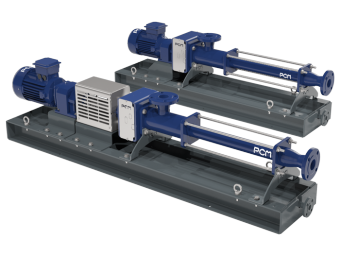

PCM Pump-PMV

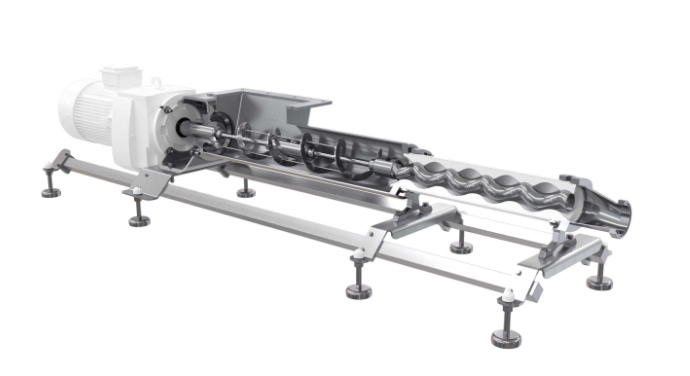

The Description of PCM Pump PCM Pump is a leading manufacturer of progressive cavity pumps, offering reliable and efficient solutions for various industries. Their pumps are known for their robust construction, precise engineering, and exceptional performance. PCM Pump’s progressive cavity pumps are designed to handle a wide range of fluids, including viscous, abrasive, and shear-sensitive…