MD0005-24

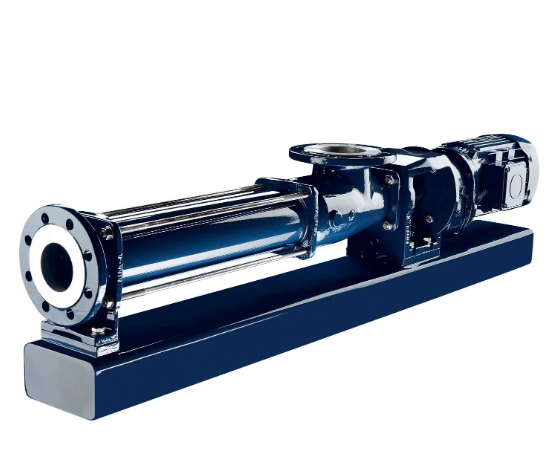

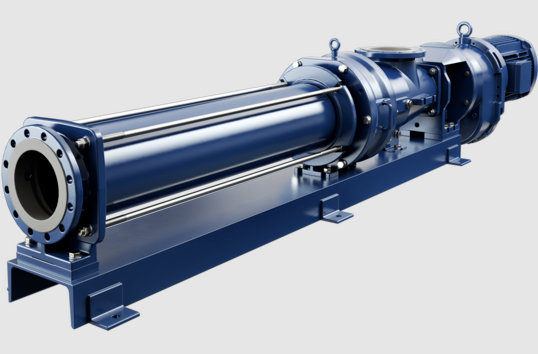

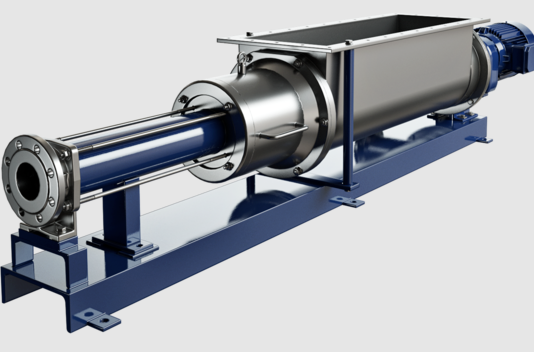

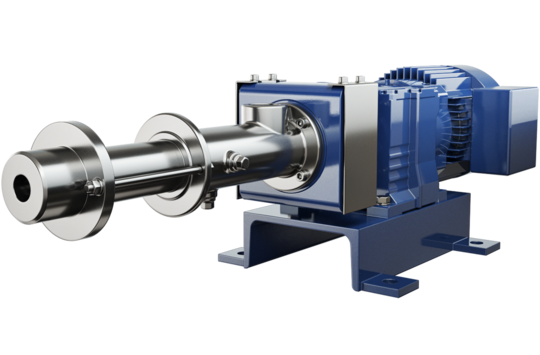

MD0005-24 adopts a new modular design concept, integrating the company’s valuable experience accumulated in the field of sewage treatment over the years. The equipment consists of core components such as pump body, rotor, stator, etc., and has excellent operating stability and service life. It is particularly worth mentioning that seepex MD0005-24 is equipped with an intelligent control system that can monitor the equipment status in real time and issue fault warnings in time, greatly improving the reliability of the equipment.

Technical Specs

- Max Flow Rate (LPM): 0.216

- Min Flow Rate (LPM): 0.003

- Max Flow Rate (GPH): 3.4

- Min Flow Rate (GPM): 0.0008

- Max Flow Rate (GPM): 0.057

- Min Flow Rate (GPH): 0.05

- Max Flow Rate (LPH): 12.9

- Min Flow Rate (LPH): 0.2

- Self-Priming: Yes

- Max Motor RPM (rpm): 600

- Min Motor RPM (rpm): 30

- Suction Lift Wet (in Hâ O): 108

- Suction Lift Wet (mm of Hâ O): 2700

- Suction Lift Wet (in Hg): 7.9

- Suction Lift Wet (mm Hg): 559

- Motor Type: Variable-frequency drive Power (VAC): 115

- Wetted Materials: 316

- Stainless Steel, Buna-N Max Temperature ( F): 200

- Max Temperature ( C): 93

- Viscosity, Max (cP): 40000

- Motor hp: 1/2

- Description: Industrial progressing cavity pump with an AC VFD drive, 0.05 – 3.4 GPH

Excellent chemical resistance, pulseless flow, and low shear Gentle low-shear fluid transfer capable of pumping small particles without damaging product Pumps can handle a variety of polymers and chemicalsideal for pharmaceutical and water treatment applications Sanitary models approved for 3A sanitary applications and can be cleaned in place A Pump heads can be mounted on a NEMA 56C frame motor. Pump heads can also be directly connected or belt driven by an AC or DC motor, gasoline engine (min. 2 hp), or air motor. B Pumps are close-coupled to an AC motor with an integral VFD controller. The VFD controller features a hands-off-auto switch, providing speeds from 30 to 600 rpm. C Pumps feature a -hp motor with 230/460 VAC input power. This configuration has a mechanical variable-speed drive that adjusts from 0 to 1000 rpm. Options are broken up into an industrial and a sanitary categories.

People also ask

Send Your Enquiry :