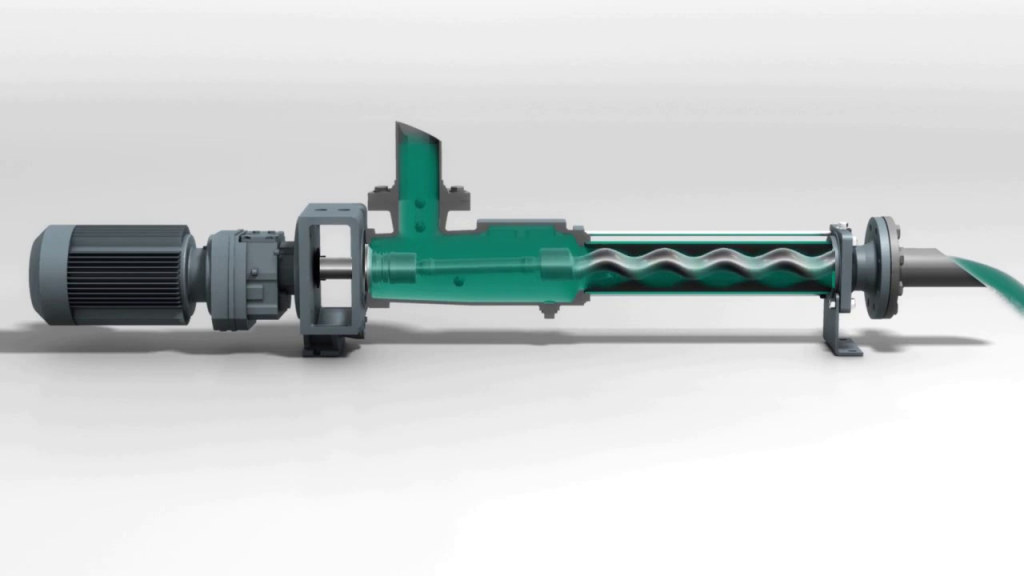

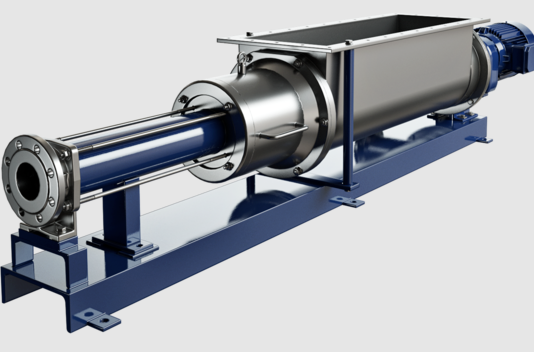

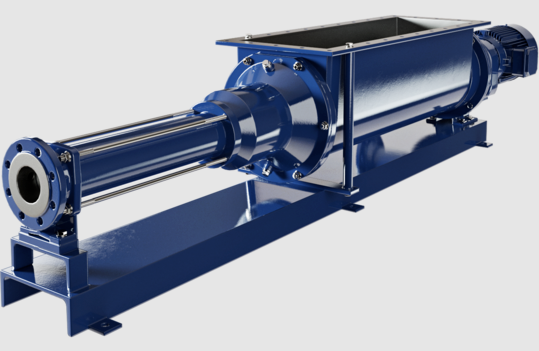

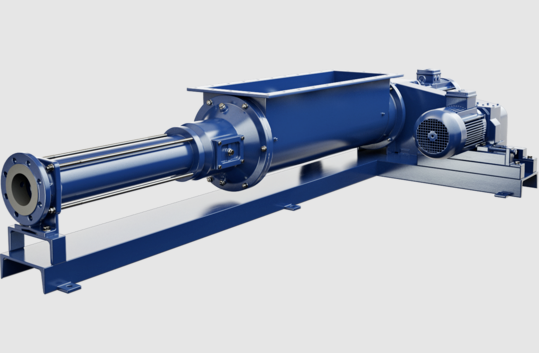

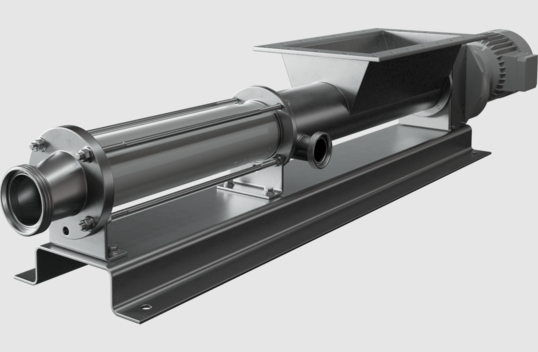

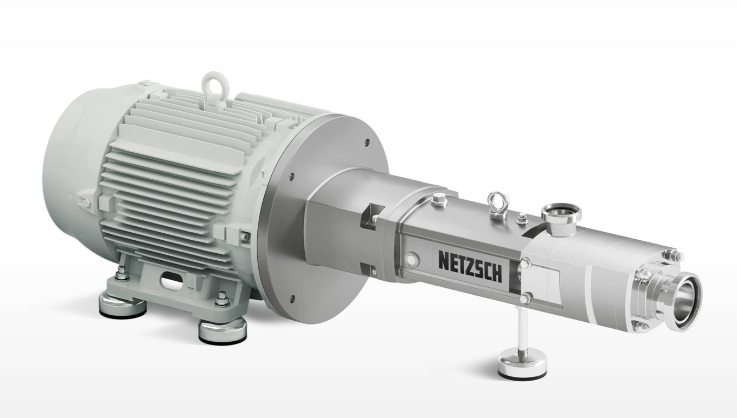

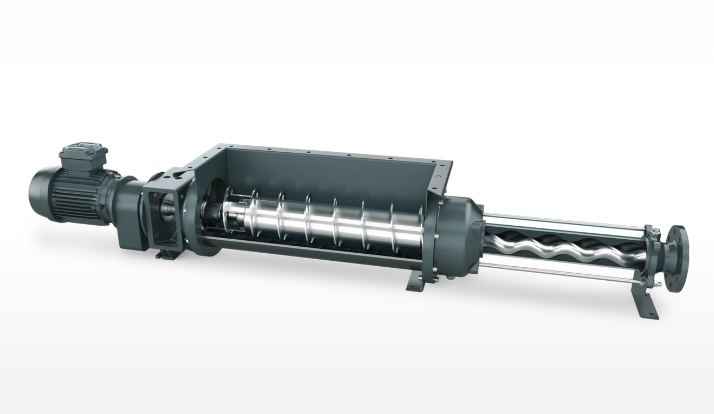

SEEPEX BTVE – WITH ROBUST FULL SCREW

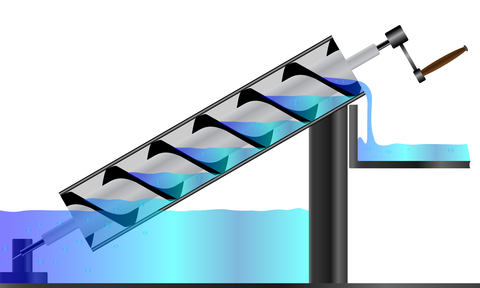

