Pump Screw-PMV Pump

People Also Ask

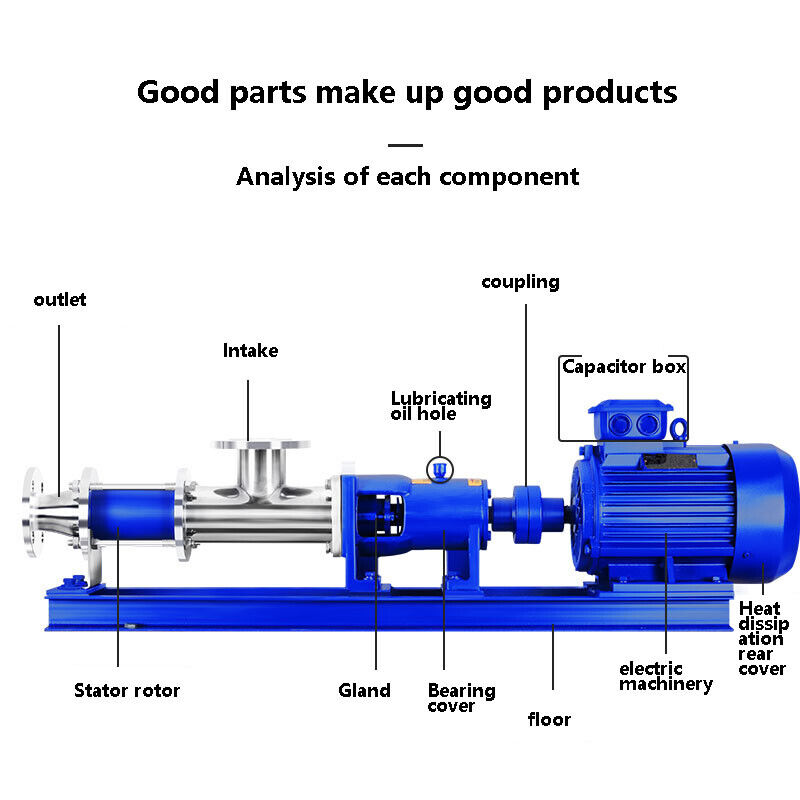

The G Type Single Screw Pump is an innovative solution designed for efficient fluid transfer across various industries. This type of pump stands out due to its unique design and operational principles, making it ideal for handling a wide range of fluids, including those that are viscous or contain solids.

The G Type Single Screw Pump operates on a simple yet effective mechanism. At its core, the pump consists of a single helical screw that rotates within a cylindrical casing. This design enables the pump to create a vacuum that draws fluid in while simultaneously pushing it out. The continuous flow generated by this screw mechanism minimizes turbulence and shear, ensuring the integrity of the fluid being pumped.

One of the key advantages of this design is its ability to handle various types of fluids. Whether it is thick sludges or delicate emulsions, the G Type Single Screw Pump can manage the transfer without compromising the quality. This versatility makes it suitable for applications in sectors such as food processing, pharmaceuticals, and chemical engineering.

The operational efficiency of the G Type Single Screw Pump is noteworthy. The pump’s design allows for a consistent flow rate, which is crucial in maintaining process stability. Additionally, its low maintenance requirements and durability contribute to reduced operational costs over time. The pump can also operate at varying speeds, enabling it to adapt to different flow requirements without sacrificing performance.

Moreover, the G Type Single Screw Pump is known for its ability to handle abrasive materials. This feature is particularly valuable in industries where the pumped fluid may contain solid particles that could cause wear in traditional pumps. The robust construction of the pump ensures longevity, making it a reliable choice for demanding applications.

The G Type Single Screw Pump finds applications in numerous fields. In the food and beverage industry, it is often used for transporting products like sauces, creams, and other viscous materials. Its gentle pumping action ensures that even sensitive products retain their quality during transfer.

In the chemical industry, this pump is essential for moving corrosive and abrasive fluids. Its ability to handle various chemical compositions makes it a versatile tool in production processes. Additionally, in wastewater treatment, the G Type Single Screw Pump efficiently manages sludge and other heavy materials, facilitating effective waste management.

In summary, the G Type Single Screw Pump is a superior choice for fluid transfer across multiple industries. Its innovative design, operational efficiency, and versatility make it an invaluable asset in various applications. By choosing this type of pump, businesses can ensure reliable performance and maintain the quality of the fluids they handle, ultimately contributing to enhanced productivity and cost-effectiveness.

People Also Ask

What is a screw pump? Screw pump is a part of the dry compressed gas transfer pump series. They are positive displacement pumps that use one or more screws to move fluid or water along the screw shaft. These screws interlock to pressurize the fluid and move it into the system. These screws engage each…

The Description of Screw Pump A screw pump is a type of positive displacement pump that utilizes an intermeshing screw and housing to transfer fluids or viscous substances. The pump consists of two or more screws (also known as rotors) that rotate in opposite directions, creating chambers that trap and move the fluid along the…

G Type Single Screw Pump Single Screw Pump Operating Principle and Benefits Single screw pump is a type of rotary positive displacement pump that operates based on the positive displacement principle. The pump works by creating sealed cavities through the interference fit of a single-helix metal rotor and a double-helix elastic stator. Due to the…

Single Screw pump What is single screw pump? Single screw pump is a type of rotary positive displacement pump that operate according to the positive displacement principle. Single screw pump working principle is based on the interaction between a single-helix metal rotor and a double-helix elastic stator, which creates sealed cavities that move fluid from…