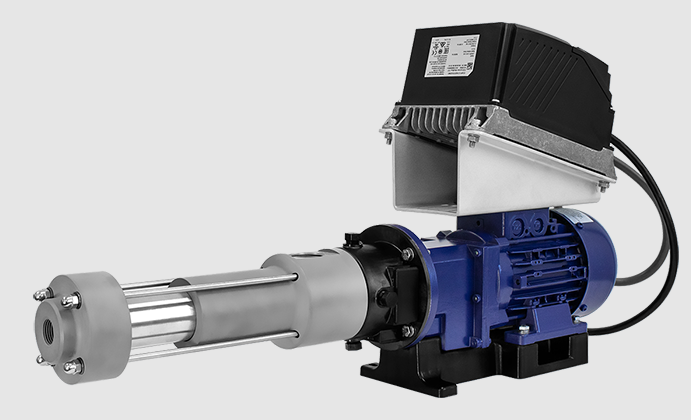

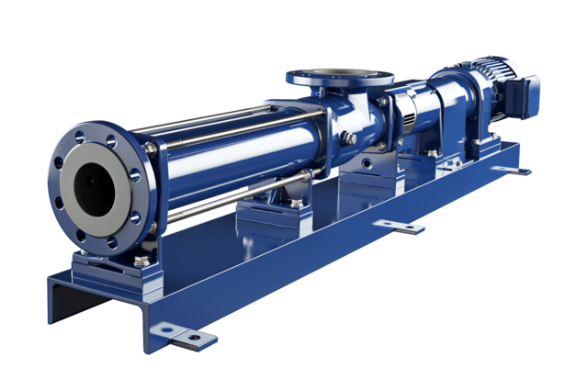

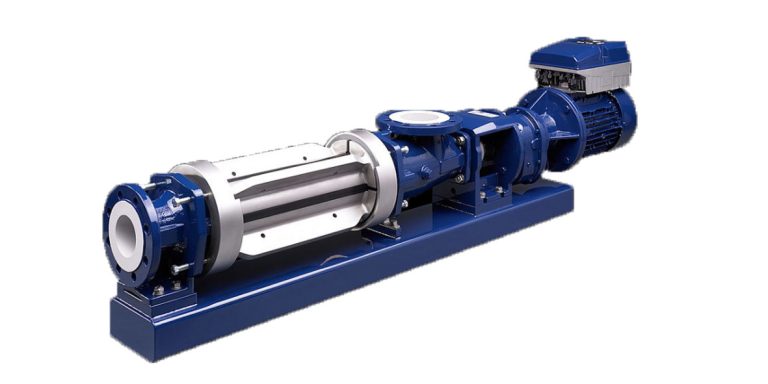

BN30-12T stator seepex

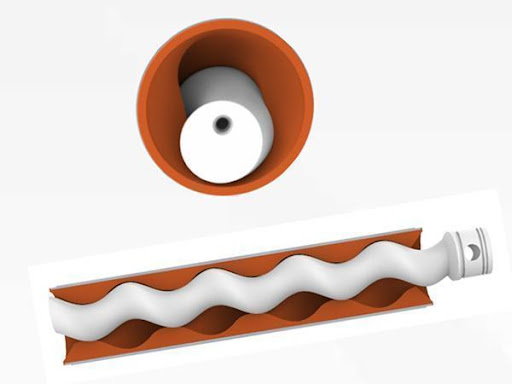

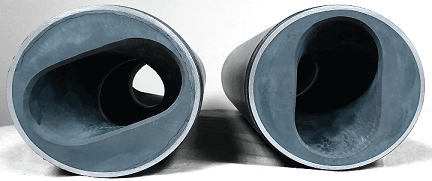

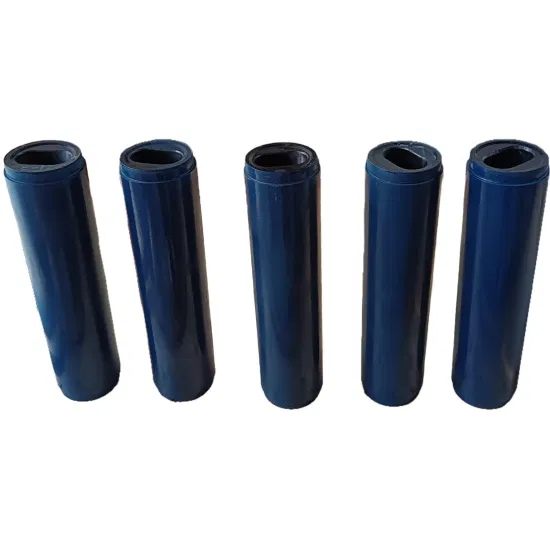

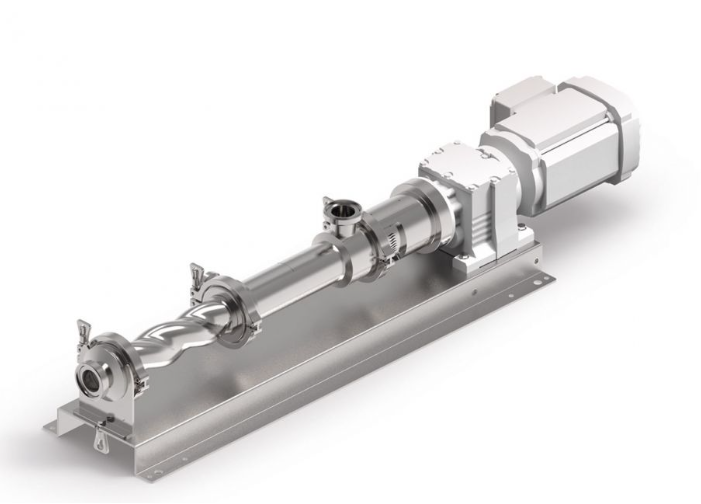

Design features The seepex BN30-12T stator uses high-quality materials and advanced manufacturing processes. The stator of this pump has good wear and corrosion resistance and can withstand various harsh working environments. Its design takes into account the basic principles of fluid dynamics, making the fluid flow in the pump smoother, thereby reducing energy loss. Performance…