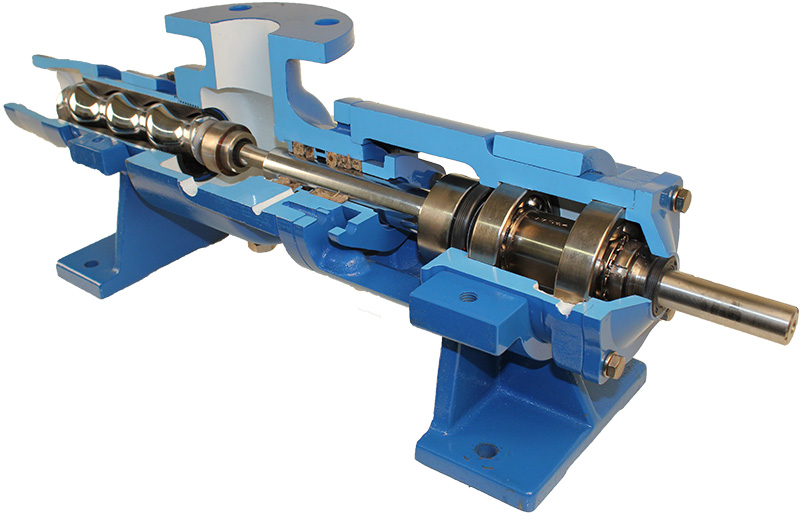

FROM HIGHLY VISCOUS TO SEMI-SOLID BTVE hopper pumps from SEEPEX provide the ability to transport dewatered sludge with a dry matter content of up to 30%. A large, rectangular intake hopper with screw conveyor allows them to easily be fed with highly viscous and semi-solid products with no tendency towards bridging. A roller-mounted sliding compression…