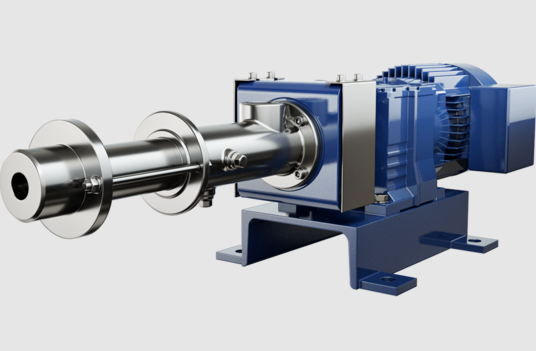

MOYNO G4 – 45 INLET DESIGN PUMPS

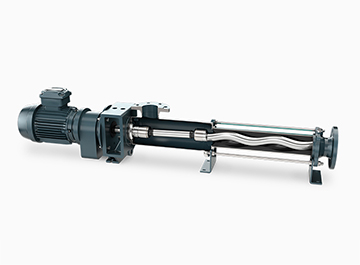

G4 – 45 INLET DESIGN The high-efficiency G4 progressing cavity pump’s 45°inlet lowers friction loss and provides for gentler handling of the product. People Also Ask

The main working parts of a single screw pump are composed of a sleeve (stator) with a double-headed spiral cavity and a single-headed eccentric screw (rotor) meshed with it in the stator cavity. Since the medium of a single screw pump is pushed axially and evenly to flow, the internal flow velocity is low, the pressure is stable, and no eddy current or agitation is generated; it is suitable for conveying high viscosity, containing solid particles or high fiber, and requiring continuous and stable pressure.

