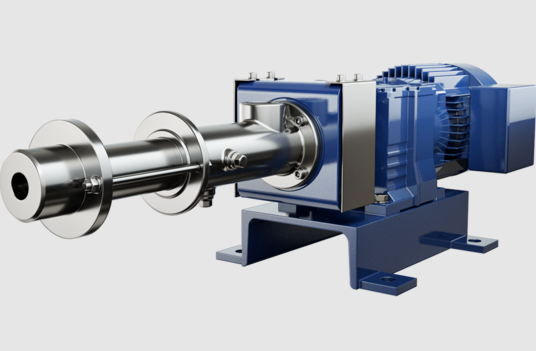

DESIGNED WITH THREADED CONNECTIONS FOR GENERAL METERING APPLICATIONS

MD Range progressive cavity pumps are used in virtually all industries for metering and dosing precise quantities. They are particularly good for minimal pulsation conveyance of thin to viscous fluids, as well as corrosive media containing solids.

Precision Dosing with SEEPEX MD Metering Pump

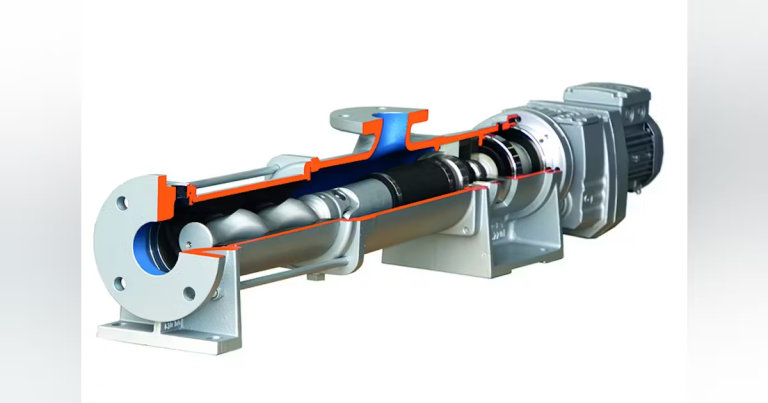

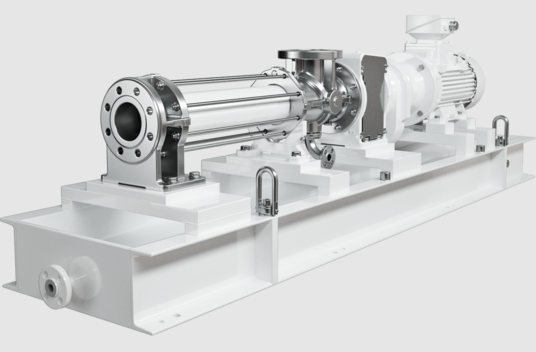

The SEEPEX MD Metering Pump is the perfect solution for precise metering and dosing applications. With its robust design and innovative technology, this pump ensures accurate and reliable performance every time. Its modular construction allows for easy maintenance and repair, making it a cost-effective choice for any industry.

The MD Metering Pump offers a wide range of flow rates and discharge pressures, making it highly versatile and adaptable to different applications. It features a simple and intuitive interface that allows for easy operation and control.

Whether you need to dose chemicals, additives, or other materials with precision, the SEEPEX MD Metering Pump has got you covered. Trust its accuracy and consistency for your most demanding metering and dosing needs.

Precision Dosing Applications for SEEPEX MD Metering Pump

The SEEPEX MD Metering Pump is ideal for a variety of precision dosing applications across different industries. Its accurate and reliable performance ensures that the right amount of material is always delivered, minimizing waste and improving process efficiency.

In the chemical industry, the MD Metering Pump can be used for precise dosing of chemicals into production processes or wastewater treatment systems. It is also suitable for pharmaceutical applications where precise dosing of active ingredients is critical.

Other applications include food and beverage processing, where the pump can be used for dosing ingredients such as flavors, colors, and preservatives. It is also suitable for water treatment applications, where it can be used for adding chemicals to adjust pH levels or disinfect water.

Overall, the SEEPEX MD Metering Pump offers unparalleled precision and reliability for a wide range of dosing applications, making it a valuable asset for any industry.

Economical

Reduced costs due to inexpensive rotating unit

No vapor locking

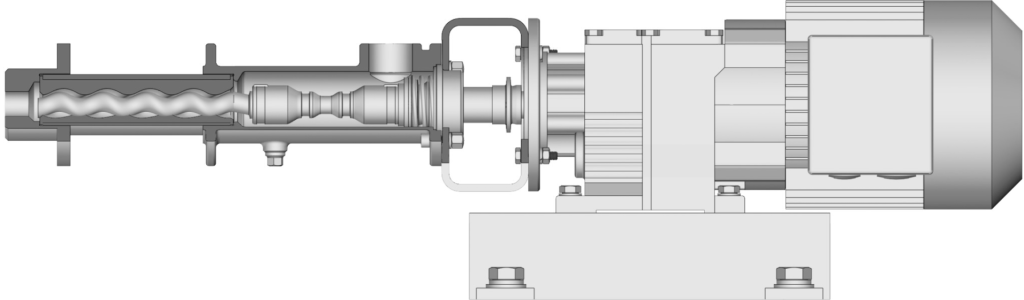

Cavity design allows for conveyance of liquids, solids, and gases

Ease of operation

Valveless flow control for ease of operation

Performance efficiency

Low slip (internal back flow) provides performance efficiency and less wear on components

Easy maintenance

Simple and predictive maintenance due to minimal components

Durable

High corrosion resistance due to the variety of components made of Hastelloy C or Titanium

Exact Dosing

High dosing accuracy (deviation only +/- 1%)

People Also Ask

Send Your Enquiry :