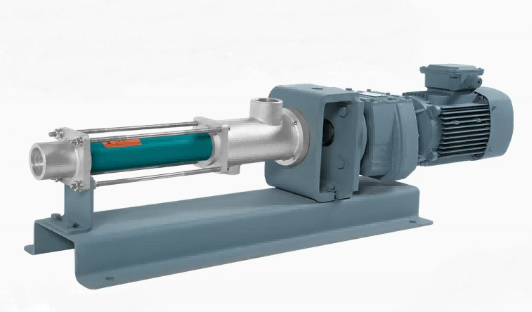

The NM series pump is compact, easy to maintain and has low operating costs. It provides bidirectional flow proportional to speed, ensuring efficient performance. It has excellent self-priming ability and strong discharge capacity, providing continuous, low-pulsation transmission, suitable for mining and media applications with various pressures and viscosities.

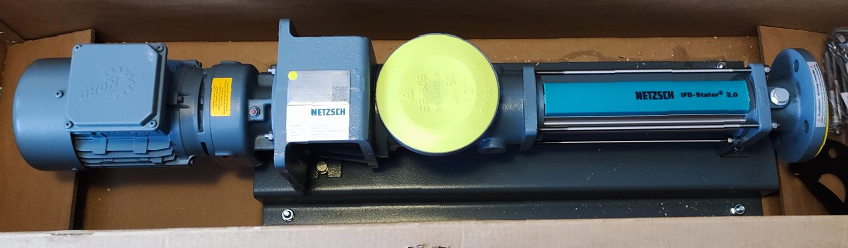

As a positive rotation screw pump, Netzsch NM031BY01L06B is widely used in food, pharmaceutical, chemical and other industries, and can accurately and reliably convey various types of high-viscosity, heat-sensitive or corrosive fluids. Its hygienic design and corrosion resistance are particularly suitable for these harsh application environments.

The advantages of positive screw pumps include:

Wide flow range

High delivery pressure

Can deliver high viscosity and granular fluids

Simple structure and easy maintenance

Low noise and stable operation

| Model | NM031BY01L06B | Rotor | 316L stainless steel |

| Flow range | 10-3000 L/h | Seal | EPDM |

| Working pressure | Max. 15 bar | Temperature range | -20°C to +120°C |

| Speed range | 50-1500 rpm | Protection level | IP55 |

| Torque | Max. 150 Nm | Motor power | 1.5 kW |

| Inlet | DN32 | Voltage | Three-phase 380-415V, 50 Hz |

| Outlet | DN32 | Dimensions (L x W x H) | 580 x 275 x 365 mm |

| Pump body | 316L stainless steel | Weight | Approx. 47 kg |

Various parameters of Netzsch NM031BY01L06B

Netzsch NM031BY01L06B screw pumps are widely used in:

Food and beverage industry: precise delivery of high-viscosity materials such as dairy products, sauces, syrups, etc.

Pharmaceutical and cosmetic industry: clean delivery of liquid raw materials and preparations, precise metering of chemical reagents

Chemical industry: reliable delivery of various corrosive materials such as acids, alkalis, solvents, etc.

Coating industry: uniform metering and delivery of paints, coatings, etc. to ensure product quality

Environmental protection field: collection and transportation of industrial wastewater, sludge, etc., and sample collection in environmental monitoring.

Hygienic design:

Adopts hygienic food-grade materials, meets industry standards, and ensures product hygiene and safety.

The flow channel design is smooth, without dead corners, easy to clean and disinfect, and meets strict hygiene requirements.

Excellent performance:

Wide flow range, can accurately deliver various fluids of 10-3000L/h.

Excellent high temperature resistance, can handle heat-sensitive materials up to 120°C.

Strong corrosion resistance, suitable for harsh media such as acids, alkalis, organic solvents.

Reliability:

Adopts high-quality stainless steel material, wear-resistant, corrosion-resistant, long service life.

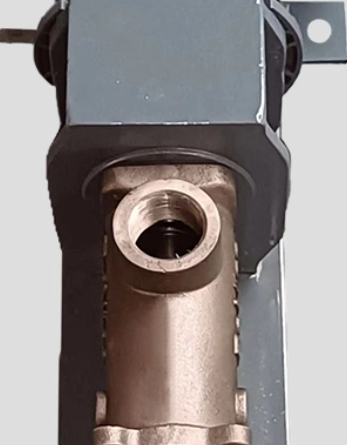

Unique sealing design effectively prevents leakage and ensures safe and reliable operation.

Easy maintenance:

Simple disassembly and assembly, convenient and quick maintenance.

Quick replacement of spare parts greatly reduces downtime.

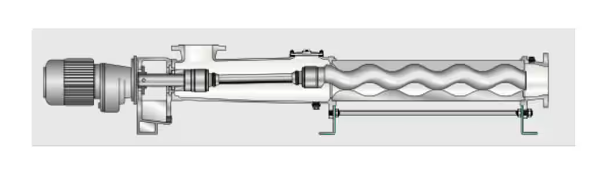

The helical rotor pump is a progressive cavity pump that works by rotating the helical rotor, pushing discrete portions of material through the unit as it seals against the helical walls

This helical action provides pulse-free flow, and because the helical rotor seals against discrete portions of the material, no valves are required

The flow rate is determined by the rotor speed and is independent of the outlet pressure

The pump works effectively in either forward or reverse direction

Can handle solid materials well

No valves to maintain

Smooth, pulse-free operation

Gently handles shear-sensitive products

Self-priming, can easily handle materials containing gas

Send Your Enquiry :