-

-

-

Pump Screw-PMV Pump

People Also Ask

-

-

Type of Screw Pump-Pumpvv

What is a screw pump? Screw pump is a part of the dry compressed gas transfer pump series. They are positive displacement pumps that use one or more screws to move fluid or water along the screw shaft. These screws interlock to pressurize the fluid and move it into the system. These screws engage each…

-

Screw Pump-Pumpvv

The Description of Screw Pump A screw pump is a type of positive displacement pump that utilizes an intermeshing screw and housing to transfer fluids or viscous substances. The pump consists of two or more screws (also known as rotors) that rotate in opposite directions, creating chambers that trap and move the fluid along the…

-

Netzsch Nm031

Netzsch Nm031 Name:Progressive cavity screw pumpMaterial :304/316L SSCertificate:ISO9001-2016Type:Netzsch typeApplicable industries :Food/Chemical/Paper-making/ Oil/Coal/Shipbuilding/Sewage/ Environmental production/Metallurgy and mining/:Mine drainage/Construction The Netzsch Nm031 Progressive Cavity Pump Parts netzsch pump parts People Also Ask

-

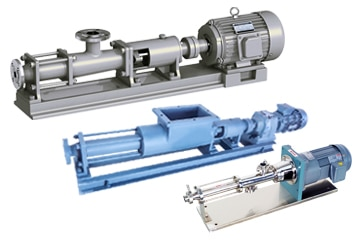

G Type Single Screw Pump

G Type Single Screw Pump Single Screw Pump Operating Principle and Benefits Single screw pump is a type of rotary positive displacement pump that operates based on the positive displacement principle. The pump works by creating sealed cavities through the interference fit of a single-helix metal rotor and a double-helix elastic stator. Due to the…

-

G series single screw pumps

G series single screw pumps Q=0.8-60 m³/h ( 3.52 USGPM – 264 USGPM ) P=0~1.2 Mpa (0~174 psi) CONTACT Single screw pumps are commonly called progressive cavity pumps. They work according to the positive displacement principle. The interference fit of the single-helix metal rotor and the double-helix elastic stator forms sealed cavitites. When the rotor…

progressive cavity screw pump

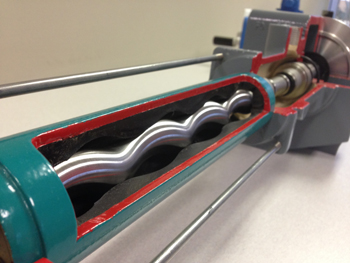

A progressive cavity screw pump is a type of positive displacement pump that utilizes a helical rotor and a stator to move fluids. This design allows for the efficient handling of a wide range of fluids, including viscous, shear-sensitive, and abrasive materials. Below is an overview of the pump’s features, operating principles, applications, and benefits.

1. Key Components

1.1 Rotor

-

- Design:

-

- Helical-shaped and rotates within the stator.

-

- Typically made from durable materials to withstand wear.

1.2 Stator

-

- Design:

-

- Fixed, elastomeric or metal housing that surrounds the rotor.

-

- The inner surface is shaped to form a tight seal with the rotor.

2. Operating Principle

-

- Fluid Movement:

-

- As the rotor turns, it creates a series of sealed cavities between the rotor and stator.

-

- These cavities trap the fluid and move it from the inlet to the outlet, effectively transferring it without pulsation.

-

- Pressure Generation:

-

- The rotation of the rotor generates pressure, allowing the pump to push the fluid through the system.

3. Applications

Progressive cavity screw pumps are widely used in various industries, including:

-

- Food and Beverage:

-

- Ideal for transferring viscous products like sauces, creams, and pastes.

-

- Chemical Processing:

-

- Suitable for handling corrosive and abrasive liquids.

-

- Wastewater Treatment:

-

- Effective in pumping sludge, slurries, and other viscous materials.

-

- Pharmaceuticals:

-

- Used for transferring sensitive compounds that require gentle handling.

-

- Oil and Gas:

-

- Employed to move heavy crude oil and other viscous fluids.

4. Advantages

-

- Versatility:

-

- Capable of handling a wide range of fluid viscosities and types.

-

- Steady Flow Rate:

-

- Provides a continuous and smooth flow, minimizing pulsations.

-

- Self-Priming:

-

- Can handle air and gas within the fluid, making it effective for various applications.

-

- Low Shear:

-

- Gentle handling of fluids prevents damage to sensitive products.

-

- High Efficiency:

-

- Effective in transferring fluids with minimal energy loss.

5. Considerations for Use

-

- Material Compatibility:

-

- Ensure the materials of the rotor and stator are compatible with the fluid being pumped.

-

- Maintenance:

-

- Regular inspection and maintenance are necessary to prevent wear and prolong pump life.

-

- Temperature and Pressure Limits:

-

- Be mindful of the operational temperature and pressure limits to avoid damage.