Progressive Cavity Metering Pump-Pumpvv

Description to Progressive Cavity Metering Pump

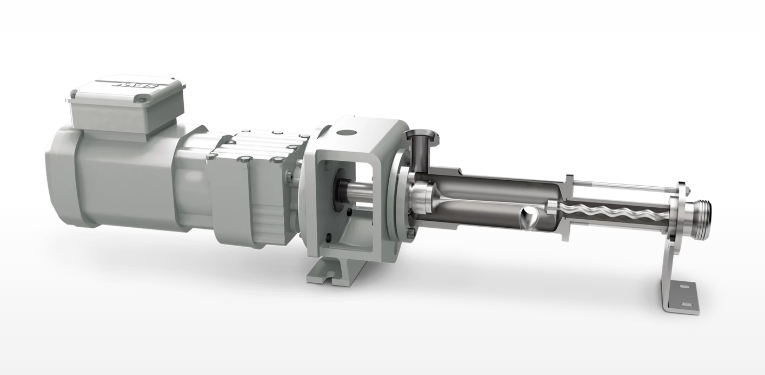

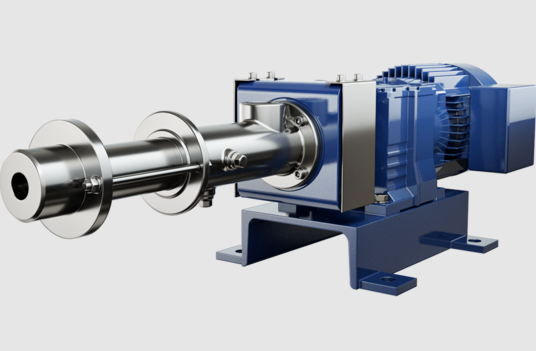

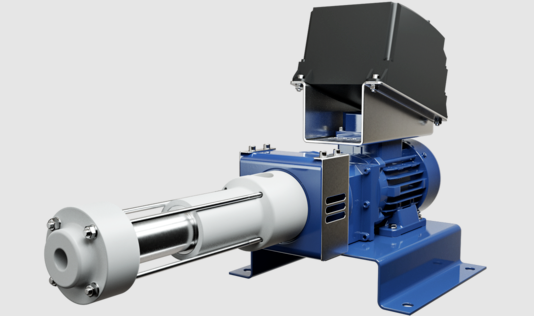

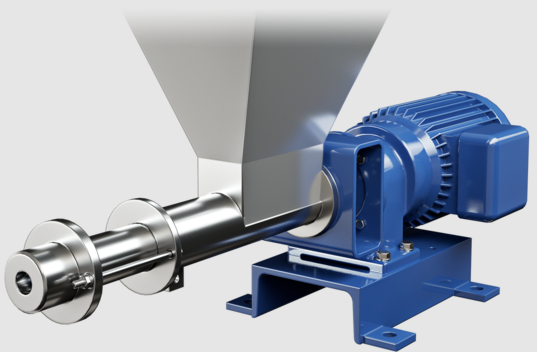

The Progressive Cavity Metering Pump, also known as a PC pump, is a versatile and efficient pump used for accurate and precise metering of fluids. It is commonly used in various industries where precise dosing or controlled flow rates are required.

The Progressive Cavity Metering Pump operates on a positive displacement principle, which means it delivers a consistent volume of fluid with each revolution of the pump’s rotor. This makes it ideal for applications that demand accurate and repeatable dosing, even under varying pressure conditions.

The Working Principle of Progressive Cavity Metering Pump

The pump consists of a helical rotor and a stator, which are designed to create a series of sealed cavities. As the rotor rotates within the stator, the cavities progress from the suction side to the discharge side, effectively pushing the fluid forward. This progressive movement ensures a smooth and pulsation-free flow.

Progressive Cavity Metering Pump Features and Benefits

- Accurate and consistent dosing: The positive displacement design ensures precise and repeatable metering, minimizing errors and waste.

- Wide range of viscosities: The PC pump can handle fluids with a wide range of viscosities, from thin liquids to highly viscous substances.

- Self-priming and gentle handling: The pump is capable of self-priming, eliminating the need for additional priming equipment. It also handles shear-sensitive and abrasive fluids with minimal damage.

- Low pulsation and smooth flow: The design of the pump minimizes pulsation, resulting in a smooth and continuous flow.

- Easy maintenance: The pump’s simple construction allows for easy disassembly and maintenance, reducing downtime and operational costs.

Application of Progressive Cavity Metering Pump

- Chemical dosing and injection

- Food and beverage processing

- Pharmaceutical and biotechnology

- Oil and gas

- Water and wastewater treatment

- Cosmetics and personal care

Send Your Enquiry :