Netzsch NM021BY02S12B Stator

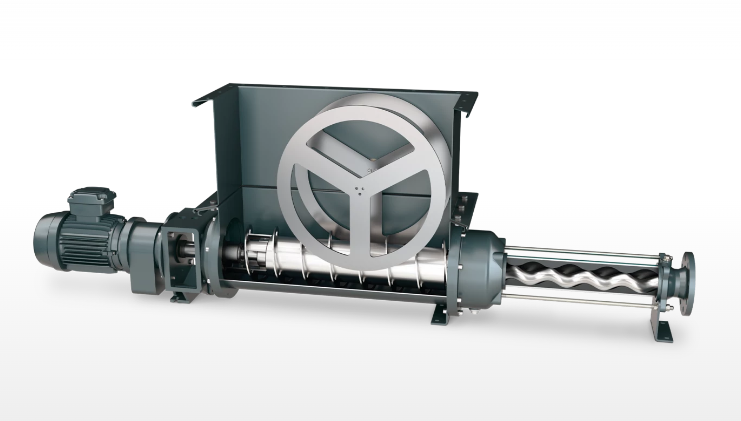

The stator is a key component in the screw pump, which provides a sealed chamber for the rotor.

Material

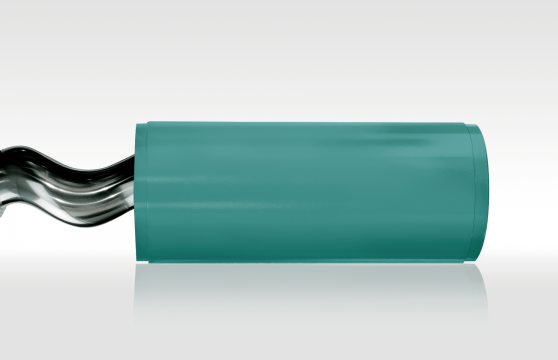

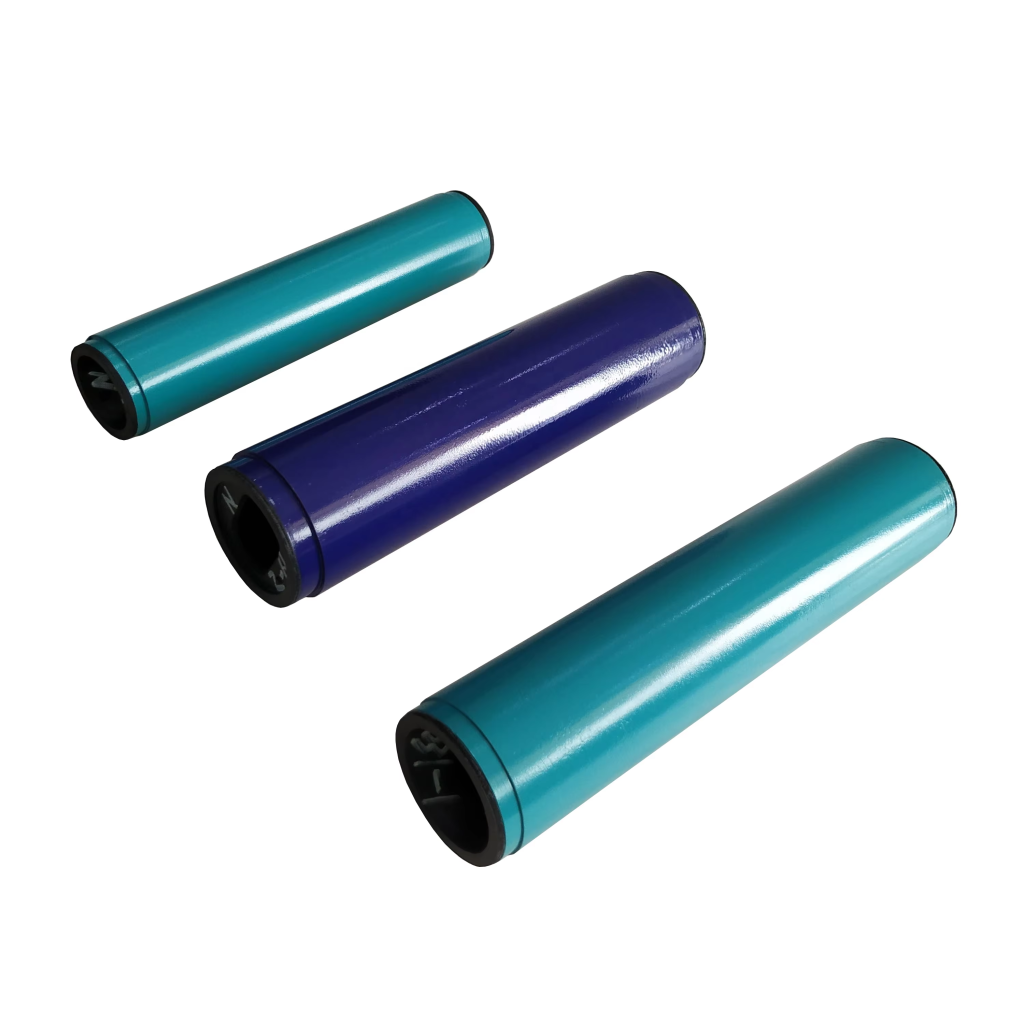

The stator is usually made of elastic polymer materials such as rubber, polyurethane, etc. These materials have good wear resistance, chemical stability and sealing performance.

