[wpseo_breadcrumb]

DESIGNED TO IMPROVE INTAKE EFFICIENCY ON HIGHLY VISCOUS MEDIA

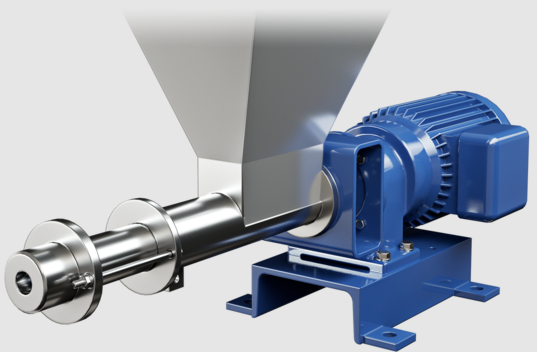

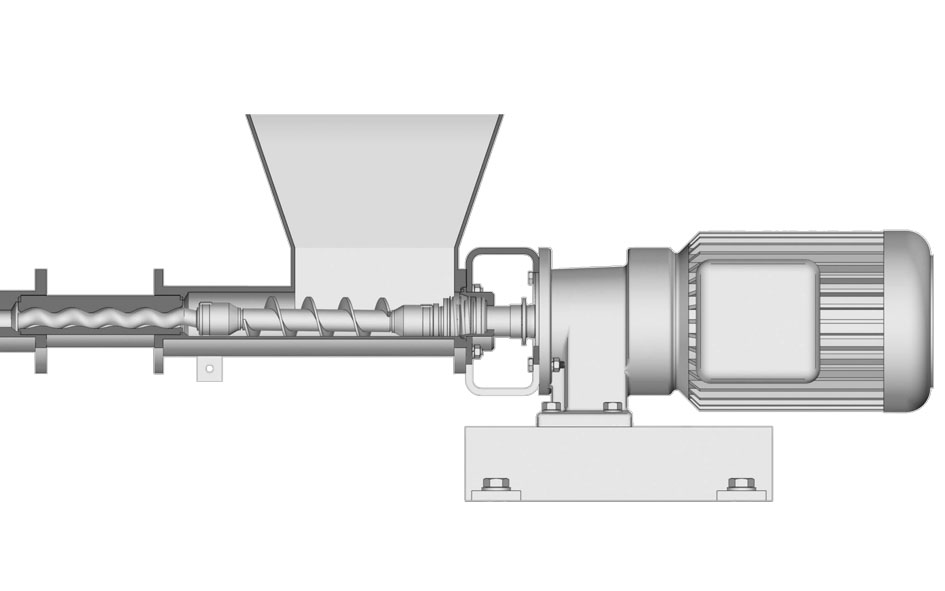

SEEPEX MDT range pumps are used to convey highly viscous media such as peanut butter, molasses, resins, and other media with low flowability. The open hopper on the pump directs media to the auger feed screw on the coupling rod which feeds the media into the rotor and stator.

Description of SEEPEX MDT – Open Hopper Metering Pump

The SEEPEX MDT – Open Hopper Metering Pump offers numerous benefits for a wide range of applications. Its unique open hopper design allows for efficient handling of solids and highly viscous liquids, while its positive displacement pumping action ensures precise and consistent flow rates. The pump’s modular design makes it easy to maintain and repair, reducing downtime and ensuring reliable operation. It is available in a variety of materials, providing flexibility for use with corrosive and abrasive fluids. In addition, the SEEPEX MDT pump is equipped with a range of safety features for added peace of mind, including dry run protection and overload protection. It is also highly customizable, with a range of motor options and accessories available to suit specific application requirements. Overall, the SEEPEX MDT – Open Hopper Metering Pump is a versatile and reliable pump that can offer significant benefits for many industries, from improved process efficiency to cost savings and reduced maintenance requirements.

Application of SEEPEX MDT – Open Hopper Metering Pump

The SEEPEX MDT – Open Hopper Metering Pump is a versatile pump that can be used in a variety of applications. Its unique design allows for the easy and precise metering of a wide range of fluids, from abrasive slurries to highly viscous liquids.

One common application of the SEEPEX MDT is in the chemical industry, where it is used to accurately dose chemicals into processes such as wastewater treatment or chemical manufacturing. The open hopper design of the pump allows for efficient handling of solids, making it ideal for handling chemical powders or granules.

Another application of the SEEPEX MDT is in the food industry, where it can be used to pump highly viscous materials such as tomato paste or peanut butter. The pump’s gentle pumping action ensures that the integrity of the product is maintained while providing accurate dosing.

Overall, the SEEPEX MDT – Open Hopper Metering Pump is a reliable and versatile pump that can be used in a wide range of industries and applications.

Energy and time savings

Compression zone increases capacity of conveying chamber resulting in process time and energy savings

No vapor locking

Cavity design allows for conveyance of liquids, solids, and gases

Ease of operation

Valveless flow control for ease of operation

Performance efficiency

Low slip (internal back flow) provides performance efficiency and less wear on components

Easy maintenance

Simple and predictive maintenance due to minimal components

People Also Ask

Send Your Enquiry :