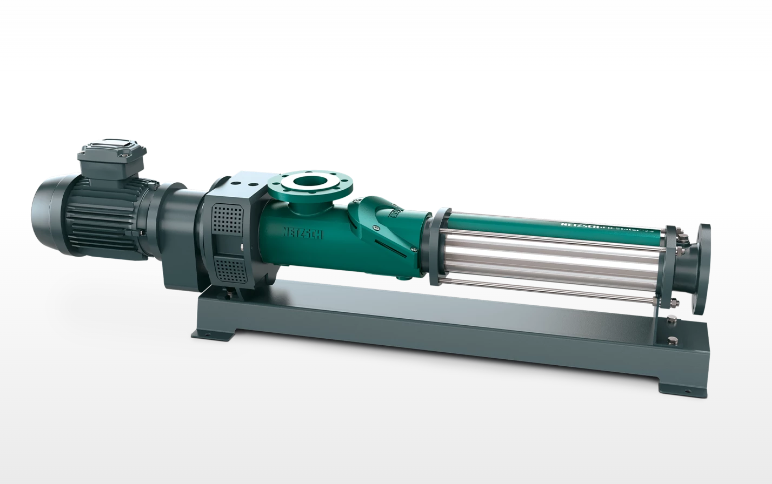

Netzsch nm053by01l06b Repleacement Pump

Netzsch nm053by01l06b The Netzsch NM053BY01L06B screw pump is a reliable and versatile pumping solution widely used in various industries. This article provides a comprehensive overview of the pump, including its description, applications, notable features, and a brief explanation of how it works.