NM015BY01L06B is a widely used screw pump. The design of its core components, the stator and rotor, is the key to the pump performance.

Stator:

The Netzsch NM015BY01L06B stator uses high-quality insulating materials to ensure stable and reliable motor operation.The stator winding is precisely arranged to ensure high current transmission efficiency and reduce energy loss.

Rotor:

The rotor is the rotating part of the motor, which is driven to rotate by the magnetic field generated by the stator.

The rotor of Netzsch NM015BY01L06B is made of advanced materials and has excellent wear resistance and high temperature resistance.

The reasonable design of the rotor ensures the balance and stability of the motor during operation.

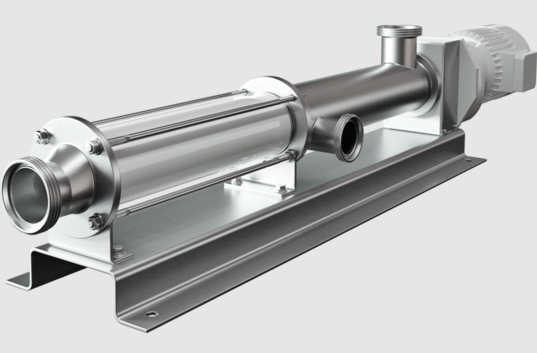

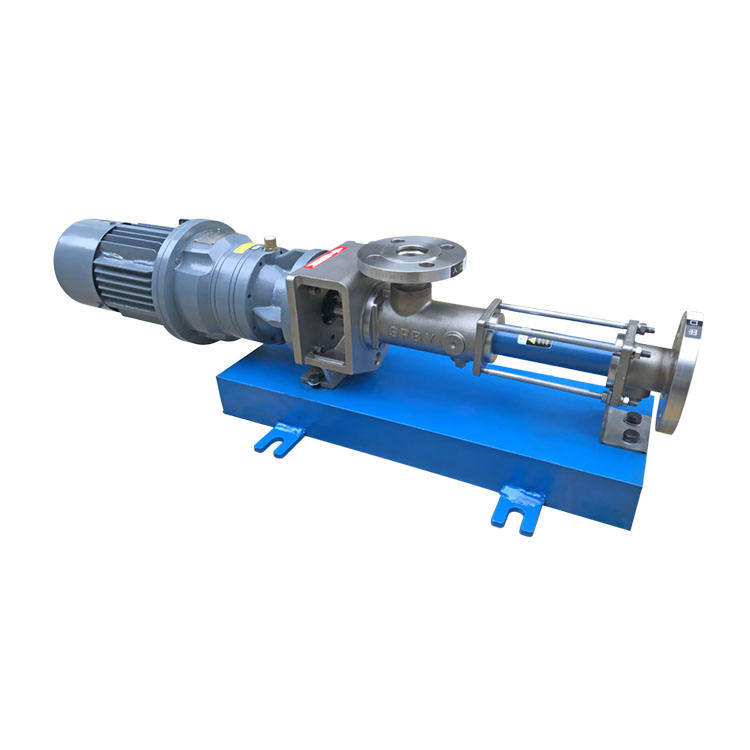

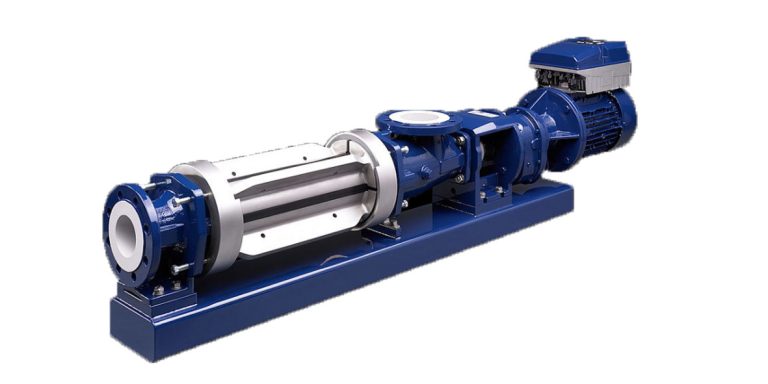

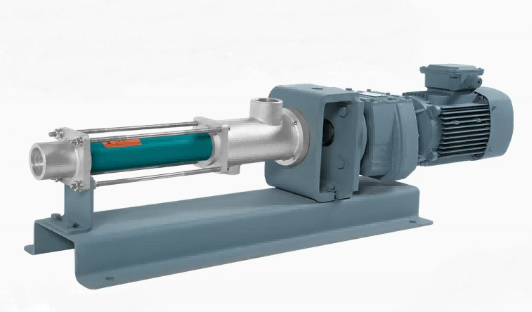

NEMO BY direct-connected type

Technical parameters: Flow rate up to 400m3/h, pressure up to 24bar

Performance characteristics: The pump is directly connected to the reducer, with a compact structure and low investment, use and maintenance costs. Four rotor/stator combinations are available for selection according to different applications.

Application range: It can be used for conveying various high-viscosity and solid particle-containing media in sewage, food, and chemical industries.

| Performance | variable frequency |

| Flow rate | 0.3 m3/h |

| Suction diameter | 40 mm |

| Discharge diameter | 40 mm |

| Speed | 290 rpm |

| Lift | 30 m |

| Pump length | 340 mm |

| Working temperature | 30 ℃ |

| Discharge pressure | 0.5 Mpa |

| Installation | flange connection |

| Pump housing | stainless steel 316L |

| Rotor | stainless steel 316L |

| Bearing | ball bearing |

| Seal | fluororubber (FKM) |

Performance characteristics:

Rated power: High power output, suitable for various industrial applications.

Excellent efficiency: High-efficiency design, energy-saving and environmentally friendly.

High reliability: Strict quality control, reliable performance and long life.

The excellent performance and reliability of Netzsch NM015BY01L06B stator rotor assembly make it the first choice in many industrial applications, providing stable power support for the production process.

Send Your Enquiry :