Food Grade Progressive Cavity Pumps

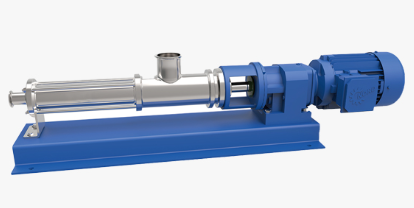

Progressive cavity pumps play a crucial role in the food and beverage industry, providing efficient and reliable solutions for transferring various types of viscous fluids. These pumps are designed to meet stringent hygiene standards while ensuring smooth operation.

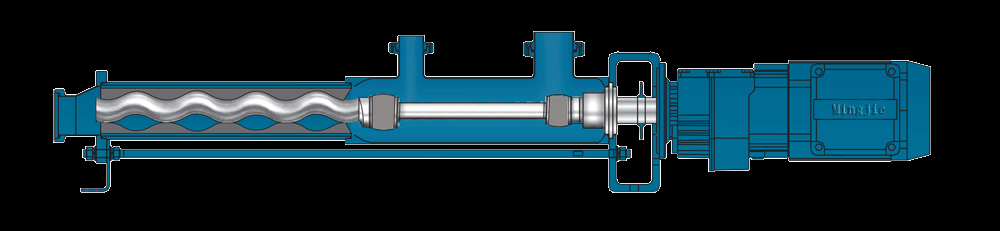

What Are Progressive Cavity Pumps?

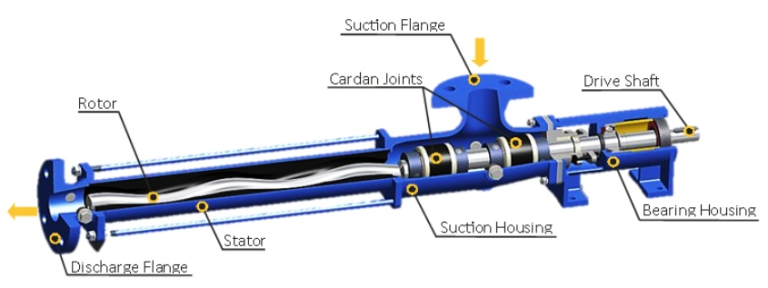

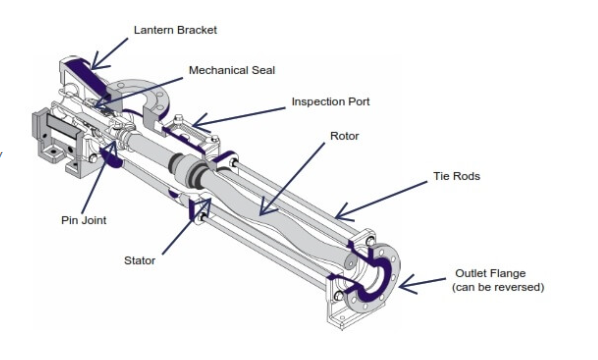

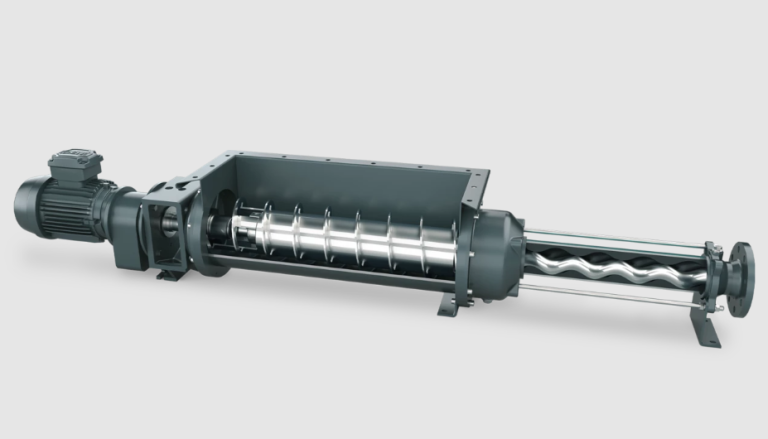

Progressive cavity pumps consist of a helical rotor and a stator. The rotor rotates within the stator, creating cavities that transport fluids. This design allows for gentle handling of delicate products, making them ideal for food applications.

Key Features

- Hygienic Design

Food grade progressive cavity pumps are constructed with materials that comply with health regulations. Stainless steel and other non-corrosive materials minimize contamination risks. - Gentle Product Handling

The nature of the pumping action prevents shear and degradation, making these pumps suitable for sensitive products such as creams, sauces, and purees. - Versatility

These pumps can handle a wide range of viscosities, from thin liquids to thick pastes. This versatility allows for use in various applications, including dairy, meat processing, and beverage production. - Self-Priming Capability

Progressive cavity pumps can easily self-prime, making them effective for transferring fluids from tanks or containers without additional equipment.

Applications in the Food Industry

Progressive cavity pumps are used in numerous applications across the food sector, including:

- Dairy Processing

They are ideal for transporting milk, yogurt, and cheese mixtures without compromising quality. - Beverage Production

These pumps efficiently handle juices, syrups, and other liquid ingredients, maintaining flavor and consistency. - Sauces and Dressings

The gentle pumping action ensures that sauces and dressings retain their texture and taste during transfer. - Meat and Poultry Processing

They are effective for moving marinades, pastes, and other viscous mixtures in meat production.

Advantages of Using Food Grade Progressive Cavity Pumps

- Enhanced Product Quality

The gentle handling of products ensures that flavors and textures remain intact, contributing to superior quality. - Reduced Downtime

With their reliable performance and self-priming capabilities, these pumps minimize operational interruptions. - Easy Maintenance

Many models are designed for easy disassembly and cleaning, facilitating compliance with hygiene standards.

Conclusion

Food grade progressive cavity pumps are indispensable in the food and beverage industry. Their unique design, coupled with hygienic materials, makes them a perfect choice for transferring a variety of products. By ensuring gentle handling and maintaining product integrity, these pumps contribute to the overall quality and safety of food products. As the industry continues to evolve, the importance of reliable and efficient pumping solutions will only increase, making progressive cavity pumps a vital component in modern food processing.

Send Your Enquiry :