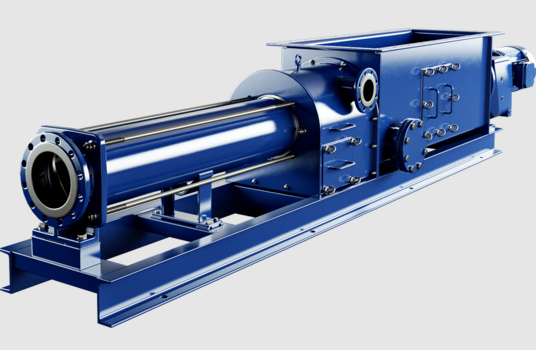

MOYNO G3 BRIDGE BREAKER Long-Coupled Pump

G3 – BRIDGE BREAKER High-performance 2000 Pumps offer low maintenance, minimal downtime and long service life for low total cost of ownership. People Also Ask

In today’s industrial and manufacturing environment, hopper pumps play an important role. This pumping device is usually used to handle fluid materials containing solid particles or fibers, such as coal powder, cement slurry, slag, etc. Hopper pumps consist of a funnel-shaped feed inlet and a rotating impeller, which can efficiently transport these difficult-to-flow materials to the designated location.

Compared with traditional centrifugal pumps, hopper pumps have unique advantages. They can automatically suck in materials without external pressurization devices, greatly improving the reliability and automation level of the system. At the same time, the design of hopper pumps can effectively prevent material blockage and sedimentation, greatly reducing the workload of maintenance and cleaning.

With the continuous development of industrial production, the demand for conveying complex fluids is becoming more and more urgent. With its excellent performance and flexibility, hopper pumps are widely used in various industries such as chemical, mining, building materials and other fields, showing its irreplaceable position. In the future, we can expect that hopper pump technology will be further improved and inject new impetus into industrial production.

G3 – BRIDGE BREAKER High-performance 2000 Pumps offer low maintenance, minimal downtime and long service life for low total cost of ownership. People Also Ask

Open Hopper Cavity Pump Introduction Open Hopper Cavity Pump is a type of positive displacement pump that is designed to handle viscous and shear-sensitive materials. It has an open hopper or feeding area which allows for easy loading and unloading of the material being pumped. The pump’s unique design features a rotor that rotates inside…

The Description of NETZSCH PUMP Netzsch pump is a type of positive displacement pump that utilizes a progressive cavity design to handle difficult-to-pump fluids with high viscosity, abrasiveness, and shear sensitivity. This type of pump is designed with a helical rotor and stator that create a series of sealed cavities to move fluid through the…

The Description of Pump Hopper A pump hopper is an equipment used in the process of transferring materials from one location to another using a pump. It is designed to receive, store and feed material into the pump system efficiently and safely. The Application of Pump Hopper Pump hoppers are widely used in various industries…

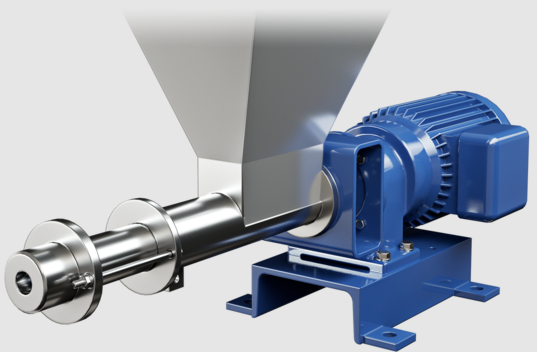

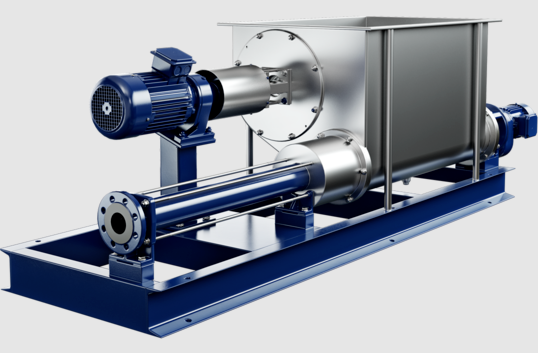

DESIGNED TO IMPROVE INTAKE EFFICIENCY ON HIGHLY VISCOUS MEDIA SEEPEX MDT range pumps are used to convey highly viscous media such as peanut butter, molasses, resins, and other media with low flowability. The open hopper on the pump directs media to the auger feed screw on the coupling rod which feeds the media into the…