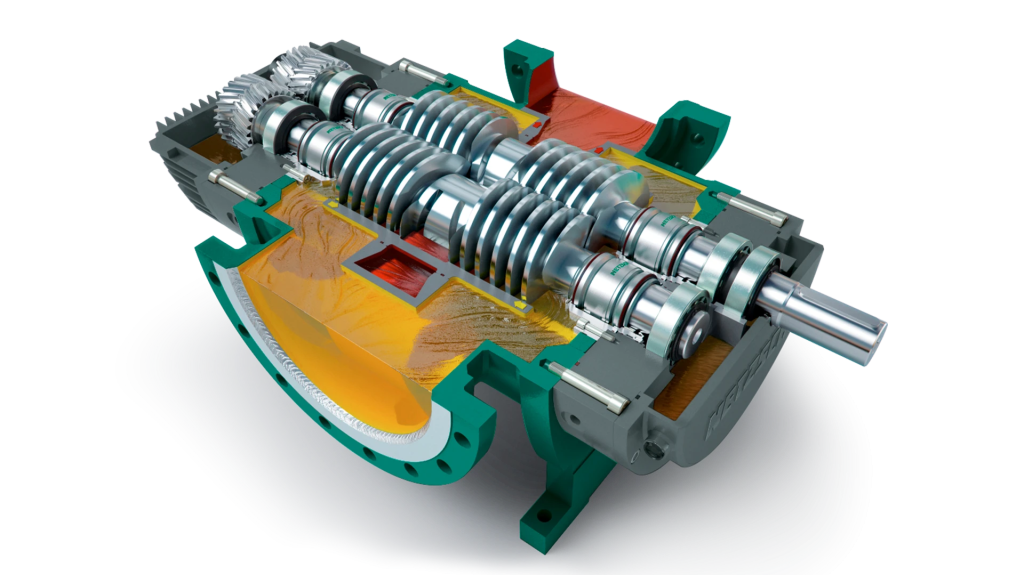

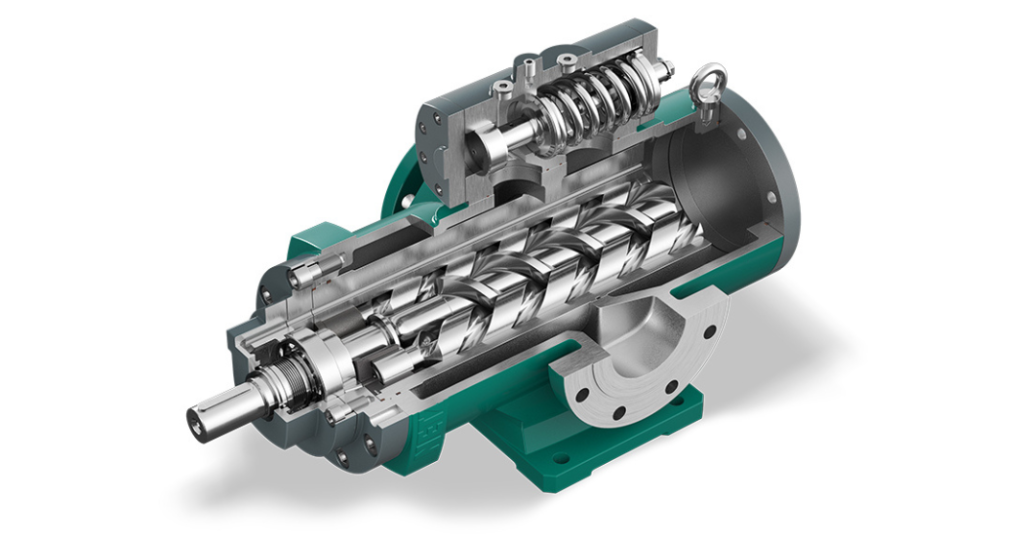

One of the twin-screw, three-screw, and five-screw pumps is an active screw, which is a right-handed convex screw, and the rest are driven screws, which are left-handed concave screws. When the screw rotates, the volume of the suction chamber increases and the pressure decreases. The liquid enters the suction chamber along the suction pipe under the action of the pressure difference between the inside and outside of the pump. As the screw rotates, the liquid in the sealed chamber moves continuously and evenly along the axial direction to the discharge chamber. As the volume of one end of the discharge chamber gradually decreases, the liquid is discharged.

A twin-screw pump is an externally meshed screw pump, which uses two screws that mesh with each other and do not contact each other to pump liquid. The unique structure enables it to realize non-stirring, non-pulsating and stable conveying of various media; because the pump body structure ensures that the pumping liquid is always present in the working element of the pump as a sealing liquid, the twin-screw pump has a strong self-priming ability, and its special design also ensures that the pump has a high suction performance, that is, a very small NPSHr value.

The three-screw pump is mainly composed of a bushing fixed in the pump body, an active screw inserted in the pump cylinder, and two driven screws meshing with it. Since the two driven screws mesh symmetrically with the active screw, the radial force acting on the active screw of the three-screw pump is completely balanced, and the active screw does not bear bending load. The radial force on the driven screw is supported by the pump cylinder bushing along its entire length, and no bearing is required at the outer end, and it basically does not bear bending load. The remarkable features of the three-screw pump are simple structure, small pressure pulsation, stable flow, stable and reliable operation, high speed, low noise, high efficiency, long life, and self-priming ability.

Wide pressure and flow range;

Wide range of types and viscosities of transported liquids;

High speeds can be used because the rotating parts in the pump have low inertia;

Good suction performance and self-priming ability;

Uniform and continuous flow, low vibration and low noise;

Less sensitive to incoming gas and dirt than other rotary pumps;

Solid structure and easy installation and maintenance.

G4 – 45 INLET DESIGN The high-efficiency G4 progressing cavity pump’s 45°inlet lowers friction loss and provides for gentler handling of the product. People Also Ask

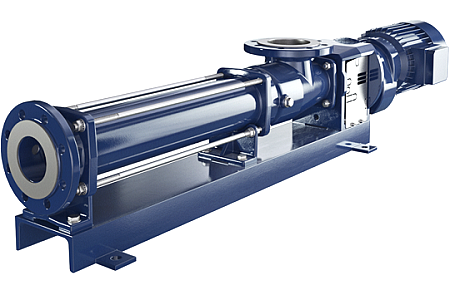

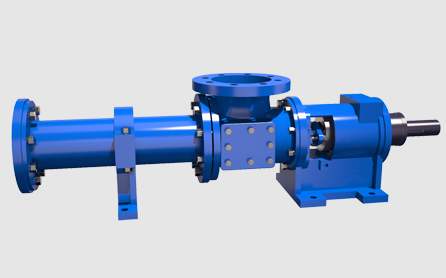

G1 – FLANGED DESIGN Versatile, high performance pump designed to handle a wide range of applications from shear-sensitive chemicals to difficult-to-process slurries and sludges. High-performance 2000 Pumps offer low maintenance, minimal downtime and long service life for low total cost of ownership. People Also Ask

