MOYON SANITARY PUMPS

SANITARY PUMPS Low-shear, non-pulsating Sanitary Pumps transfer shear-sensitive materials with a minimum of turbulence or stress. People Also Ask

Sanitary pumps play a crucial role in various industries, particularly those that require strict hygiene standards. These pumps are designed to transport fluids safely and efficiently while minimizing contamination risks. This article explores the importance, types, applications, and benefits of sanitary pumps.

In industries such as food and beverage, pharmaceuticals, and biotechnology, maintaining cleanliness is paramount. Contaminated fluids can lead to health risks, product spoilage, and regulatory non-compliance. Sanitary pumps are engineered to prevent contamination, making them essential for:

Sanitary pumps come in various types, each suited for specific applications. Understanding these types helps in choosing the right pump for particular needs:

Sanitary pumps find applications across multiple sectors, including:

Investing in sanitary pumps provides numerous advantages:

Sanitary pumps are vital for industries where hygiene is non-negotiable. By ensuring contamination-free fluid transfer, they protect public health and maintain product quality. Selecting the right type of sanitary pump for specific applications can greatly enhance operational efficiency and compliance with health regulations. As industries continue to evolve, the importance of sanitary pumps will only grow, making them indispensable in the quest for safety and quality.

SANITARY PUMPS Low-shear, non-pulsating Sanitary Pumps transfer shear-sensitive materials with a minimum of turbulence or stress. People Also Ask

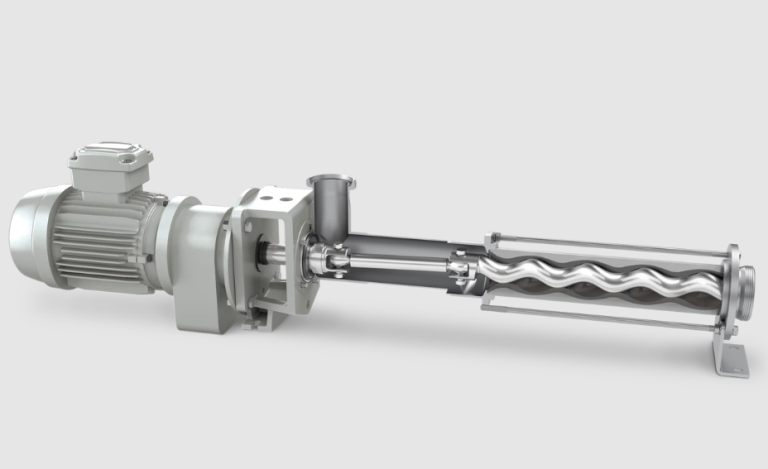

Moyno Sanitary High Pressure Pumps Moyno sanitary high pressure pumps are modified versions of the series 2000 progressive cavity pumps. Suitable for hygienic applications wher high flow rates at high pressure are required to pump high viscosity products. Pumps meet 3A and BISSC standards and also feature CIP capabilities. People Also Ask

Compliant and Efficient of NEMO Sanitary Pumps The NEMO sanitary pumps meet strict regulatory standards, including use of Food and Drug Administration (FDA) compliant materials and design in accordance with food application specifications to prevent the product from lodging in areas where bacteria may form. NEMO sanitary pumps are designed, produced, and inspected in accordance…

NEMO® BH Sanitary Advanced Pump in Compact Block Design NEMO® BH Sanitary Advanced Pump The NEMO BH hygienic pump in compact block design is used for hygienic applications in the food,pharmaceutical, cosmetic and chemical/biochemical industries because of its optimal process characteristics. People Also Ask