NM021BY01L06B Netzsch

NM021BY01L06B is a high-performance single screw pump, widely used in chemical, pharmaceutical, food and other industries where precise metering and delivery of various fluids are required.

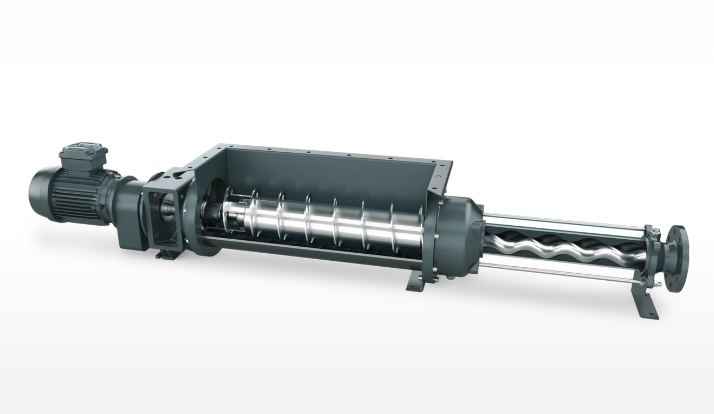

Netzsch NM021BY01L06B Progressing Cavity Pump – Precision Design and Superior Performance

NM021BY01L06B single screw pump is a high-quality pump product developed by Netzsch for the transportation of high-viscosity fluids. This pump is widely praised in the food, pharmaceutical, chemical and other industries for its excellent design and reliable performance.

The key components of Netzsch NM021BY01L06B single screw pump include stator and rotor. The stator adopts a special double helix internal surface design, which can effectively reduce the pulsation and pressure fluctuation of the fluid. The rotor adopts a single helix design, and the material is selected from high-quality steel. After precision processing and surface treatment, it ensures extremely high dimensional accuracy and wear resistance.This not only improves the running stability of the equipment, but also creates a quieter and more comfortable working environment.

The main technical parameters of Netzsch NM021BY01L06B single screw pump are as follows:

| Flow range | 0.1 – 3.5 m³/h |

| Working pressure | up to 15 bar |

| Temperature range | -20℃ – 140℃ |

| Speed range | 100 – 1200 rpm |

| Speed range | DN32 |

Food and beverage industry:

- Excellent hygienic design and fluid conveying performance, suitable for precise conveying of high-viscosity materials such as cheese and sauces.

- High temperature resistance can be used for the processing of heat-sensitive materials such as chocolate and syrup.

Pharmaceutical and cosmetics industry:

- Hygienic and clean, good anti-corrosion performance, suitable for pollution-free conveying of liquid raw materials and preparations.

- Excellent corrosion resistance, can convey harsh media such as chemical reagents, acid and alkali solutions.

Chemical and coating industry:

- Excellent corrosion resistance and wear resistance, suitable for conveying various corrosive materials such as acids, alkalis, solvents, etc.

- Low pulsation characteristics, suitable for precise metering in paint and coating production.

Environmental protection and environmental monitoring:

- Excellent corrosion resistance and anti-pollution performance, suitable for the collection and conveying of industrial wastewater and sludge.

- Precision conveying capacity can be used for sample collection and measurement in environmental monitoring.

Wide applicability

suitable for the temperature range of -20℃ to 140℃, and can withstand a maximum working pressure of 15bar. Therefore, it can easily cope with both low-temperature freezing and high-temperature steam.

Intelligent control

Users can flexibly set working parameters according to actual production needs, greatly improving production efficiency and flexibility.

Easy maintenance

The Netzsch NM021BY01L06B pump is very easy to disassemble and assemble, and each component can be quickly replaced, greatly reducing the difficulty of maintenance.

Hygienic and anti-corrosion properties

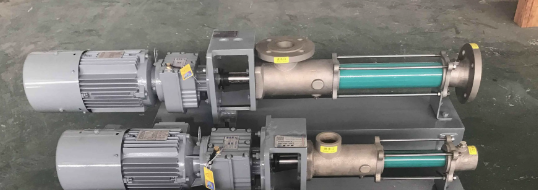

To meet the strict hygiene standards of the food, pharmaceutical and other industries, Netzsch NM021BY01L06B is made of all stainless steel hygienic materials.

People also ask :

Send Your Enquiry :