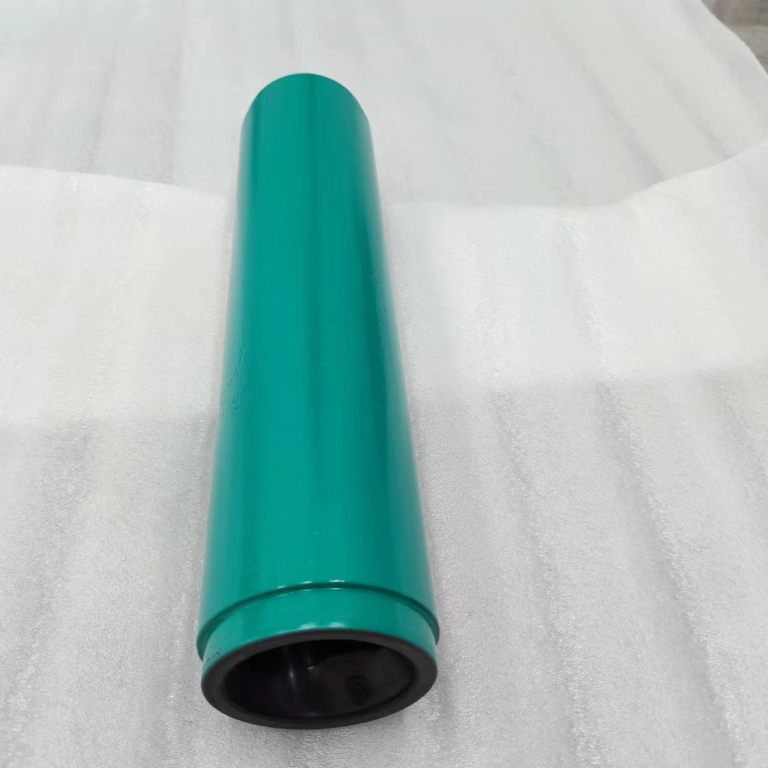

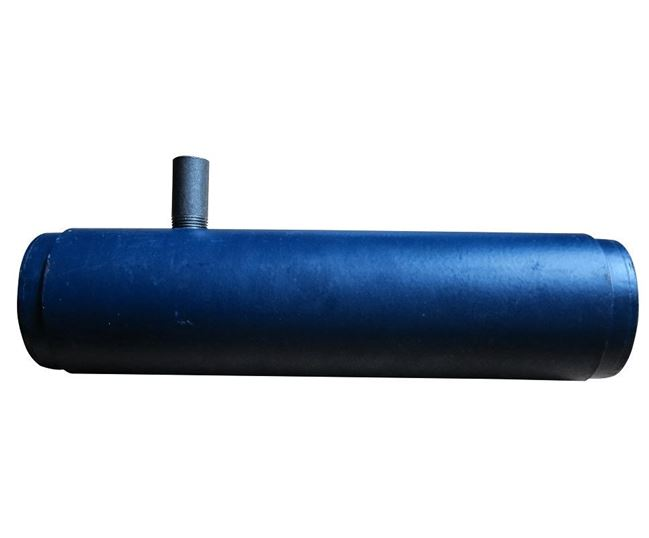

BN52-12L stator seepex

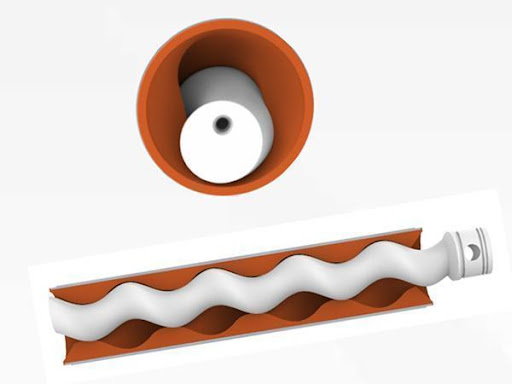

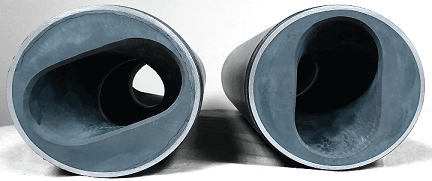

Advantages of seepex BN52-12L stator seepex BN52-12L stator is widely favored in the industrial field due to the following advantages: Excellent working performance Optimized flow channel design ensures a conveying efficiency of more than 90% Wide compatibility, suitable for viscous, granular or easy-to-crystallize media Excellent self-priming performance, greatly reducing the initial startup pressure of the…