PCM VERTICAL PROGRESSING CAVITY PUMPS

The PCM Moineau™ AV vertical progressing cavity pump is the ideal solution for upstream and downstream oil & gas applications within onshore and offshore facilities. It combines API standards with our unrivalled industry expertise.

The Description of PCM VERTICAL PROGRESSING CAVITY PUMPS

PCM Moineau™ AV vertical API pumps are designed for installation directly into a tank, pit, vessel or drum and offer exceptional opportunities to save space, simplify your system, and minimise associated capital equipment costs.

Installing a PCM Moineau™ AV vertical pump directly into the fluid source eliminates upstream pressure losses, maximising the Net Positive Suction Head

The Application of PCM VERTICAL PROGRESSING CAVITY PUMPS

The application of PCM vertical progressing cavity pumps is widespread across various industries. These pumps are specifically designed to handle challenging fluid transfer applications efficiently. Here are some common applications of PCM vertical progressing cavity pumps:

- Oil and Gas: Well dewatering, crude oil transfer, chemical injection, and enhanced oil recovery.

- Mining: Slurry transfer, tailings disposal, mine dewatering, and underground pumping.

- Water and Wastewater Treatment: Sewage, sludge, activated carbon, and lime slurry pumping.

- Food and Beverage: Syrups, dairy products, sauces, liquid sugar, chocolate, and fruit concentrates.

- Chemical and Petrochemical: Handling various chemicals, solvents, acids, and bases.

- Pharmaceutical: Transferring delicate liquids, creams, ointments, and maintaining sterility.

- Power Generation: Fuel oil transfer, sludge handling, and other fluid transfer applications.

These are just a few examples of the broad range of applications where PCM vertical progressing cavity pumps are utilized. Their versatility, reliability, and ability to handle challenging fluids make them indispensable in various industries.

PCM Moineau™ AV vertical PCP Specifications

Quality records

- Material certification to EN10204 for pressure wetted metallic parts.

- NACE certification for sour service.

- API inspection & testing options; performance, hydrostatic, NPSH, noise and vibration.

- Non-destructive examination.

- API documentation

Materials

- Multiple options for a wide variety of applications, including carbon steel, stainless steel, and corrosion resistant alloys.

- Hardwearing chromium plated rotors for low friction and abrasion resistance.

- A range of elastomer stators, formulated by PCM elastomer experts in our state of the art laboratory, and manufactured in house.

