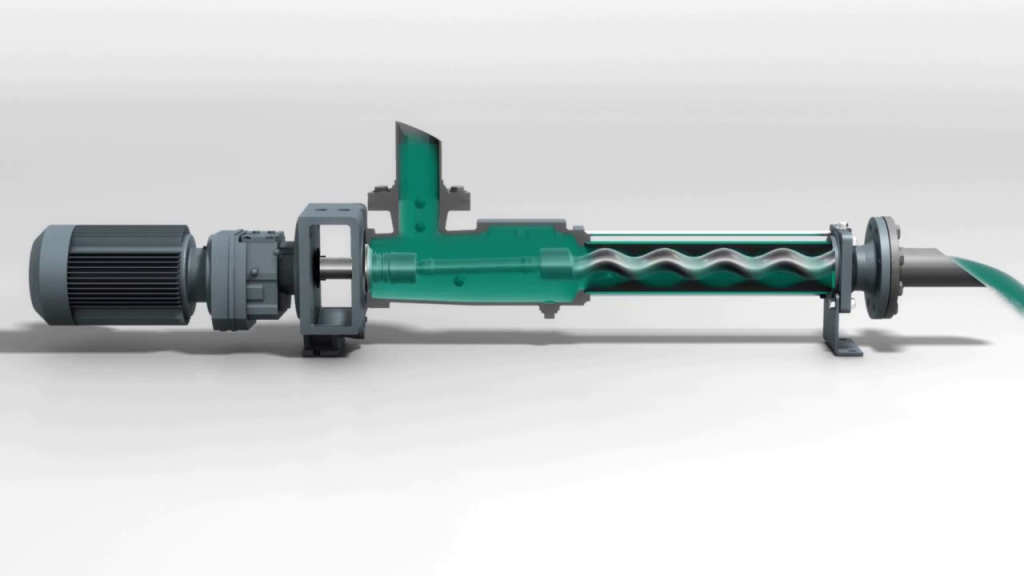

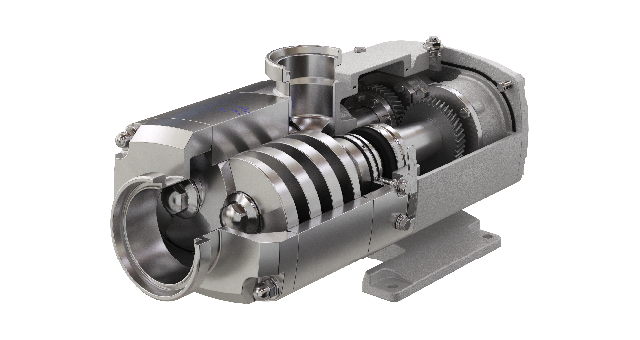

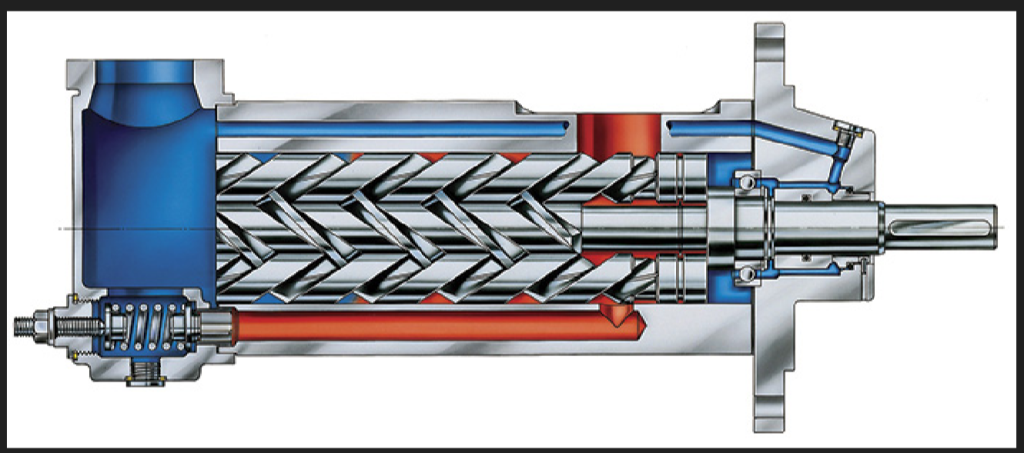

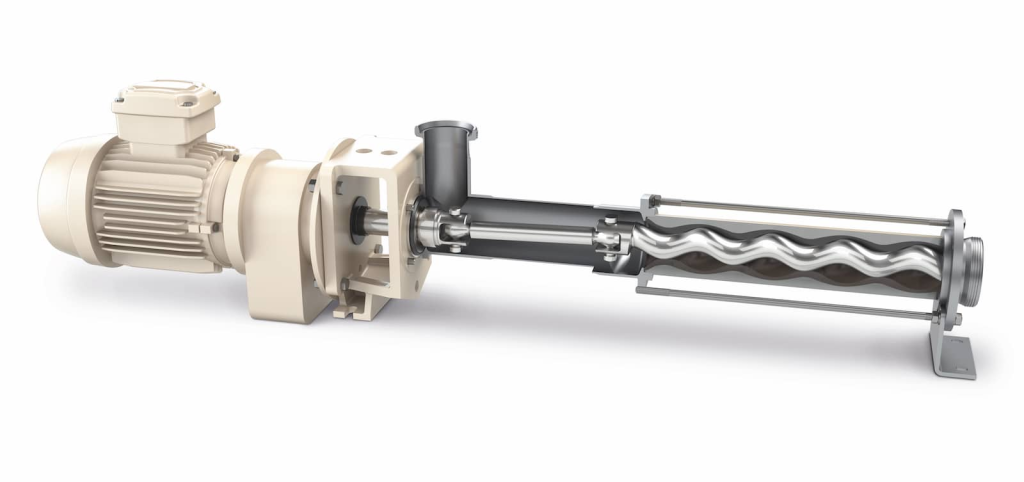

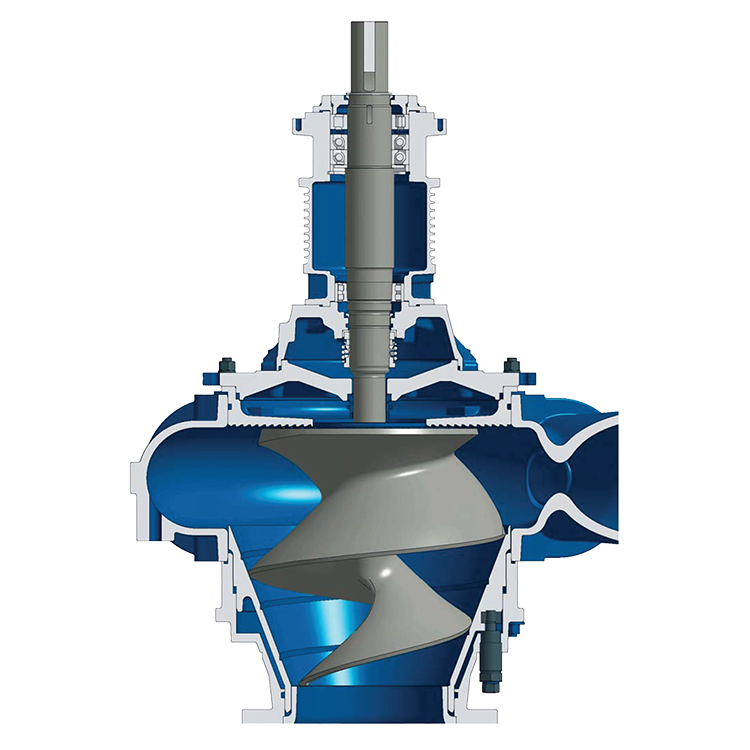

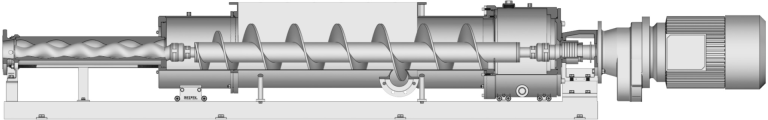

