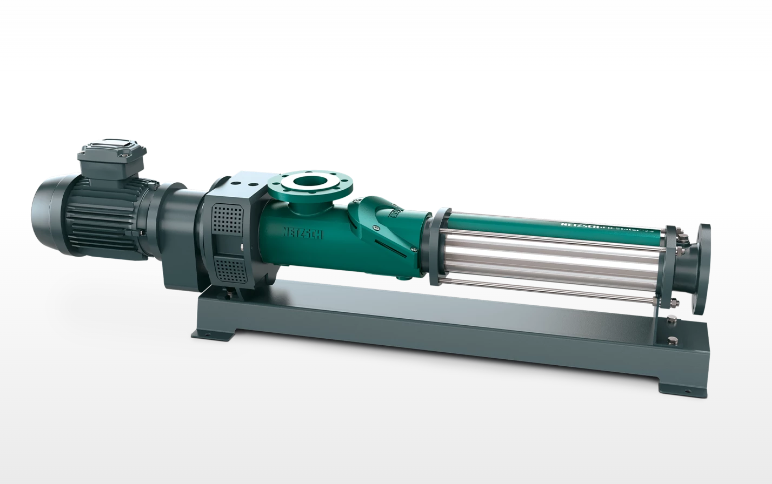

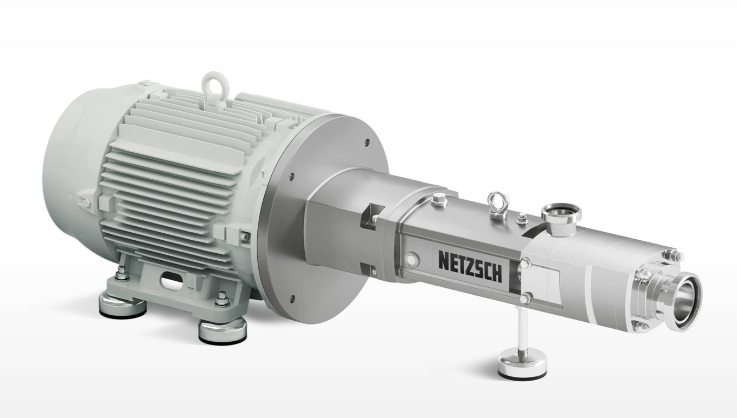

NM038BY01L06B is a compact and versatile industrial screw pump

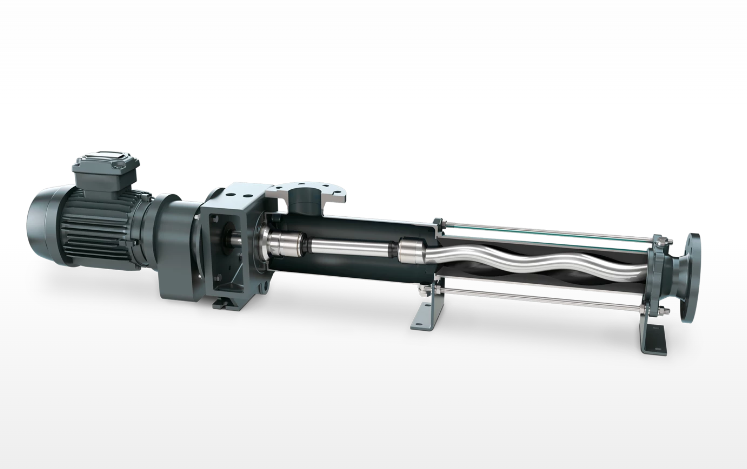

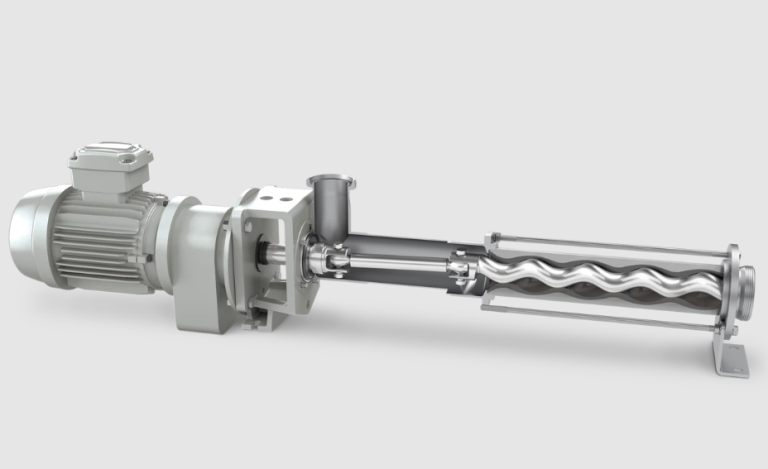

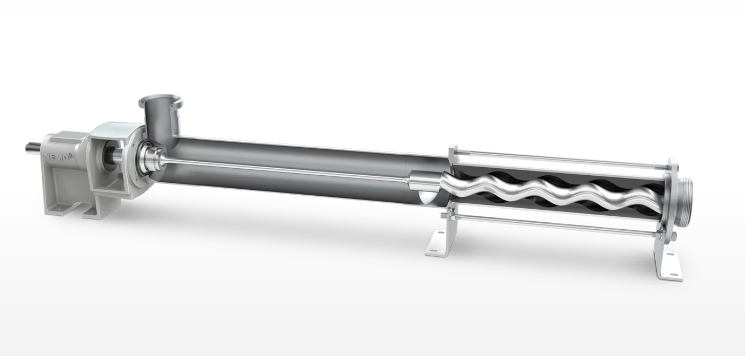

The NM038BY01L06B features a cast iron housing that provides good mechanical strength and wear resistance. The pump’s rotor and stator are made of high-quality materials to ensure long service life and efficient operation. The rotor has a spiral design that produces a smooth and continuous flow of the medium.

The NETZSCH NM038BY01L06B screw pump is a rugged and reliable industrial pump

A key feature of the NM038BY01L06B is its compact size. Due to its small footprint, this screw pump can be easily integrated into a variety of industrial equipment and systems. This makes it a popular choice for space-constrained applications, such as mechanical equipment, process equipment, and mobile hydraulic systems.

In terms of performance, the NM038BY01L06B has a maximum flow rate of up to 38 l/min and a maximum operating pressure of 10 bar. The pump operates in a wide temperature range of -20°C to 100°C, making it suitable for a wide range of environmental conditions.

The NM038BY01L06B is designed with easy maintenance in mind. The pump’s modular construction allows for quick and easy disassembly for inspection, cleaning, and replacement of wear parts. This helps reduce downtime and maintenance costs, and improves overall system reliability and efficiency.

The NM038BY01L06B is compatible with a wide range of fluids, including lubricating oils, hydraulic oils, and mild chemicals. This versatility makes it suitable for a wide range of industrial applications, such as machine tool lubrication, hydraulic power transmission, and liquid delivery systems.

