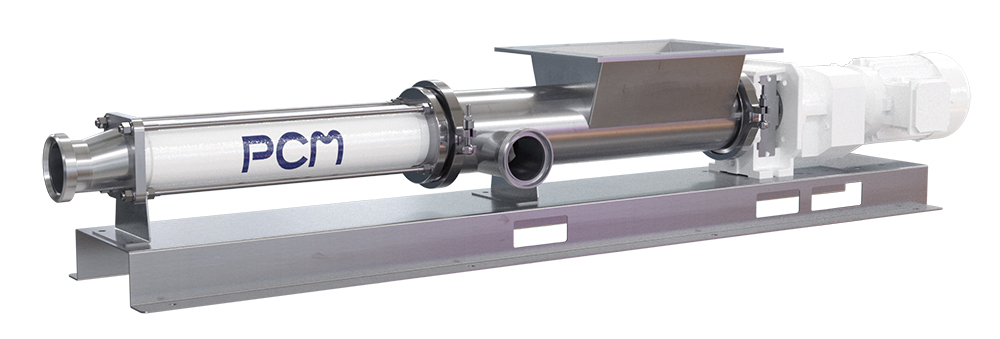

The Small Progressive Cavity Pump – A Helical Rotor Pump for Fluid Transfer

The small progressive cavity pump, also known as a helical rotor pump or a single screw pump, is a positive displacement pump that uses a single rotating screw to move fluid through the pump. The screw rotates inside a stator, which has a helical shape, creating a series of sealed cavities that move the fluid from the inlet of the pump to the outlet.

Small Progressive Cavity Pumps – Versatile and Ideal for Various Industries

Small progressive cavity pumps are widely used in many industries for various applications, such as food and beverage processing, chemical processing, wastewater treatment, and oil and gas production. They are particularly suitable for pumping viscous fluids with high solids content, as well as delicate fluids that require gentle handling.

Key Features of Small Progressive Cavity Pumps for Efficient Fluid Transfer

High Efficiency: Small progressive cavity pump have a high volumetric efficiency due to their positive displacement design, which means they can handle a wide range of viscosities and flow rates with low pulsation and shear.

Low Maintenance: These pumps have a simple design with few moving parts, and they are easy to maintain and repair in the field without dismantling the entire pump.

Self-Priming: Small progressive cavity pumps can self-prime against a dry suction line, eliminating the need for a separate priming mechanism.

Versatile: The design of these pumps allows them to handle a wide range of fluids, including abrasive, corrosive, and viscous fluids.

Cost-Effective: Small progressive cavity pumps offer a cost-effective solution for many applications, as they have a relatively low initial cost and low operating costs compared to other types of pumps.

Small Progressive Cavity Pump

Small progressive cavity pumps are versatile, efficient, and reliable pumps that are ideal for many different applications. With their simple design and low maintenance requirements, they offer a cost-effective solution for fluid transfer needs across a range of industries.

People also ask :

Send Your Enquiry :