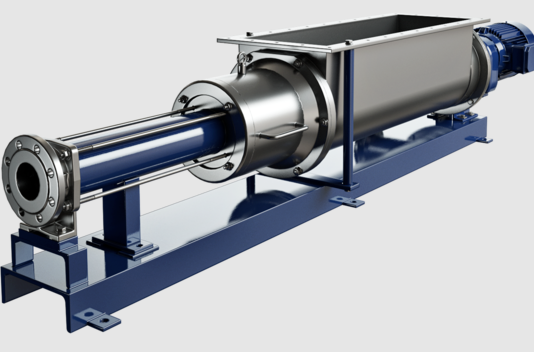

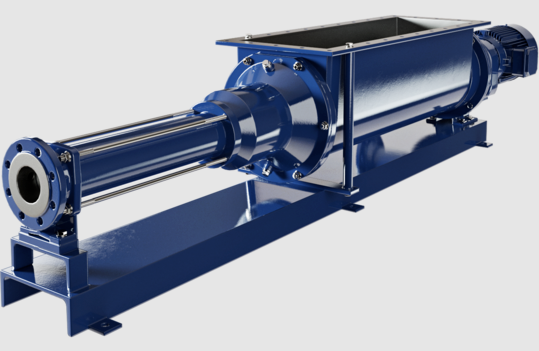

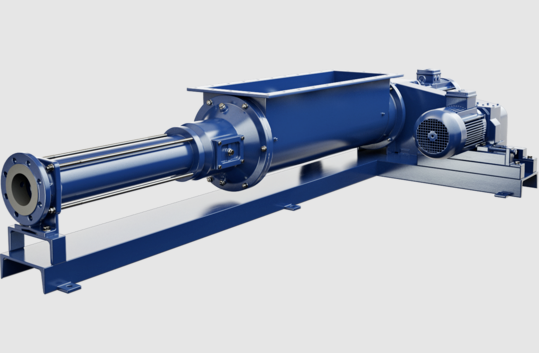

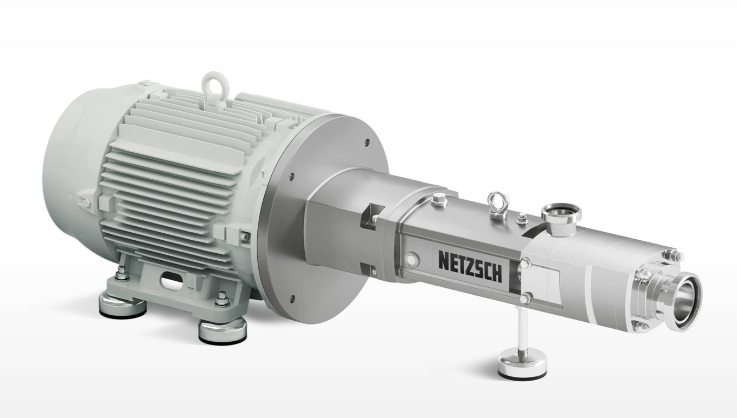

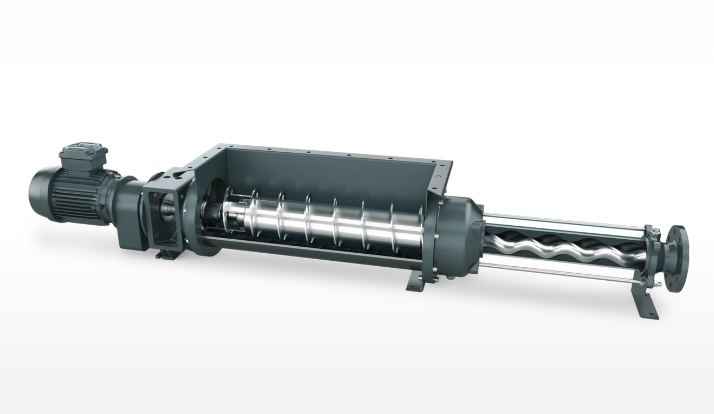

Screw Pump Diagram

