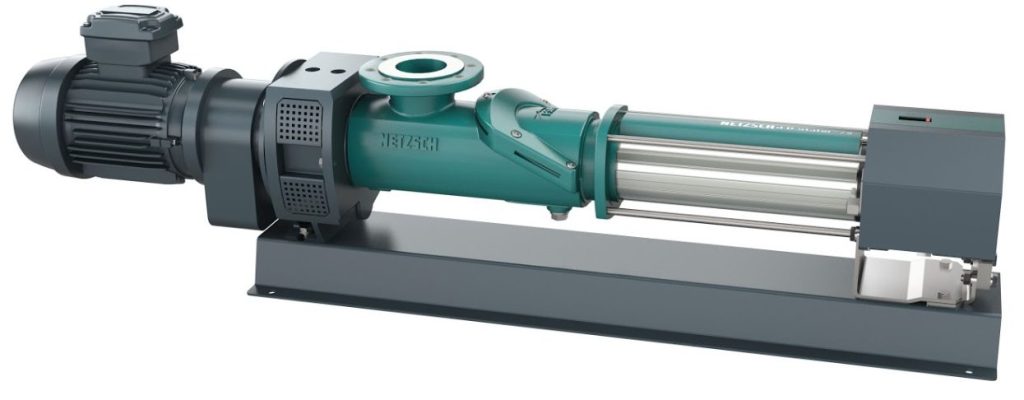

Hopper progressive cavity pump in block construction

Hopper progressive cavity pump in block construction Q=0.5 m³/h – 120 m³/h (2.2 USGPM – 528 USGPM) P=0~2.4Mpa (0~350 psi) CONTACT What is the open hopper feed progressive cavity pump in block construction? The open hopper progressive cavity pump in block construction is a kind of direct-coupled progressing cavity pump, its hopper is usually square or rectangular,…