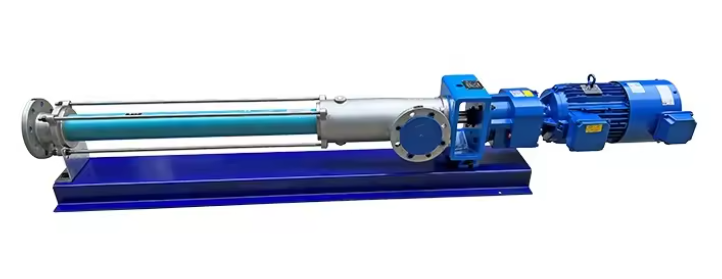

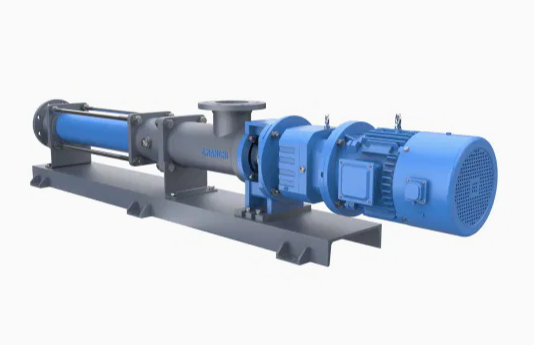

Netzsch pump parts are components and accessories designed specifically for Netzsch pumps. These parts play a vital role in maintaining pump performance and can be replaced as needed to ensure continued efficiency.

What are the parts?

The parts of NETZSCH pumps include rotors, stators, drive shafts, connecting rods, universal joints, mechanical seals/packing seals, etc.

Various applications of Netzsch pump parts:

Rotor and stator:

As the core components of the pump, the rotor and stator directly determine the working performance of the pump. Rotor and stator combinations of different materials and structures are suitable for different media and working conditions.

For example, for high-viscosity fluids, rotors and stators made of stainless steel or special alloys can be selected; for highly corrosive media, parts made of ceramic or hard alloy can be selected.

Seals:

Seals can be in various forms, such as mechanical seals, dynamic seals, etc., to prevent leakage of media in the pump.

The material and structure of the seal must match the working medium. For example, special high-temperature and corrosion-resistant sealing materials are required for high-temperature or corrosive media.

Bearings:

The bearings are responsible for supporting the rotor of the pump to ensure that the pump shaft runs smoothly and reliably.

Depending on different working conditions, Netzsch pumps can use rolling bearings, sliding bearings or combined bearings.

Motors:

Netzsch pumps are usually driven by three-phase asynchronous motors or servo motors. The power and speed of the motor must match the performance of the pump.

For explosive or flammable environments, explosion-proof motors can also be selected.

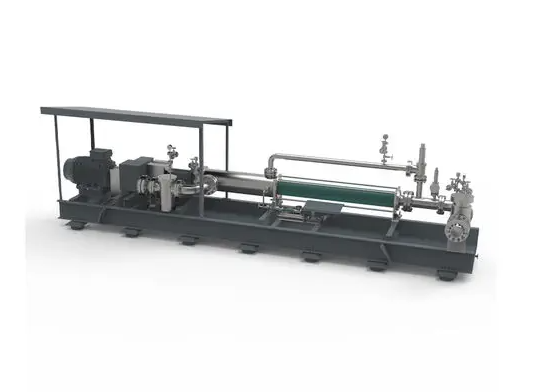

Control system:

Netzsch pumps can be equipped with automatic control systems based on PLC or single-chip microcomputers to monitor and control the operating status of the pump.

The control system can realize automatic adjustment of pump flow, pressure, speed and other parameters to improve the stability of the process.

In general, the selection of Netzsch pump parts needs to be comprehensively considered according to specific process requirements and working environment to ensure the reliable operation of the pump.

People Also Ask

Send Your Enquiry :