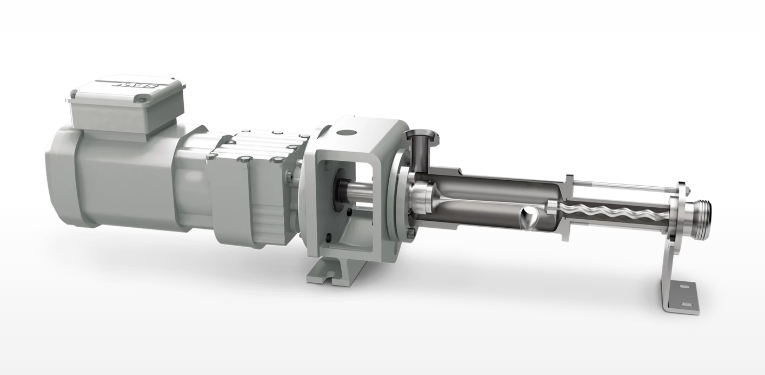

Working Principle

The working principle of the BN15-6L rotor is based on the fundamental operation of screw pumps. Driven by a motor, the rotor rotates, creating a sealed chamber between the rotor and the stator that transports the medium from the inlet to the outlet.

- Conveying Process

As the rotor spins, the medium is progressively compressed in the space between the rotor and the stator, generating pressure. This continuous pressure allows the medium to move smoothly forward. The design of the BN15-6L rotor ensures stability and uniformity in fluid transport, preventing bubble formation or pulsation, which enhances operational efficiency.

- Strong Adaptability

The BN15-6L rotor can accommodate a variety of media, including viscous liquids and fluids containing solid particles. This versatility makes it suitable for applications in food, chemical, and wastewater treatment industries.

Characteristics of the BN15-6L Rotor

1. Superior Design

The BN15-6L rotor features a carefully considered design that ensures stable performance across various working environments. Its compact structure and high-quality materials guarantee durability and corrosion resistance.

2. High Efficiency

This rotor utilizes advanced fluid dynamics principles, allowing for smoother fluid flow within the rotor. With its optimized shape, the BN15-6L can achieve higher transport efficiency while reducing energy consumption.

3. Strong Adaptability

Whether transporting high-viscosity or low-viscosity fluids, the BN15-6L rotor excels in performance. Its flexible adaptability makes it a preferred choice for a variety of industrial applications.

Application Fields

The BN15-6L rotor has found extensive use in various industries due to its superior performance.

Food and Beverage Industry

In the food and beverage sector, hygiene and safety are paramount. The BN15-6L rotor efficiently handles various food liquids while meeting strict sanitary standards. Its corrosion-resistant material also ensures durability during high-temperature sterilization processes.

Chemical Industry

The chemical industry often requires the transport of complex chemical media. With its robust adaptability and chemical resistance, the BN15-6L rotor has become a preferred choice in many chemical plants. Whether dealing with acidic, alkaline, or other specialty chemicals, the BN15-6L rotor can deliver effective transport.

Wastewater Treatment

In wastewater treatment processes, the BN15-6L rotor plays a critical role. It can manage wastewater containing solid particles, ensuring smooth discharge and improving the overall efficiency of the treatment system.

Maintenance Practices

To ensure the long-term stable operation of the BN15-6L rotor, regular maintenance is essential.

1. Regular Inspections

Conduct routine inspections of the rotor and its components for wear and tear. Timely replacement of damaged parts can prevent potential failures.

2. Cleaning Maintenance

Keep the rotor clean to avoid the accumulation of impurities that could hinder its performance. Use appropriate cleaning agents to prevent damage to the materials.

3. Lubrication

Apply suitable lubricating oil to the rotor to ensure smooth operation and reduce friction wear, thereby extending its lifespan.

4. Temperature Monitoring

Monitor the operating temperature of the rotor, as excessive heat can affect its performance and longevity. Implement cooling measures as necessary to maintain operation within a reasonable temperature range.

people also ask

Send Your Enquiry :