PCM Moineau™ AV vertical PCP Performances

| Maximum flowrate | 108m3/hr (450 Usgpm) |

| Maximum differential pressure | 24 bar (350 psi) |

| Maximum fluid temperature | 130°C (265°F) |

| Minimum fluid temperature | -12°C (10°F) |

| Ambient temperature range | -40°C to +55°C / -40°F to +130°F |

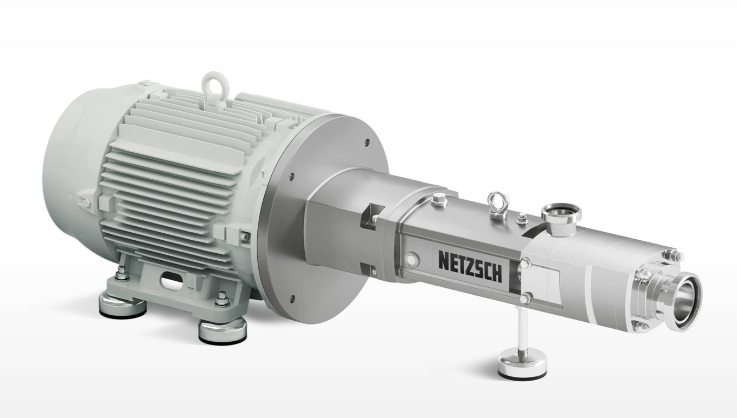

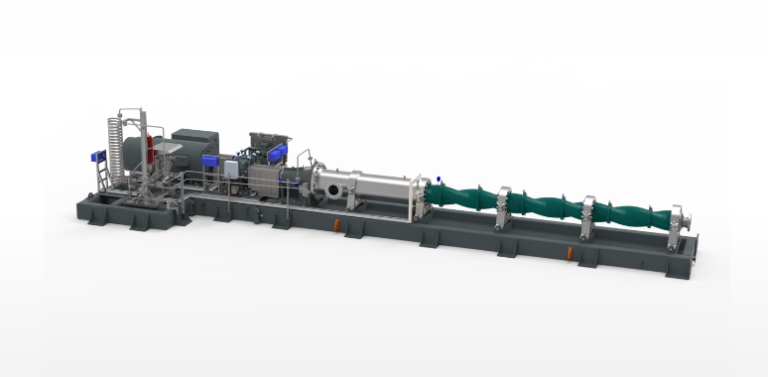

MOINEAU™ PROGRESSING CAVITY CRUDE OIL TRANSFER PUMPS

Founder of the PCM company in 1932, René Moineau is the inventor of the Progressing cavity pump, also known as « Moineau pump ». PCM provides cost-effective oil pumps integrated within our pumping systems, as well as oilfield services for a range of surface transfer needs, including API 676 compliance.

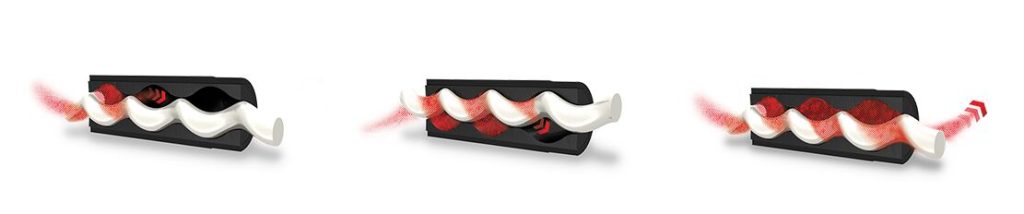

Progressing cavity pump principle

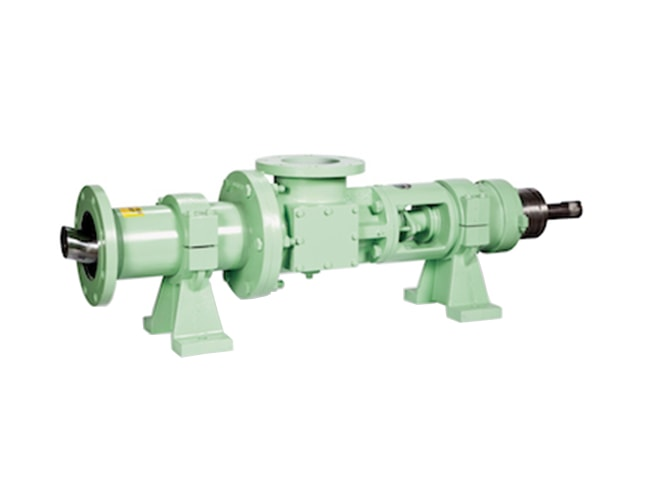

PCM Moineau™ transfer pumps use patented PCP technology to provide optimal performance for all applications. Our Progressing Cavity Pump comprises a metallic rotor with a helical profile, as well as an elastomeric stator with a double helix profile.

When the rotor is assembled within the stator, a series of sealed cavities are formed inside the pump, each of identical size and profile. When the pump is running, the rotor turns, allowing the cavities to move in a spiral path from one end of the pump to the other. This conveys fluid from the inlet to the outlet of the pump.

Rotor

The pump’s rotor is manufactured from high strength steel, and is coated to minimize abrasion from pumped fluids whilst reducing rotor/stator friction. The rotor is machined using a special lathe to achieve a precise diameter. This allows it to work effectively in combination with your chosen stator design, and for your specific application.

Stator

The stator is made from one of a range of elastomers which are formulated to suit a variety of pumped fluids and applications, up to temperatures of 150°C (300°F). The stator’s design is also influenced by mechanical strength, as well as chemical and abrasion resistance.

PCM is proud of its status as one of the few oil pump manufacturers to develop its own elastomers in-house – and we’ve been doing so for over 80 years, giving us unrivalled expertise in the business.

People Also Ask

Send Your Enquiry :