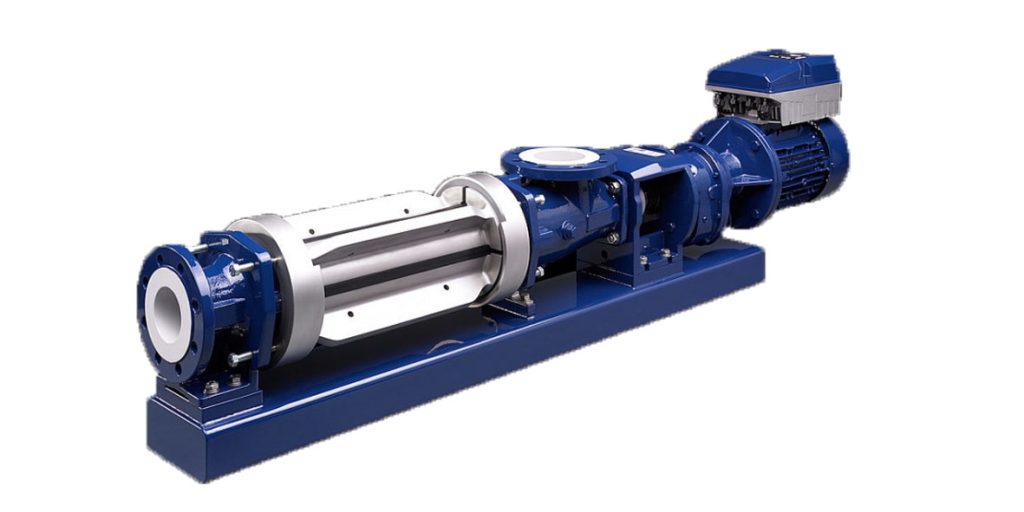

SCT – SMART CONVEYING TECHNOLOGY

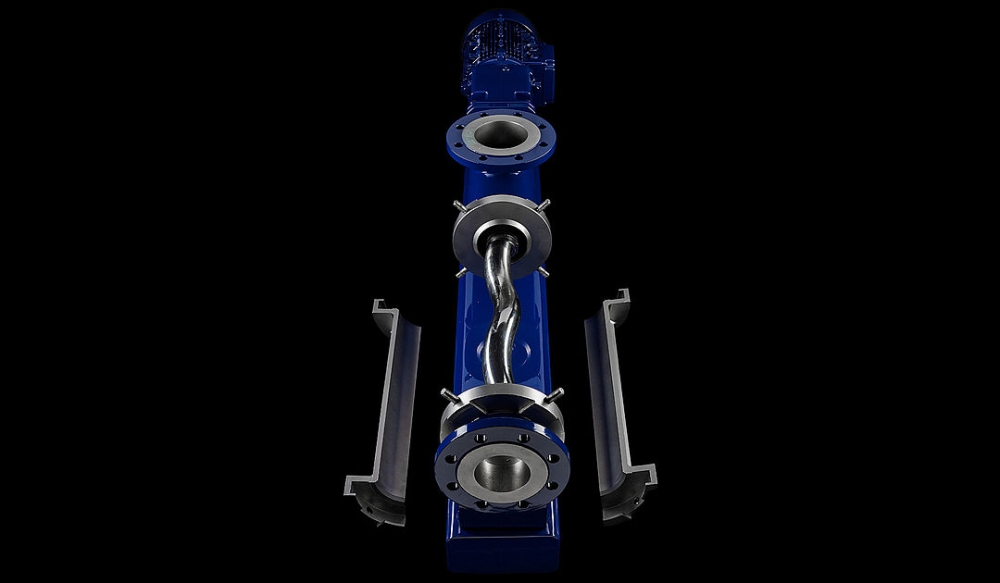

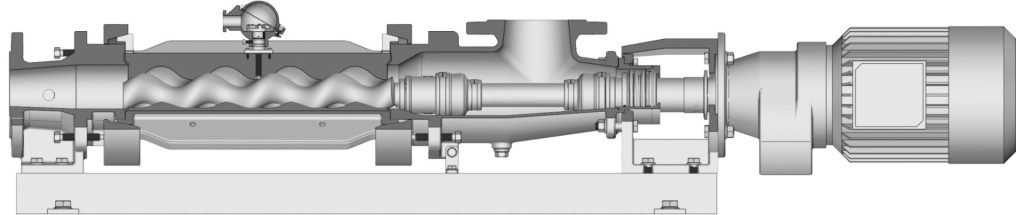

The patented Smart Conveying Technology (SCT) ensures the fastest maintenance possible resulting in reduced downtime and significantly reduced life cycle costs in virtually all market sectors. The Smart Stator and Rotor are both manufactured in two pieces allowing the pump to be maintained without the need to remove either the suction or discharge pipe work resulting in an 85% reduction in maintenance times.

The description of SCT Progressive Cavity Pumps

The unique design of SCT enables the sealing line between the rotor and stator to be adjusted to suit the required application and also to compensate when wear starts to occur, typically resulting in more than doubling the life of the rotor and stator.

| Product Category | iquid Handling Pumps |

| Pump Type | Displacement Pump; Progressing Cavity Pump |

| Discharge Pressure | 58.0 to 116.0 psi (40.79 to 81.58 m of Water) |

| Reduced maintainance time | by up to 85 % |

| Longer life span | up to 200% |

| Life cycle costs | significantly reduced |

| Due to lower energy requirements | High Efficiency |

Application of SEEPEX SCT Progressive Cavity Pumps

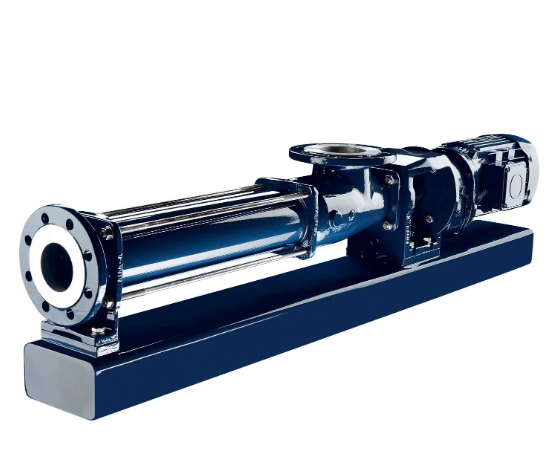

SEEPEX SCT Progressive Cavity Pumps are versatile and reliable pumps that can be used in a variety of applications across numerous industries. These pumps are particularly effective for handling shear-sensitive, viscous, and abrasive liquids, making them ideal for use in food and beverage, chemical processing, wastewater treatment, and oil and gas industries.