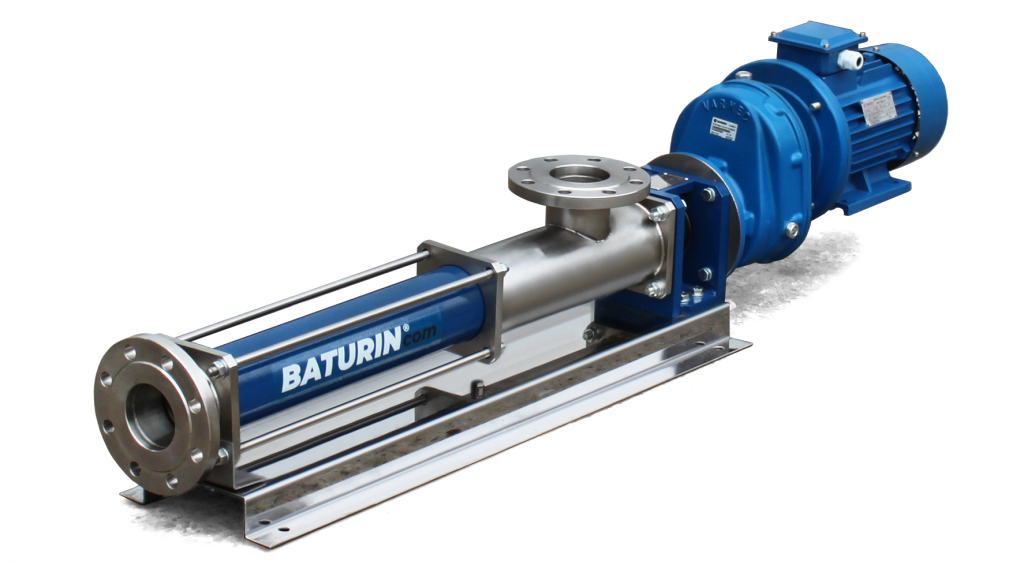

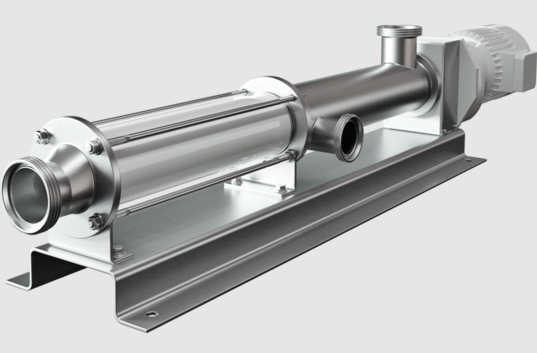

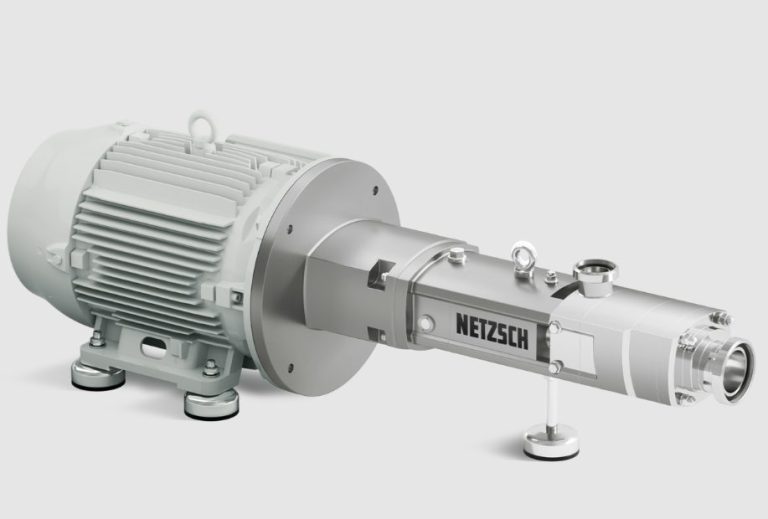

Introduction to Screw Pump Diagram. A screw pump diagram is a schematic representation of the working principle and components of a screw pump. Screw pumps are positive displacement pumps that use rotating screws to move fluids or slurries through a system. They are widely used in various industries due to their ability to handle high…