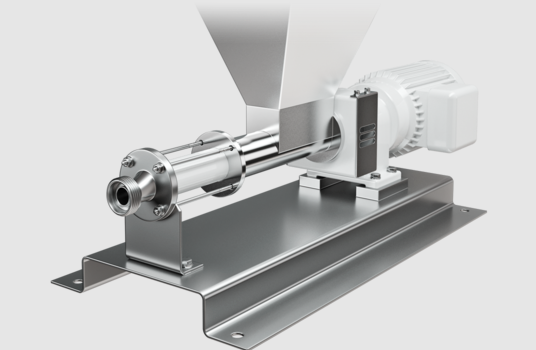

DESIGNED TO IMPROVE INTAKE EFFICIENCY ON HIGHLY VISCOUS MEDIA The MDTC range is the hygienic food grade version of the open hopper metering pump. It is used in a variety of applications in the food, beverage, pharmaceutical, and cosmetic industries to convey low to highly viscous media with low flowability. The pumps meet the highest…

MADE FOR EXTREMES Powerful under extreme conditions: the BTEX hopper pumps SEEPEX are robustly built and designed with reinforced individual components for tough applications – e.g. for fermentation products in the agriculture and biogas industries. They are designed to allow contaminants to settle at the base of the hopper and be removed quickly and easily…

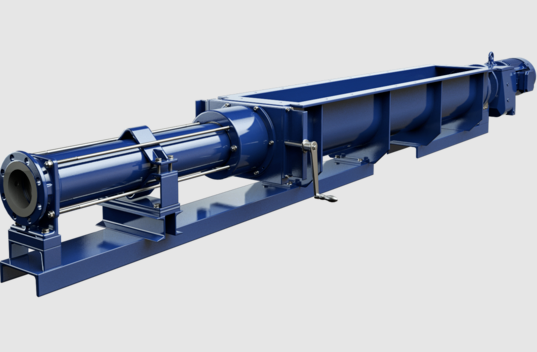

BTES – HOPPER PUMP FOR SILO SYSTEMS Made for silos: With their long hoppers, BTES hopper pumps from SEEPEX are ideal for installation under a silo. The construction of the rectangular hopper can then be optimally adapted to a wide variety of silo discharge systems. The pumps are ideal for pumping e.g. dewatered sewage sludge…

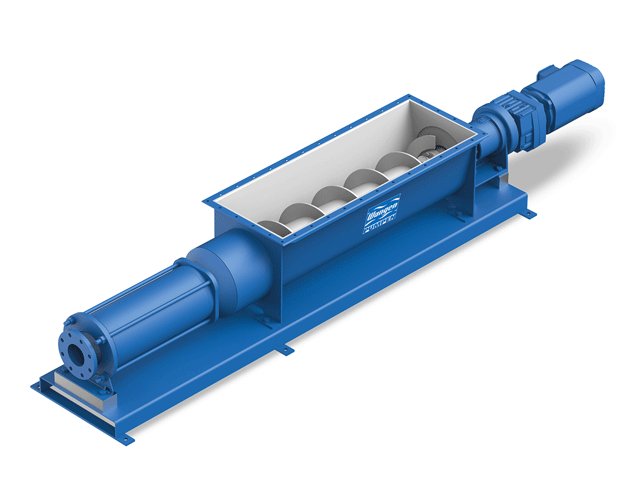

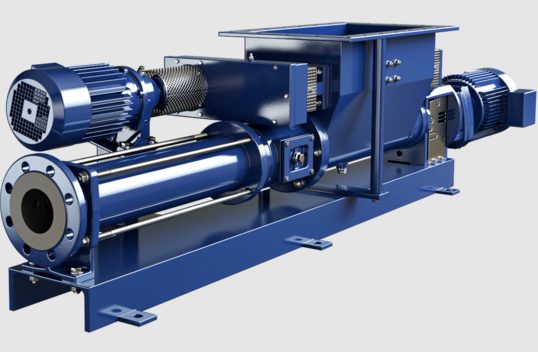

PERPETUAL MOTION No stoppages, no bridging: to ensure the feed medium can be optimally pumped at all times, there is a bridge breaker above the screw conveyor in the rectangular hopper of the BTEI hopper pump from SEEPEX. The separately driven rotating paddle keeps the medium in constant motion, thus avoiding the formation of bridges….

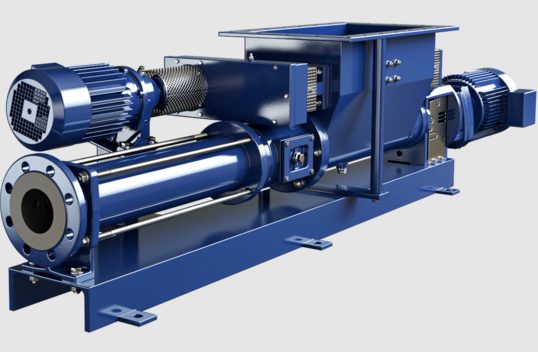

REALLY WELL MIXED When media are inclined to bridging, smooth product delivery to the conveying elements cannot always be assured. The BTI hopper pumps from SEEPEX provides a solution. The rectangular hopper contains two counter-running paddle shafts equipped with their own drive system. These mix highly viscous media so thoroughly that bridging cannot even begin…