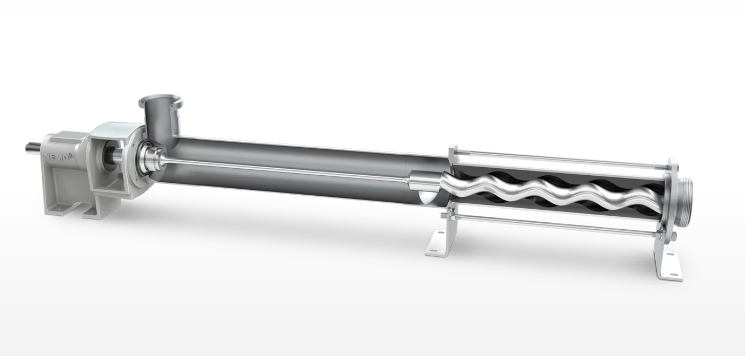

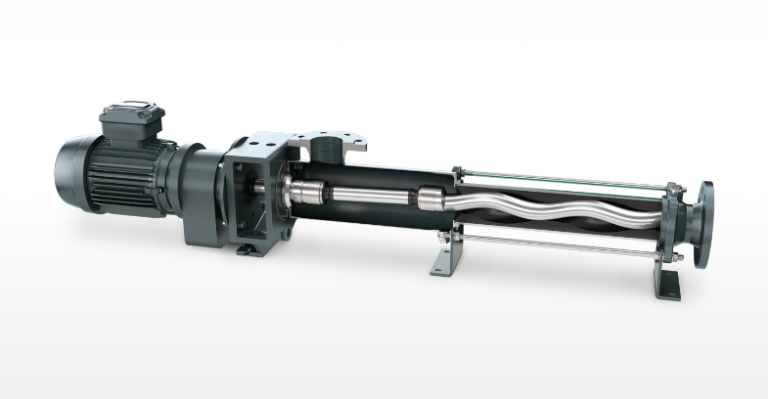

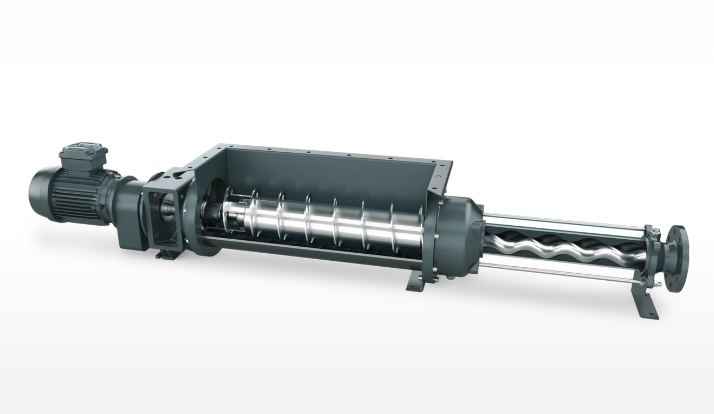

structure

The inner wall of the stator is spiral-shaped, matching the spiral shape of the rotor

This special internal structure can form a series of sealed chambers for conveying and sealing liquids

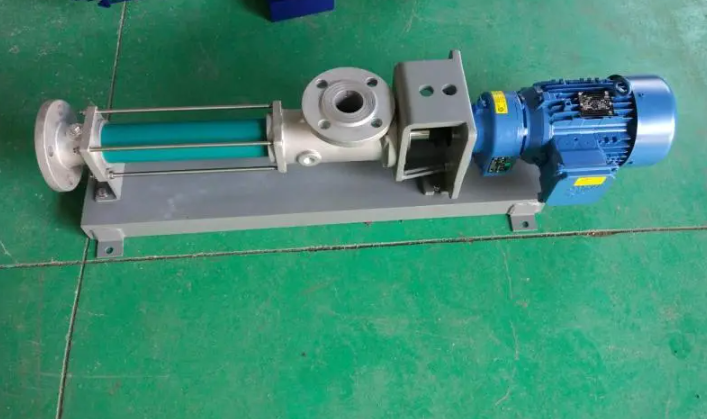

Installation

The stator is usually fixed inside the pump body shell

There will be a very small gap between the stator and the rotor, usually around 0.1-0.5mm

Sealing

The stator material and structural design can ensure good sealing when the rotor rotates

The elasticity of the stator can absorb vibration and impact during the movement of the rotor, improving the stability of the pump.

Maintenance

The stator is one of the vulnerable parts of the pump. The wear of the stator will cause leakage or reduced efficiency. It needs to be regularly inspected and replaced during long-term use. The replacement of the stator requires professional maintenance personnel to ensure the normal operation of the pump.

In the Netzsch NM021BY02S12B pump, the precise matching of the rotor and stator, as well as the optimized spiral shape, ensures that the liquid is smoothly transported under low pulsation and low shear stress conditions. The rotor provides driving force and the stator provides sealing, and the two work together to bring out the excellent performance of the screw pump. This design is suitable for a variety of viscous liquid delivery applications.

People also ask

Send Your Enquiry :