Parameters

Brand: SEEPEX

Pressure: 0.6Mpa

Pump shaft position: horizontal

Impeller suction mode: single suction

Drive mode: electric

Performance: no leakage

Transport medium: sewage pump, impurity pump

Flow rate: 130m3/h

Lift: 60m

Working pressure: 0.4MPa

Voltage: 380V

Material: cast steel

Model: BN130-6L

Introduction

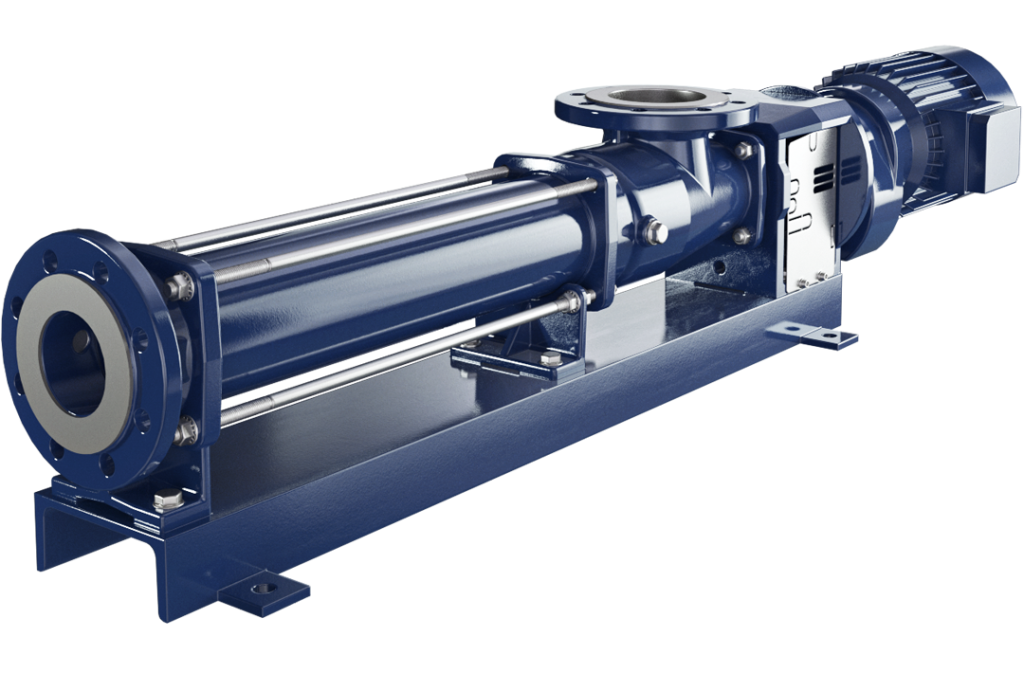

Seepex BN130-6L has good adaptability. It is designed to adapt to different working environments and fluid characteristics, and users can adjust the operating parameters of BN130-6L according to their needs. This flexibility allows Seepex BN130-6L to realize its potential in many industries, including petroleum, pharmaceuticals and biotechnology.

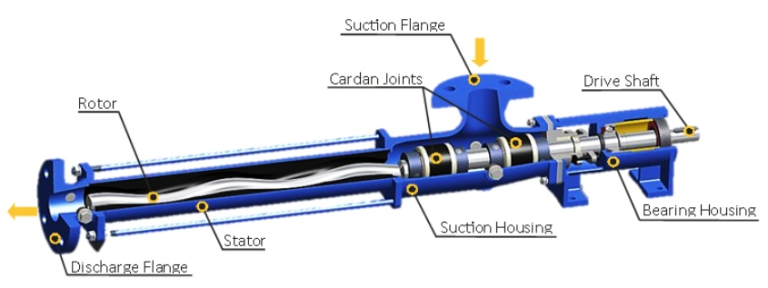

The rotor and stator are closely matched to form a closed pump chamber. This design allows the liquid to maintain good stability and uniformity when flowing in the pump.

The working mode of BN130-6L can be quickly adjusted according to the changes in the production line to maintain the continuity and efficiency of production. Even in a high-intensity working environment, the wear-resistant material and design of the pump body greatly increase its service life.

In terms of maintenance, the design of Seepex BN130-6L also fully considers the needs of users. When the pump fails or its performance deteriorates, users can quickly check and replace related parts to ensure the continuous operation of the production line. This low-maintenance design greatly improves the efficiency of BN130-6L. It greatly reduces the difficulty and cost of maintenance.

people also ask

Send Your Enquiry :