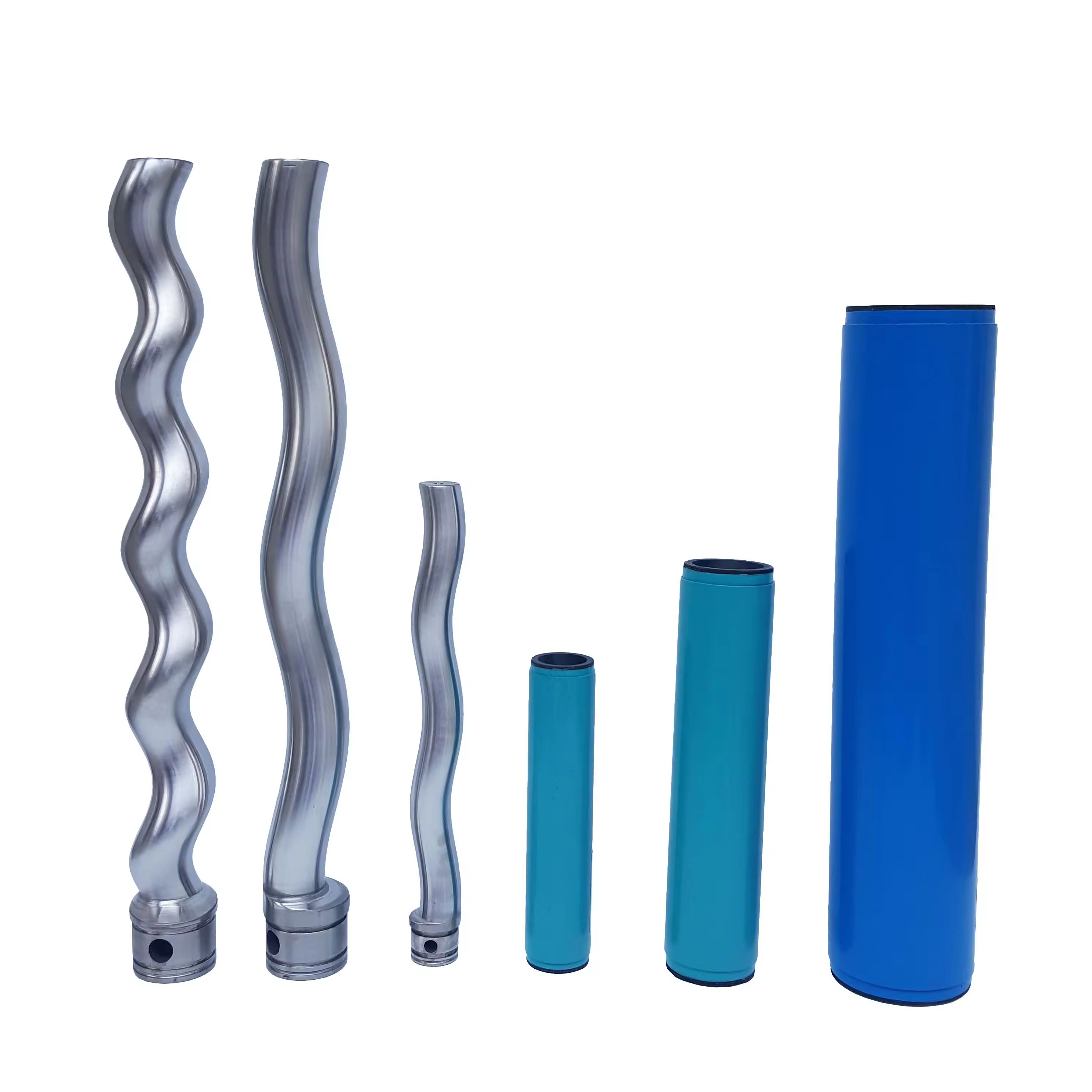

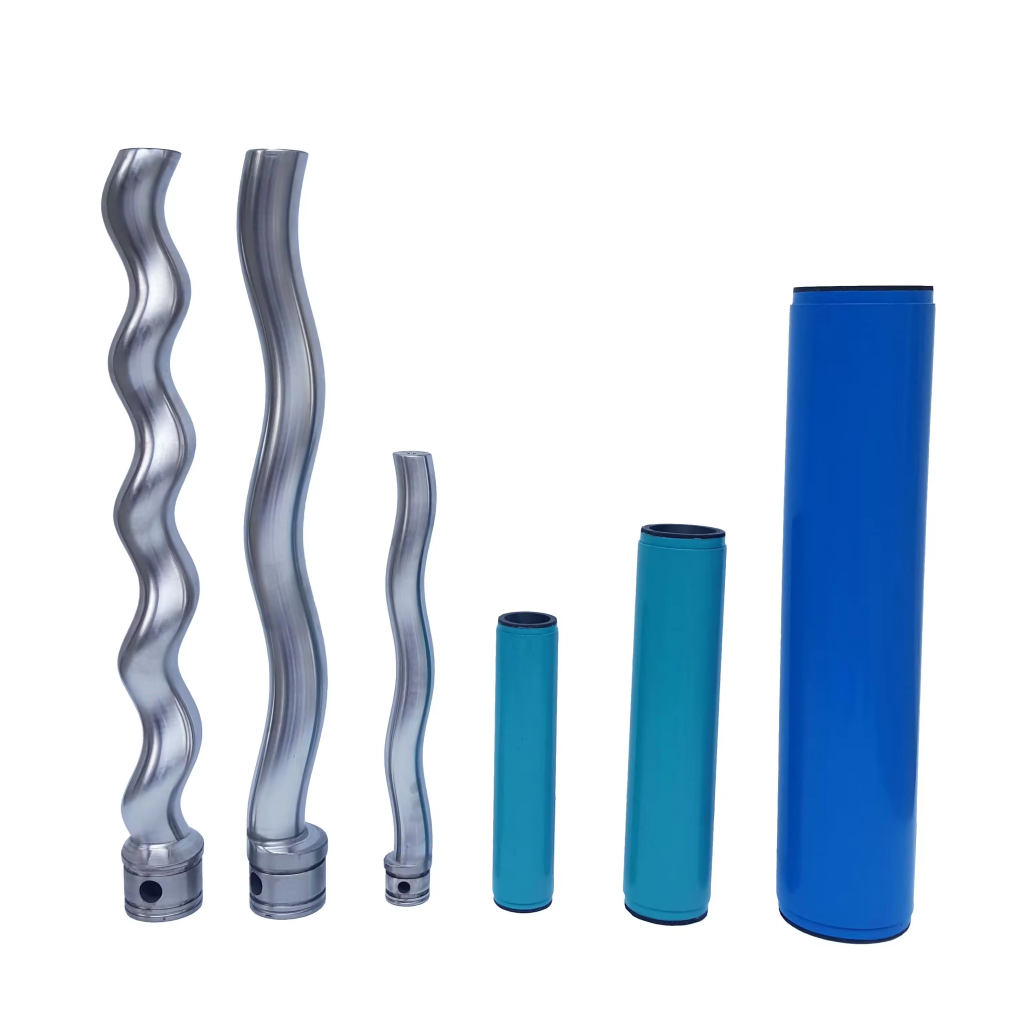

NM038BY02S12B Rotor

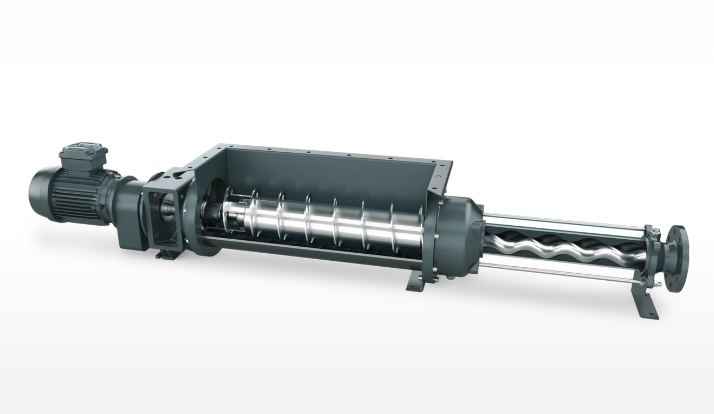

The rotor of Netzsch NM038BY02S12B screw pump is the core component. It is driven by the motor to rotate and cooperate with the stator to form a closed pump chamber, thereby driving the fluid delivery.

The following is a detailed introduction to the rotor of NM038BY02S12B:

Design and function:

The rotor is the core component of NM038BY02S12B. It is driven by the motor to rotate and cooperate with the stator to form a closed pump chamber, thereby driving the fluid delivery.

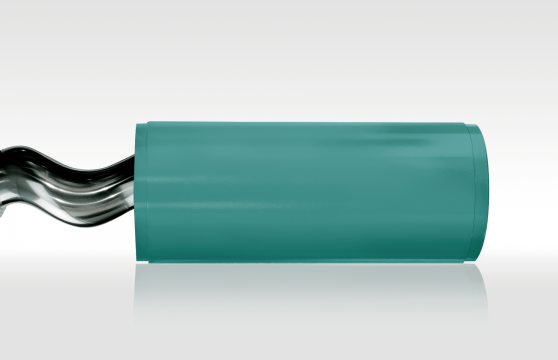

The spiral shape design enables the rotor to effectively absorb the liquid and compress it for delivery, ensuring the stable delivery of the fluid under low pulsation and low shear stress conditions.

Material and manufacturing:

The rotor is made of high-quality alloy steel material, which has good wear resistance and corrosion resistance after precision machining and surface treatment.

The high surface finish and precise shape ensure the sealing performance between the rotor and the stator.

Features and advantages:

The double helix structure can smoothly and continuously deliver liquid.

The stainless steel material gives the rotor excellent wear resistance and corrosion resistance, and adapts to high pressure and high temperature working environment.

Careful dynamic balancing design ensures almost no vibration and noise during high-speed operation.

It works closely with the stator to form a sealed liquid chamber, which improves the pump’s delivery efficiency.

Maintenance and replacement:

Since the rotor is in direct contact with the medium, wear and corrosion will directly affect the service life of the pump. Regular inspection and timely replacement of the rotor are essential.

The rotor of the Netzsch NM038BY02S12B screw pump is a precise and durable core component. Its excellent design and material ensure the efficient and stable operation of the pump. The special spiral shape and high-quality materials of the rotor enable the pump to reliably transport liquids in various working environments, ensuring the smooth flow of fluids in the system.

people also ask

Send Your Enquiry :