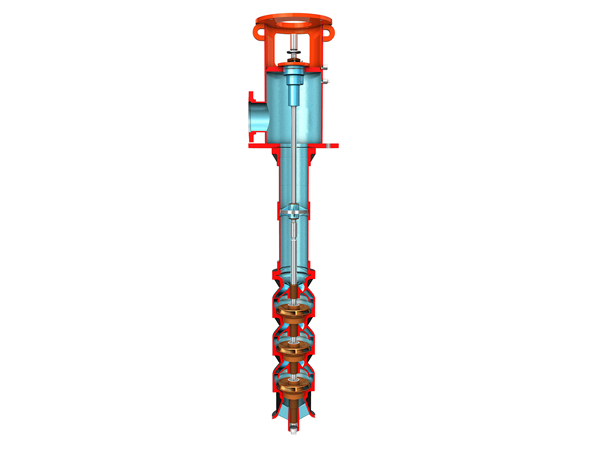

Netzsch Parts-Pumpvv

The Description of Netzsch Parts Netzsch Parts are high-quality replacement components designed to fit Netzsch pumps and systems. These parts are manufactured with precision to ensure optimal performance and reliability. The Application of Netzsch Parts Netzsch Parts are suitable for various industrial applications such as chemical processing, oil and gas, pharmaceuticals, food and beverage, and…