With their precision-engineered design, SEEPEX Progressive Cavity Pumps offer consistent, predictable performance with minimal downtime or maintenance. They are capable of handling high-viscosity fluids with ease, ensuring efficient and reliable operation even in the most challenging conditions.

Whether you need to transfer highly viscous liquids, meter precise amounts of chemicals, or move abrasive slurries, SEEPEX SCT Progressive Cavity Pump is the ideal solution. With their rugged construction, advanced features, and exceptional performance, these pumps provide unmatched value and reliability for a wide range of industrial applications.

Reduced downtime

Reduction in maintenenance time by up to 85%

Increased service life

Integrated retensioning device resulting in up to 200% increase in the life of the rotor and stator

Maintain in Place

Two-piece Smart Stator and Rotor allow the pump to be maintained in place without the need to remove the suction or discharge pipe work or the use of any special tools

Increased productivity

High energy and performance efficiency due to the in-built retensioning device which allows the the clamp between the rotor and stator to be adjusted for optimum performance

Environmentally friendly

Free molded stator halves can be easily recycled due to the lack of the stator tube.

Replacment of the rotor does not require additional universal joint components or lubricants

Retrofit-Option

The SCT Retrofit-Kit allows an existing conventional tube stator pump to be upgraded without the need to modify the pipework or base plate

Ease of installation

As SCT pumps do not require any pipework to be removed during maintenance, additional ‘spool’ pieces are not required to be fitted reducing installation costs and overall footprint

People Also Ask

Send Your Enquiry :