2000WA – CLOSE COUPLED DESIGN The 2000WA close coupled pump is specifically designed for lower pressure, lower flow applications that do not require the full features and benefits of the 2000G1 pump. The 2000WA features a close coupled design that has integral bearings that support the radial thrust loads that can be seen at the…

MXQ MM-Series Pumps MXQ MM-Series pumps are exact duplicates of the Moyno® 2000 series progressive cavity pumps. These pumps are manufactured to handle thrust and radial loads efficiently. Their high quality gear joints and materials of construction create a very robust, reliable option for your application. People Also Ask

MDR – Superior Process Control The MDR range design incorporates an external GA seal arrangement and engineered composite seal housing, lantern, and rotating unit. The only metallic part of the pump that is exposed to the conveyed product is the rotor. This design allows for broad chemical compatibility, increased performance, and decreased maintenance. The patented…

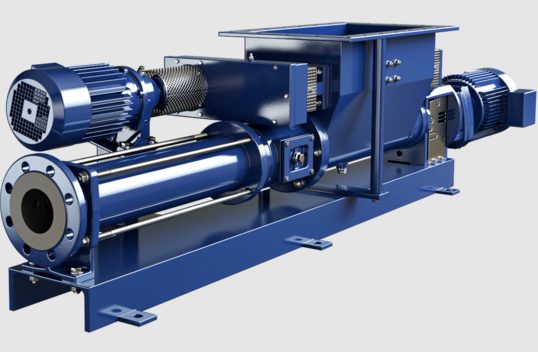

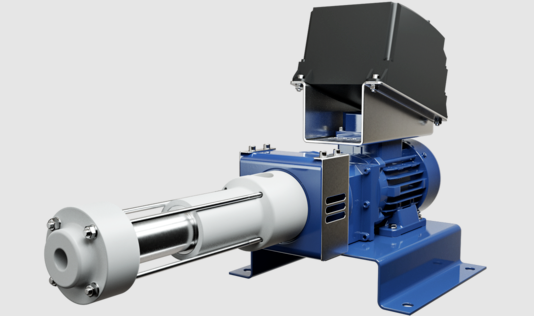

Open Hopper Cavity Pump Introduction Open Hopper Cavity Pump is a type of positive displacement pump that is designed to handle viscous and shear-sensitive materials. It has an open hopper or feeding area which allows for easy loading and unloading of the material being pumped. The pump’s unique design features a rotor that rotates inside…

