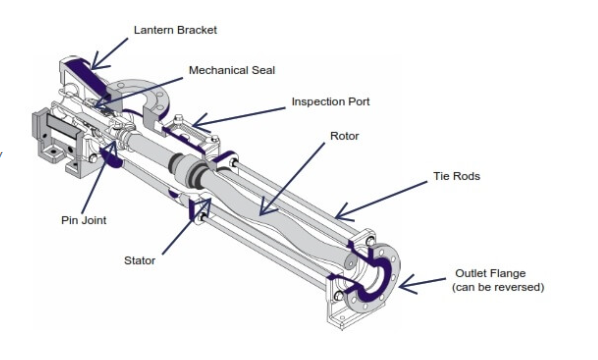

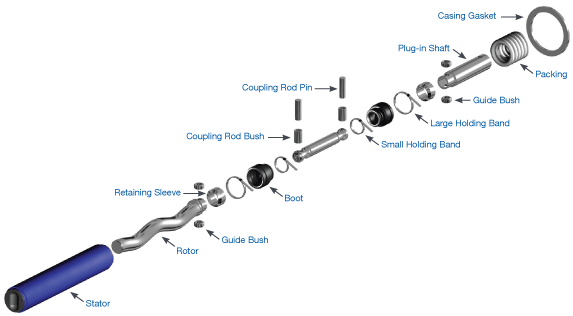

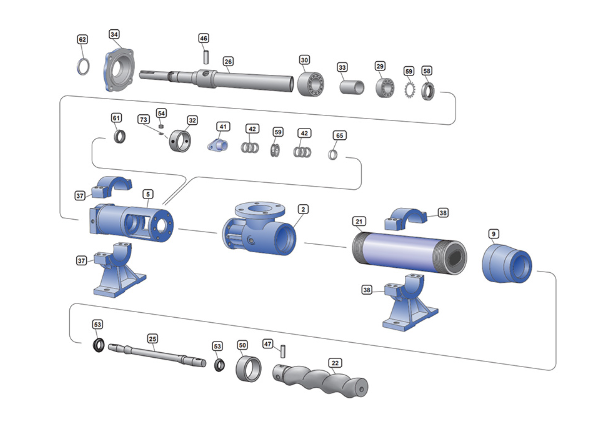

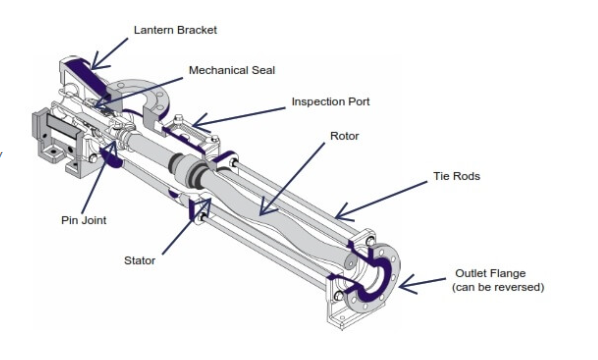

Progressive Cavity Pumps Design

What are Progressive Cavity Pumps? Progressive cavity pumps, also known as PC pumps, progressing cavity pumps, eccentric screw pump and mono pumps are a type of rotary positive displacement pump designed for the conveying of liquids and sludges from 1cst to 1Million. They handle not only viscous fluids and solids but also gassing or multiphase…