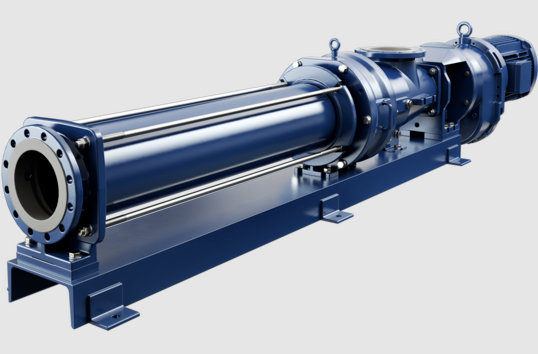

Small Progressive Cavity Pump-PMV Pump

People also ask :

A large variety of corrosive and viscous fluids are used in various industries to carry out regular processes. Many of these fluids require special pumping equipment and systems such as progressive cavity pumps, which helps in handling viscous slurries. Today, it is easy to find progressive cavity pumps from different brands,These pumps are equipped with various parts that contribute to their proper functioning in harsh environments. These parts may wear out due to continuous exposure to elements such as moisture, acidic mixture, heat, and thus require replacements.

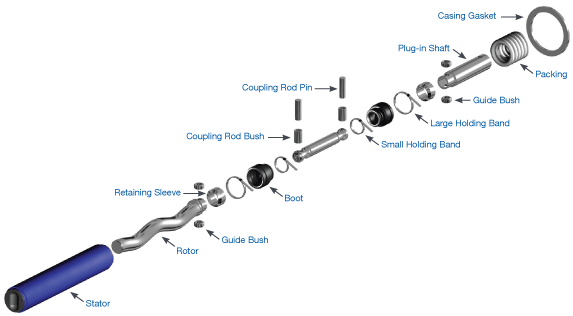

The stator is mostly made of rubber. Since it needs to form a closed meshing cavity with the rotor, it has an interference fit with the rotor. When the rotor (spindle) rotates and causes constant friction, it will naturally wear out.

The screw pump rotor (also known as the main shaft) is mostly made of stainless steel and can be selectively chrome-plated; due to its meshing relationship with the characteristic geometric shape of the stator, in addition to natural wear, it is also related to whether the conveying medium contains solid particles and corrosiveness.

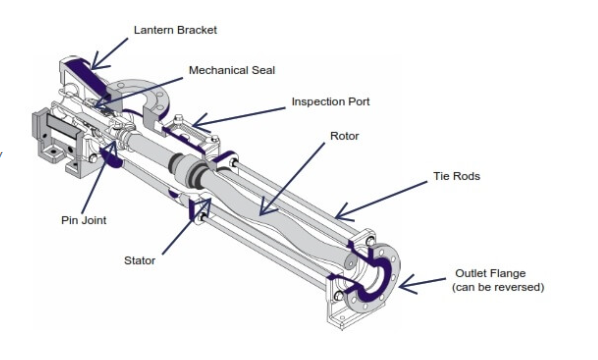

The coupling is a metal pump part that connects the rotor and the drive shaft in the screw pump. The connecting rod connects the rotor and the transmission shaft. When the motor is running, the transmission shaft drives the connecting rod, and the connecting rod drives the rotor to transmit the power. Except for the transmission shaft, these mechanical parts are all located in the suction chamber of the pump.

The drive shaft is the metal pump part located between the connecting rod (consisting of a universal joint group) and the drive end (such as a reducer or various drive motors). Its wear is mostly caused by natural wear or changes in medium working conditions.