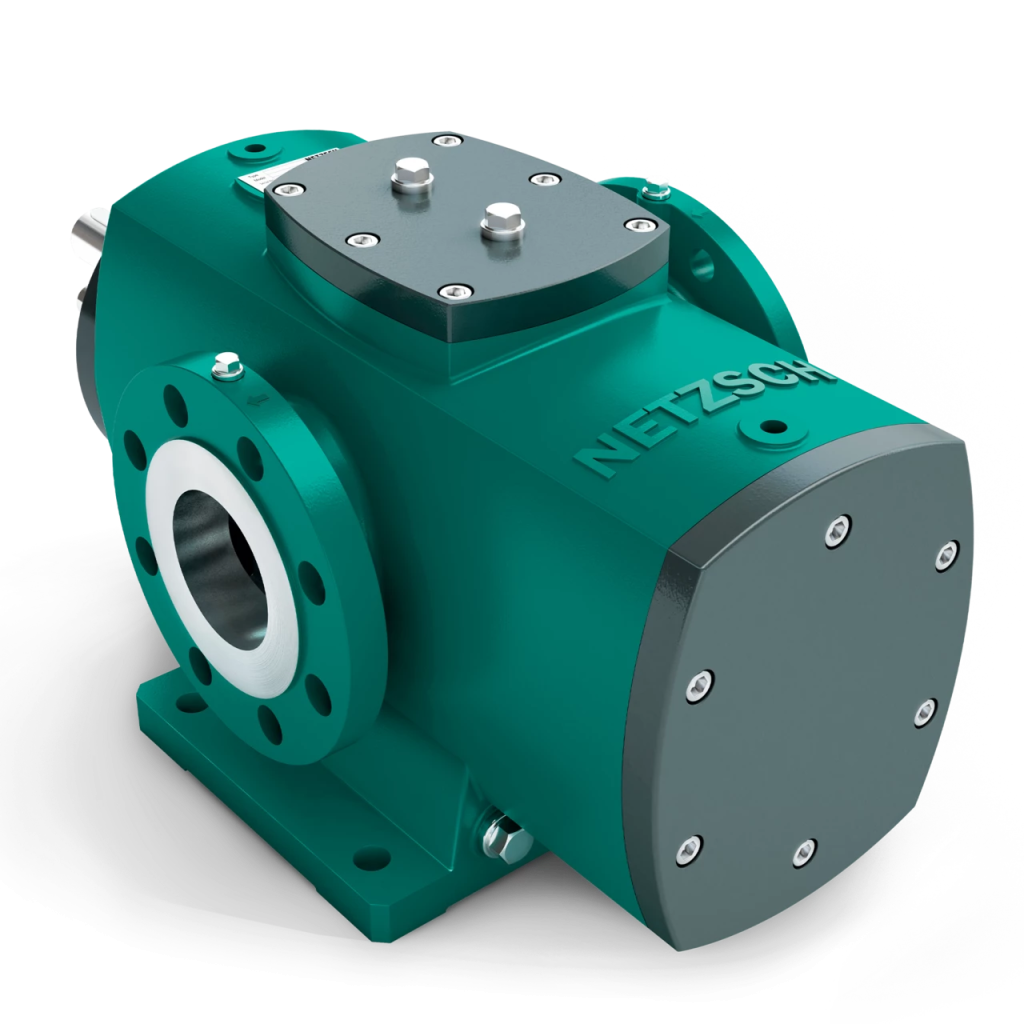

The Description of NETZSCH PUMP Netzsch pump is a type of positive displacement pump that utilizes a progressive cavity design to handle difficult-to-pump fluids with high viscosity, abrasiveness, and shear sensitivity. This type of pump is designed with a helical rotor and stator that create a series of sealed cavities to move fluid through the…

The Description of Pump Hopper A pump hopper is an equipment used in the process of transferring materials from one location to another using a pump. It is designed to receive, store and feed material into the pump system efficiently and safely. The Application of Pump Hopper Pump hoppers are widely used in various industries…

DESIGNED WITH THREADED CONNECTIONS FOR GENERAL METERING APPLICATIONS MD Range progressive cavity pumps are used in virtually all industries for metering and dosing precise quantities. They are particularly good for minimal pulsation conveyance of thin to viscous fluids, as well as corrosive media containing solids. People Also Ask

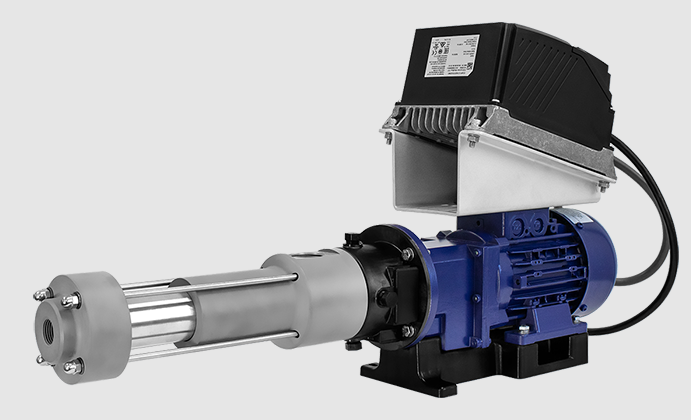

INCORPORATES VARIABLE FREQUENCY DRIVE (VFD) WITH ELECTRONIC PROGRAMMING MODULE (EPM) MEMORY CHIP The Intelligent Metering Pump (IMP) design incorporates a gear reducer and a programmable vector drive in a compact design for precise metering. Metering parameters can be pre-configured on an Electronic Programming Module (EPM) memory chip, making conversion from a previous drive to a…