Parameters

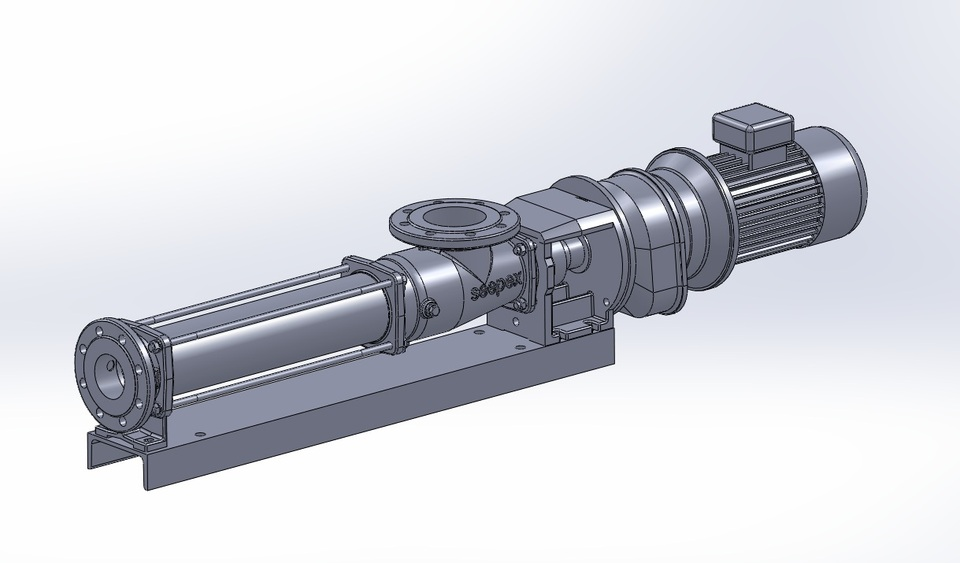

- Brand: SEEPEX

- Performance: Wear-resistant

- Weight: 50kg

- Drive mode: Electric

- Power: 1.5kW

- Number of impellers: Single stage

- Pump shaft position: Horizontal

- Pressure: 0.6Mpa

- Lift: 60m

- Suction diameter: DN65(mm)

- Discharge diameter: DN50(mm)

- Suction head: 10m

- Working temperature: Normal temperature

- Material: Stainless steel

- Flow rate: 4m³/h

- Model: BN5-6L

Introduction

Seepex BN5-6L has high working efficiency, stable flow rate and uniform pressure, which reduces the shear force of the liquid and protects sensitive materials. At the same time, the pump also has good self-priming ability, without the need for additional suction devices, saving installation space and cost.

The rotor is the core part of the BN5-6L. The low-pressure area generated by its rotational motion can effectively suck in the liquid to ensure the continuous operation of the pump. The stator surrounds the outside of the rotor and uses its elastic material to create a sealed delivery channel to reduce liquid leakage and pressure loss.

Seepex BN5-6L performs well in conveying high-viscosity fluids and can handle a variety of fluids, including slurries and particulates.

In terms of energy saving, Seepex BN5-6L reduces energy consumption through optimized design and is suitable for applications with long-term operation. BN5-6L is also very easy to maintain. Due to its modular design, users can easily perform daily inspections and replace some parts, reducing the complexity of maintenance.

people also ask

Send Your Enquiry :