| Model | NM038BY01L06B | Flange Hole Spacing | 70 mm |

| Pump Body Material | Cast Iron | Flange Hole Diameter | 11 mm |

| Rotor Material | Carbon Steel | Flange Outer Diameter | 11 mm |

| Bearing Material | Bearing Steel | Working Pressure | Maximum 10 bar |

| Pump Mounting | Flange-type | Flow Rate Range | 1.5 – 38 L/min |

| Axial Length | 180 mm | Speed Range | 600 – 1500 rpm |

| Weight | About 16 kg | Power | 0.75 – 3 kW |

Screw pumps operate using two counter-rotating screw rotors which are engineered so that they rotate “towards each other”. This traps the gas in the space between the “screws” of their rotors. As the screws rotate, this trapped volume decreases which not only compresses the gas but moves it towards the exhaust.

Chemical Industry

This screw pump model is suitable for the transportation of various chemical raw materials, intermediates, and chemicals, such as acids, alkalis, solvents, emulsions, and other viscous fluids. Its excellent corrosion resistance allows it to perform well even under harsh chemical process conditions.

Food Industry

The NM038BY01L06B screw pump is applicable for the handling of food and beverage products, such as dairy products, sauces, and syrups, which have high viscosity. Its hygienic design and non-contaminating properties ensure food safety.

Pharmaceutical Industry

This pump model is widely used for the transportation of pharmaceutical raw materials and intermediates, including sustained-release liquids, ointments, and suspensions. Its outstanding cleanliness and precise metering capabilities meet the strict requirements of the pharmaceutical industry.

People Also Ask

Send Your Enquiry :