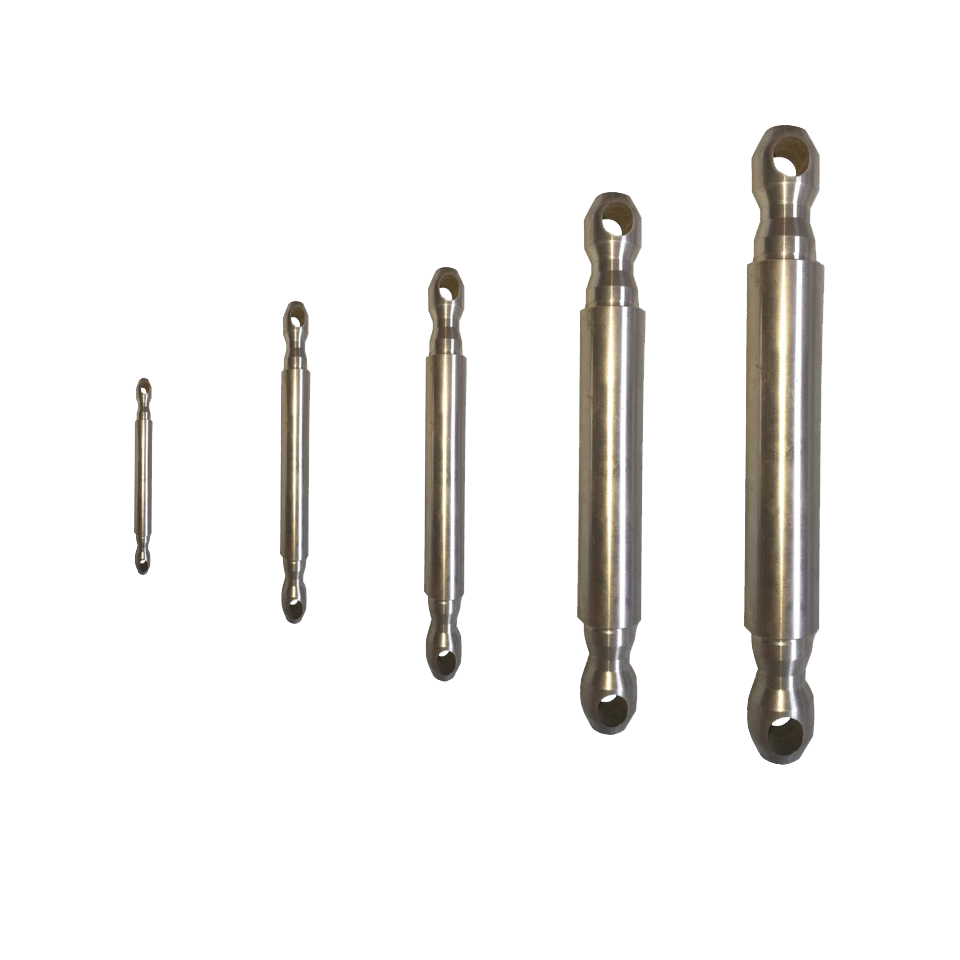

The universal joint group is also called the universal joint assembly. The universal joint assembly is located at both ends of the connecting rod. It successfully connects the rotor and the drive shaft to the connecting rod more stably and firmly. Since the universal joint assembly is composed of a variety of small parts, we need to check its sealing and lubrication regularly.

As a key equipment for handling special fluids such as viscous slurries, screw pumps play an important role in all walks of life. Regular maintenance of key components of screw pumps, such as stators, rotors, coupling rods, drive shafts, universal joint components, etc., is a key step to ensure its efficient operation and extend its life. Therefore, regular inspection, maintenance and replacement of key components of screw pumps will help reduce the occurrence of failures, improve equipment reliability, and ensure the smooth progress of the production process.

People also ask :

What are Progressive Cavity Pumps? Progressive cavity pumps, also known as PC pumps, progressing cavity pumps, eccentric screw pump and mono pumps are a type of rotary positive displacement pump designed for the conveying of liquids and sludges from 1cst to 1Million. They handle not only viscous fluids and solids but also gassing or multiphase…

The Description of Moyno Progressive Cavity Pumps Moyno progressive cavity pumps are renowned for their exceptional performance and reliability. These pumps are specifically designed to operate as both screw pumps and progressive cavity pumps, offering versatility in fluid handling applications. With their unique design and construction, Moyno pumps provide efficient and precise fluid transfer, ensuring…

About PMV Pump Stator. The stators are made in molds of our own design & construction. The main property of the rubber is that it is resistant to abrasion, tear and to chemical agents. With this objective we use the appropriate rubber in each case and carry out resistance tests for specific types of abrasion….

The Description of PCM Pump PCM Pump is a leading manufacturer of progressive cavity pumps, offering reliable and efficient solutions for various industries. Their pumps are known for their robust construction, precise engineering, and exceptional performance. PCM Pump’s progressive cavity pumps are designed to handle a wide range of fluids, including viscous, abrasive, and shear-sensitive…

People Also Ask